Multi-branch structure demulsifier of aromatic ring core

A multi-branched, demulsifier technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of reducing the utilization rate of pipelines and equipment, corrosion damage of equipment pipelines, increasing viscosity, etc., and achieve good hydrophilic and hydrophobic performance and interface activity. , good interface destruction ability, showing the effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further clarified in conjunction with embodiment.

[0028] 1. Raw material synthesis:

[0029] (1) Phenolic amine resin;

[0030] (2) Multi-branched polyester intermediates with aromatic ring core;

[0031] (3) Aromatic ring core Dendrimer multi-branch structure initiator;

[0032] (4) Polyether demulsifier with aromatic ring core Dendrimer multi-branched structure;

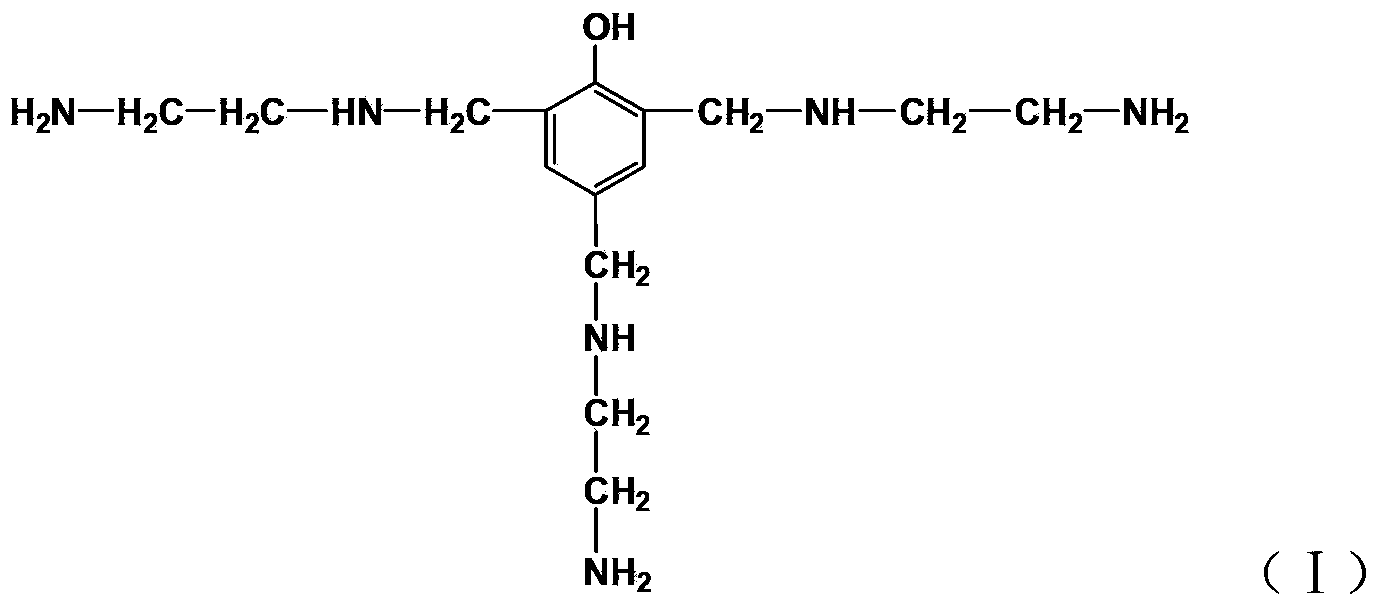

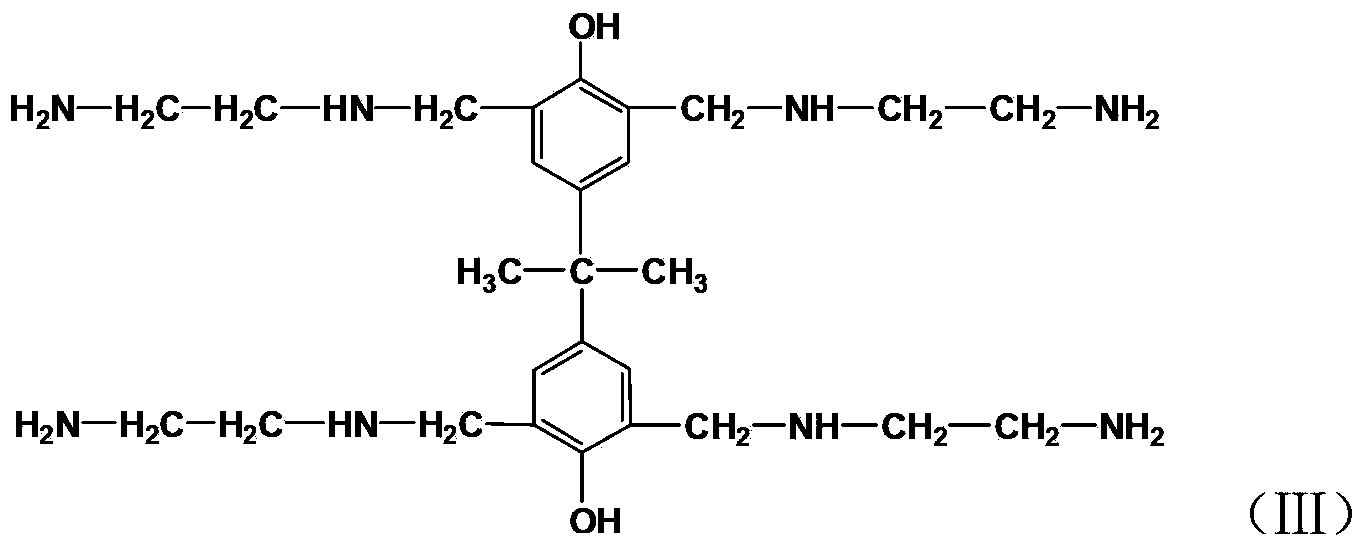

[0033] The chemical formulas of the reaction step (1) phenolamine resin in the present invention are shown in (I), (II) and (III).

[0034]

[0035] Formula (I) is the structural formula of phenolamine resin synthesized from phenol, ethylenediamine and formaldehyde.

[0036]

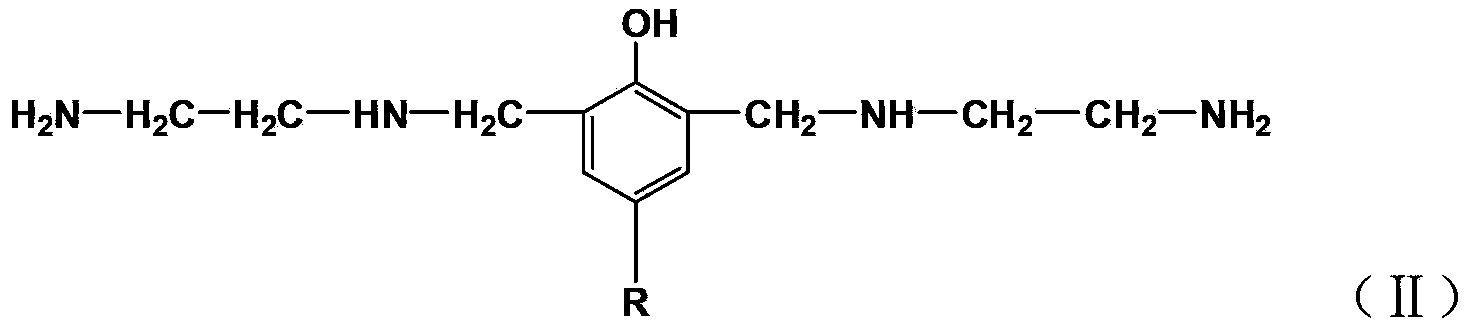

[0037] Formula (II) is the structural formula of phenolamine resin synthesized from alkylphenol, ethylenediamine and formaldehyde. In the formula, R is a propyl group, a butyl group, a pentyl group, a heptyl group, an octyl group, a nonyl group, a decyl group or a 11-18 long-chain alkyl group.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com