Process and device for increasing yield of acetone-hydrogenation isopropanol production

A technology of isopropanol and acetone, applied in the field of improving the yield of isopropanol produced by acetone hydrogenation, can solve the problems of high production cost, decreased yield of isopropanol, complicated operation, etc., and achieves energy saving, energy consumption reduction, The effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

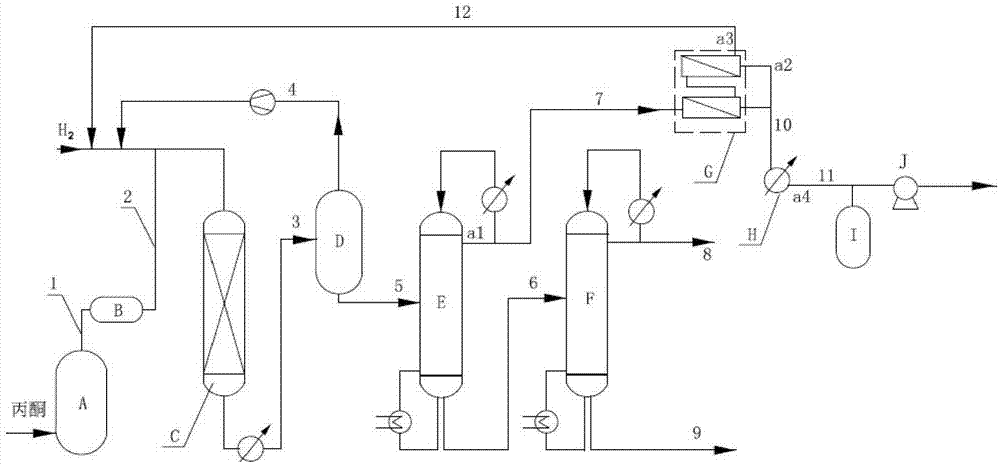

[0024] Such as figure 1 Shown, a kind of acetone hydrogenation produces the device of isopropanol yield, comprises hydrogenation reactor C, the first rectification tower E, the second rectification tower F, the outlet of hydrogenation reactor C passes through gas The liquid separator D is connected to the first rectification tower E, the top outlet of the first rectification tower E is connected to the pervaporation device, and the retentate side of the pervaporation device G is connected to the feed port of the hydrogenation reactor C, and the permeation The retentate side of the vaporization device G is connected with a permeate tank I and a vacuum pump J, and the bottom outlet of the first rectification tower E is connected to the second rectification tower F, and the bottom of the second rectification tower F is isopropanol Evaporator A is installed in front of the hydrogenation reactor C at the material outlet, and the top outlet of the evaporator A is connected to the h...

Embodiment 2

[0030] use as figure 1In the device shown, the reaction raw material acetone (5000kg / h) enters the evaporator A to be vaporized, and the vaporized raw material stream 1 enters the superheater B to be further overheated, so as to prevent a small amount of entrained liquid foam from entering the hydrogenation reactor and causing catalyst damage. The superheated acetone steam 2 and hydrogen enter the hydrogenation reactor C together with the circulating hydrogen 12. The feed ratio of hydrogen and acetone is 2:1, and the hydrogenation reaction is carried out in the presence of a catalyst. The acetone mainly generates isopropanol and simultaneously generates Trace amounts of by-products such as diisopropyl ether, water and 4-methylpentanol. The effluent 3 of the reactor enters the gas-liquid separator D after being condensed, and the unreacted hydrogen is separated, and is compressed and used as the circulating hydrogen 4 for recycling. The condensate 5 is sent to the first recti...

Embodiment 3

[0033] use as figure 1 In the device shown, the reaction raw material acetone (5000kg / h) enters the evaporator A to be vaporized, and the vaporized raw material stream 1 enters the superheater B to be further overheated, so as to prevent a small amount of entrained liquid foam from entering the hydrogenation reactor and causing catalyst damage. The superheated acetone steam 2 and hydrogen enter the hydrogenation reactor C together with the circulating hydrogen 12. The feed ratio of hydrogen and acetone is 6:1, and the hydrogenation reaction is carried out in the presence of a catalyst. The acetone mainly generates isopropanol and simultaneously generates Trace amounts of by-products such as diisopropyl ether, water and 4-methylpentanol. The effluent 3 of the reactor enters the gas-liquid separator D after being condensed, and the unreacted hydrogen is separated, and is compressed and used as the circulating hydrogen 4 for recycling. The condensate 5 is sent to the first rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com