Macroporous carbonized nickel catalyst, and preparation method and application thereof

A nickel carbide and catalyst technology, applied in the field of carbide catalyst preparation, can solve the problem that carbide materials are not yet reported, and achieve the effects of short cycle, simple operation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1 The preparation method of carboxyl modified colloidal crystal template

[0091] In this example, the carboxyl-modified colloidal crystal template was prepared according to the following method:

[0092] (1) Preparation of monodisperse carboxyl-modified polymethylmethacrylate (c-PMMA) microspheres by improved soap-free emulsion polymerization

[0093] Add 50ml of acetone and 150ml of deionized water to a tank equipped with a stirrer, reflux condenser, thermometer and N 2 In a 1000ml four-necked flask with a trachea, pass N 2 Vacuumize, add MMA and AA with a volume ratio of 25:1 (both monomers are purified by distillation under reduced pressure), and heat to 80°C. At the same time, 0.27g of initiator KPS and 0.45g of AIBN were weighed and dissolved in 150ml of water, heated to 80°C and added to a four-necked flask. N 2 After reacting for 1.5 h under protection, it was naturally cooled to room temperature under stirring, ultrasonically treated for 1.5 h, a...

Embodiment 2

[0098] The preparation method of embodiment 2 macroporous nickel carbide

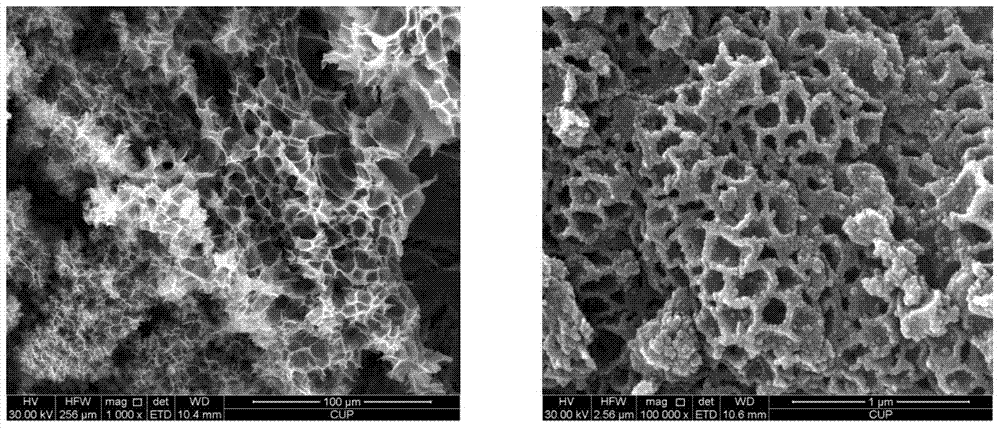

[0099]Weigh nickel nitrate, dissolve it in 10ml of methanol / ethylene glycol mixed solution (volume ratio 1:3), the molar ratio of nickel nitrate and methanol / ethylene glycol is 1:2, stir magnetically for 2 hours to obtain a homogeneous transparent solution, and obtain the catalyst precursor solution. This solution was used to impregnate 3 g of the dried c-PMMA colloidal crystal template prepared in Example 1 for 10 h. After the impregnation was complete, the excess precursor solution was removed by suction filtration, and then the template was placed in a vacuum oven to dry overnight. Finally, it is heated up to 750°C for calcination in an argon atmosphere, and kept at a constant temperature for 4 hours to obtain macroporous nickel carbide. The argon flow rate is 80ml / min, and the heating rate is 1°C / min.

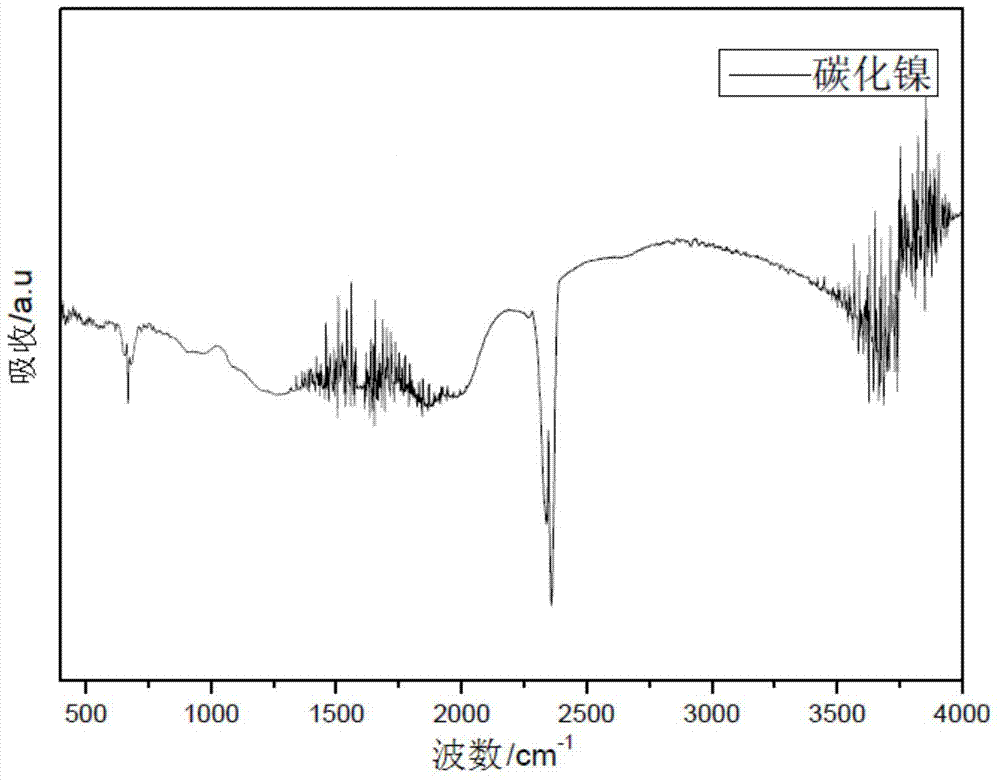

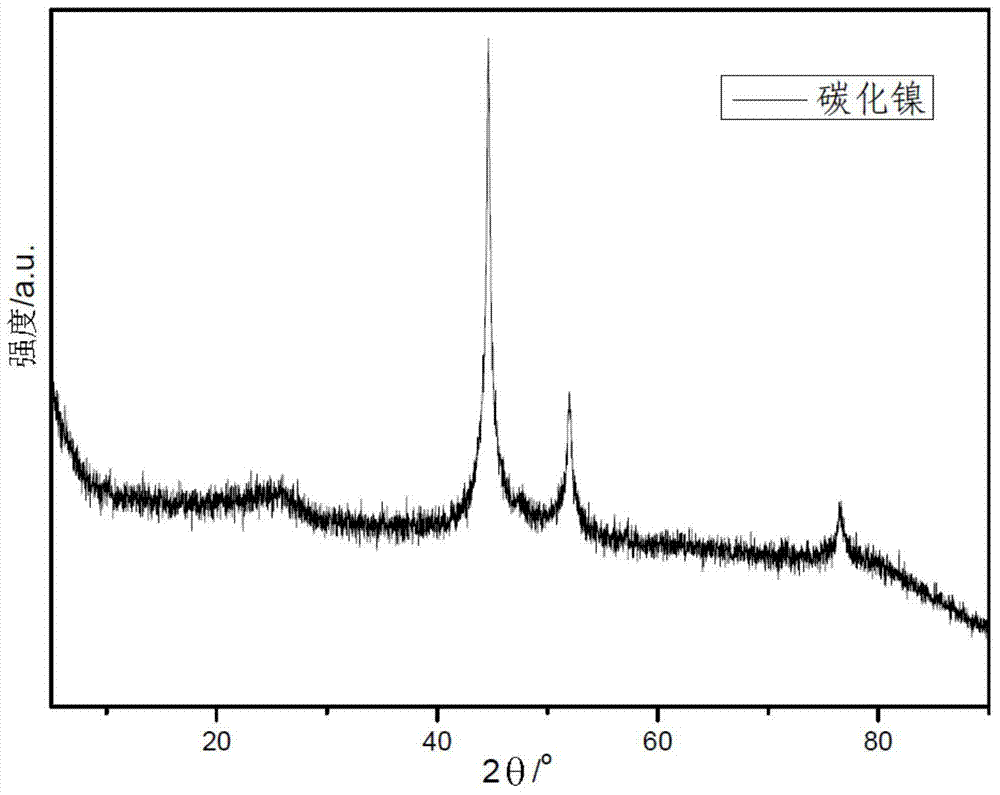

[0100] The X-ray diffraction spectrum and the infrared spectrum of the macroporous nickel carbi...

Embodiment 3

[0101] Example 3 The result of macroporous nickel carbide being used to catalyze and simulate hydrogen production by steam reforming of bio-oil

[0102] According to the following steps, the macroporous nickel carbide catalyst prepared in Example 2 is used to catalyze hydrogen production by steam reforming of bio-oil:

[0103] Put the macroporous nickel carbide catalyst into the fixed-bed reactor and feed 50% H 2 / N 2 Mixed gas, activate the catalyst for 2 hours at 450°C;

[0104] According to C 2 h 5 OH:C 6 h 5 OH:H 2 O=2:1:12 ratio, configure a mixed solution of simulated bio-oil;

[0105] The bio-oil mixed solution is preheated to 150°C, the reactor is heated to 450°C, the activation gas is stopped, and then the simulated bio-oil mixed solution is pumped into the reactor with a plunger pump to carry out the catalytic hydrogen production reaction.

[0106] Depend on Figure 4 The results show that the H in the prepared syngas 2 The content is as high as 65%. It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com