Graphene oxide porous composite material and preparation method thereof

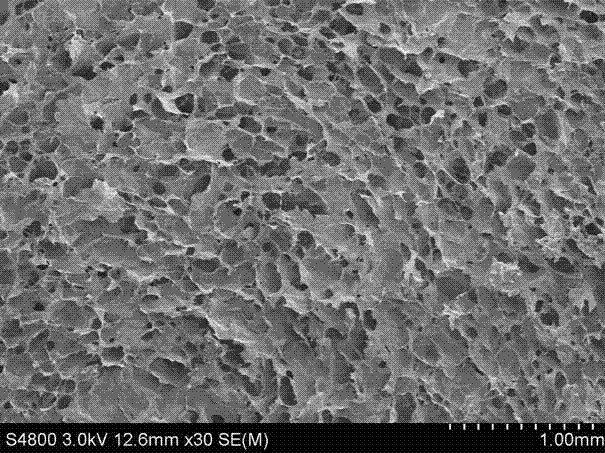

A porous composite material, graphene technology, applied in the field of graphene oxide porous composite material and its preparation, to achieve the effect of good biocompatibility, maintaining shape and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

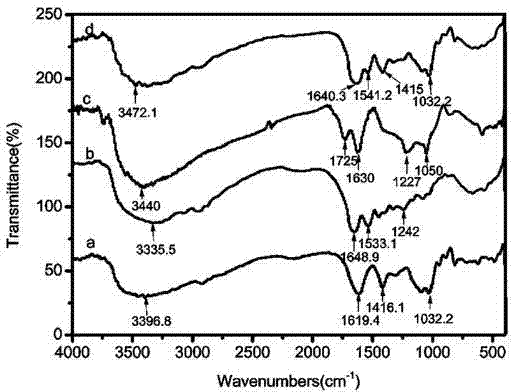

Method used

Image

Examples

Embodiment 1

[0036] First, mix the gelatin solution with a concentration of 0.5wt% into the sodium alginate solution with a concentration of 4wt%, and stir it with a magnetic force at 400r / min for 90min at 35°C, then mix the graphene oxide solution with a concentration of 2wt% at 1ml / min Add it into the above solution at a speed of 100°C, stir for 30 minutes, adjust the pH value of the mixed solution to 5.33 with a volume concentration of 1% acetic acid solution, and let it stand for defoaming to obtain a graphene oxide / sodium alginate / gelatin blend sol.

[0037] Then slowly add calcium chloride solution with a concentration of 4wt% to the blended sol, stir evenly, then transfer it to a mold and let it stand for crosslinking for 240 minutes, the blended sol turns into a gel, freeze-dry, and obtain a graphene oxide porous composite material.

Embodiment 2

[0039]First, the gelatin solution with a concentration of 7wt% was mixed into the sodium alginate solution with a concentration of 1wt%, and stirred at 50°C for 60min with a magnetic force of 600r / min. Subsequently, the graphene oxide solution with a concentration of 2wt% was added to the above solution at a speed of 4ml / min, stirred for 50min, and then the pH value was adjusted to 4.73 with a hydrochloric acid solution with a volume concentration of 0.5%, and after standing for defoaming, graphene oxide was obtained. / sodium alginate / gelatin blend sol.

[0040] Then slowly add a calcium chloride solution with a concentration of 5wt% to the blended sol, stir evenly, then transfer to a mold to stand for crosslinking for 60 minutes, the blended sol is transformed into a gel, and freeze-dried to obtain a graphene oxide porous composite material.

Embodiment 3

[0042] Firstly, the gelatin solution with a concentration of 2wt% was mixed into the sodium alginate solution with a concentration of 1.5wt%, and stirred at 800r / min for 40min at 55°C with a magnetic force. Subsequently, a graphene oxide solution with a concentration of 2wt% was added to the above solution at a rate of 6ml / min, stirred for 90min, adjusted to a pH value of 5.87 with a volume concentration of 1% acetic acid solution, and left to defoam to obtain graphene oxide / alginic acid Sodium / gelatin blend sol.

[0043] Then slowly add calcium chloride solution with a concentration of 8.5wt% to the blended sol, stir evenly and then transfer to the mold to stand for crosslinking for 320min, the blended sol turns into a gel, and after freeze-drying, the graphene oxide porous composite material is obtained .

[0044] The present invention enumerates but is not limited to the specific embodiment scheme listed above. The graphene oxide porous composite material obtained through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com