A fiber-based sewage decolorization and purification material and its preparation method

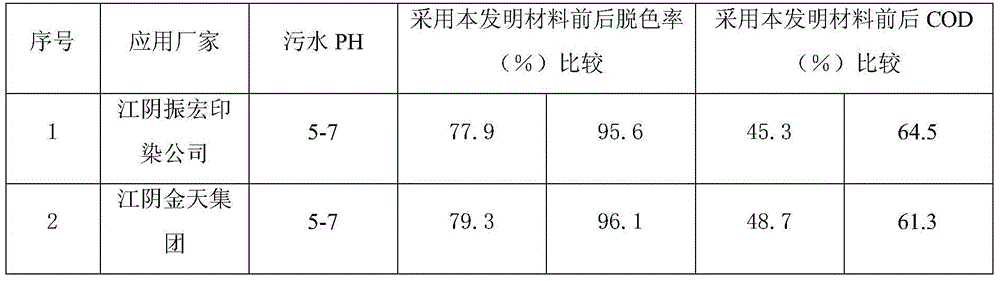

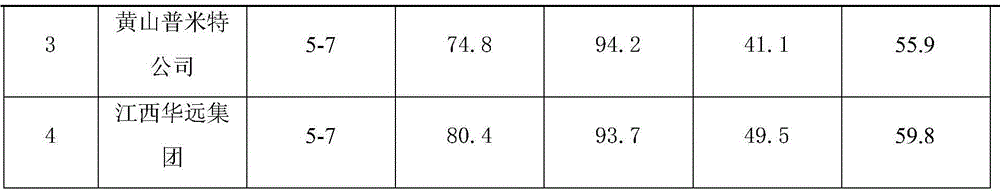

A purification material and fiber-based technology, which is applied in the field of sewage treatment material preparation, can solve the problems of no breakthrough in biological decolorization and high treatment cost of advanced oxidation method, achieve high decolorization rate and COD removal rate, reduce sludge transportation costs, The effect of improving the flocculation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Non-limiting examples are described below. For the convenience of description, hereinafter referred to as parts by mass.

[0052] (1) Preparation of Modified Additive A

[0053] Take 275 parts of magnesium sulfate and 725 parts of magnesium chloride and mix them uniformly.

[0054] (2) Preparation of modified fibers

[0055] 1. Preparation of modified cellulose plant fiber

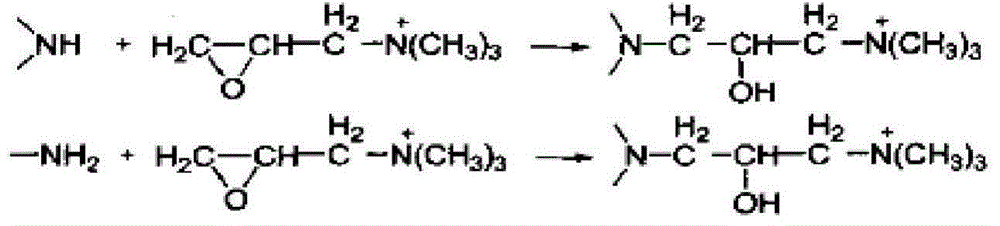

[0056] The cellulose is grafted with cationic groups to make it positively charged, which can significantly improve the rapid combination of negatively charged dyes in sewage with adsorbent cellulose, and achieve the purpose of decolorization from water.

[0057] Preparation of modified cellulose plant fibers: The graft copolymerization of cellulose can be divided into three categories: free radical polymerization, ionic polymerization and condensation or addition polymerization. Graft copolymerization can improve the structure and properties of cellulose and its derivatives. The invention can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com