Metal/rare earth carbonate-based solid carbonate electrode and preparation method thereof

A technology of rare earth carbonates and carbonates, which is applied to the electrochemical variables of materials, material analysis through electromagnetic means, and measurement devices, which can solve problems such as deviations between calculation results and actual conditions, and achieve easy integration and use, and simple preparation methods , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

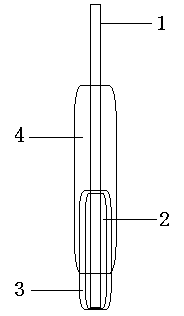

[0032] The steps of the preparation method of the solid carbonate electrode based on metal / rare earth carbonate are as follows:

[0033] 1) Clean the metal wire 1 with a diameter of 0.5 to 1 mm and a length of 5 to 15 cm in acetone and dilute acid in order to remove surface oil and oxide film, then wash with deionized water and dry;

[0034] 2) Dissolving soluble carbonate in water to prepare a soluble carbonate solution with a concentration of 3% to 10% by mass;

[0035] 3) The metal wire is used as the working electrode, that is, the anode, the graphite is used as the reference electrode, and the Pt sheet is used as the auxiliary electrode, that is, the cathode, connected to the electrochemical workstation, and the above three electrodes are immersed in the soluble carbonate solution. Sweep potentiometric method with a scan rate of 30 to 80mVs -1 , the potential range is 0 to 1V, scanning 1 to 10 cycles, metal carbonate precipitation is formed on the surface of the wire; af...

Embodiment 1

[0050]1) Clean the silver wire 1 with a diameter of 0.5 mm and a length of 10 cm in acetone and dilute hydrochloric acid in order to remove surface oil and oxide film, then wash with deionized water and dry;

[0051] 2) Potassium carbonate is dissolved in water to prepare a potassium carbonate solution with a mass percentage concentration of 3%;

[0052] 3) Take the silver wire 1 as the working electrode (anode), the graphite as the reference electrode, and the Pt sheet as the auxiliary electrode (cathode), connect it to the electrochemical workstation, immerse the above three electrodes in the carbonic acid solution, and use the cyclic scanning potential method with a scan rate of 50mVs -1 , with a potential range of 0 to 1V, scanning for 8 cycles, forming a silver carbonate precipitate on the surface of the silver wire 1; washing with water after the electroplating is completed, and then drying at room temperature or vacuum drying;

[0053] 4) Dissolving lanthanum trichlori...

Embodiment 2

[0062] 1) Clean the cadmium wire 1 with a diameter of 0.5 mm and a length of 10 cm in acetone and dilute nitric acid in order to remove surface oil and oxide film, then wash with deionized water and dry;

[0063] 2) Sodium bicarbonate is dissolved in water to prepare a sodium bicarbonate solution with a concentration of 10% by mass;

[0064] 3) Use cadmium wire 1 as the working electrode (anode), graphite as the reference electrode, and Pt sheet as the auxiliary electrode (cathode), connect it to the electrochemical workstation, immerse the above three electrodes in the carbonic acid solution, and use cyclic scanning potential method with a scan rate of 50mVs -1 , with a potential range of 0 to 1V, scanning for 5 cycles, forming a cadmium carbonate precipitate on the surface of the cadmium wire 1; washing with water after the electroplating is completed, and then drying at room temperature or vacuum drying;

[0065] 4) Dissolving yttrium nitrate in water to prepare a solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com