A kind of instant kudzu powder rich in puerarin and preparation method thereof

A technology of puerarin and puerarin starch, which is applied in food preparation, food shaping, food ingredients containing natural extracts, etc., can solve the problems of ineffective utilization of puerarin and low content of pueraria isoflavones, etc., to ensure taste and solubility , puerarin and other substances with high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

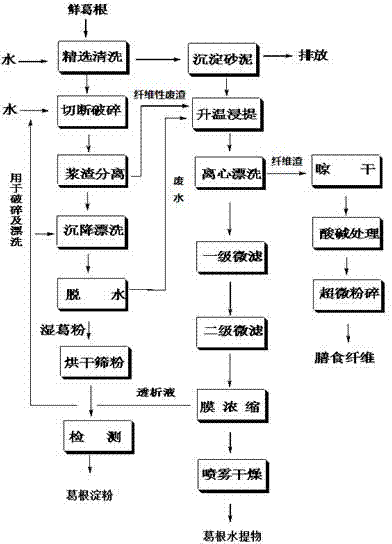

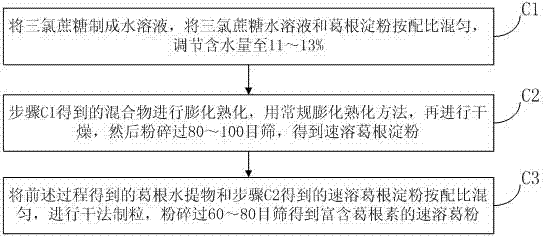

Method used

Image

Examples

Embodiment 1

[0051] Take 1 kg of fresh kudzu, remove the rotten part, clean it, chop it up, use about 8 kg of water, squeeze and crush it, add water to wash the powder, filter, put the slurry into the settling tank, settle for 12 hours, separate the mother liquor, and remove sand Rinse the sedimented starch 3 times with about 3 kilograms of water in total, settle for 3 hours after each rinsing, take out the wet starch and control the temperature at 70-80 ° C for 4 hours in vacuum to get 190 grams of kudzu starch. During the above process, 12 kg of waste water (mother liquor and rinsing liquid) and some fibrous waste residue (about 0.2-0.3 kg) are produced.

Embodiment 2

[0053] The fibrous waste slag obtained in Example 1 was added to a 20L jacketed glass kettle with stirring, and all 12 kg of waste water was added. Under stirring, the jacketed hot water was heated to a temperature of 50°C in the kettle, and kept for leaching for 1 hour. Filtrate while hot to obtain filtrate and fiber slag, rinse and dry the fiber slag with about 1 kg of water for later use, combine the filtrate and lotion, and pump to two-stage microfiltration membrane (double-layer microporous membrane filter) for filtration to obtain Microfiltrate (the pore diameter of the primary microfiltration membrane is 5 microns, and the pore diameter of the secondary microfiltration membrane is 2 microns), and the microfiltrate is controlled at room temperature at a pressure of 3.0-3.5 MPa into the membrane and a pressure of 2.5-3.0 MPa out of the membrane. Enter the reverse osmosis membrane (reverse osmosis system) for membrane concentration. When the weight of the concentrated solut...

Embodiment 3

[0055] Embodiment three is basically the same as embodiment two, the difference is that the waste water is divided into 3 times (each time 4 kg) to extract fibrous waste residue, finally obtain 32 grams of kudzu root water extract, the puerarin content is 12.5% through HPLC detection, The recovery rate of puerarin was 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com