Nitrogen-doped graphene/nitrogen-doped carbon nanotube/tricobalt tetraoxide composite paper and preparation method thereof

A nitrogen-doped graphene and cobalt tetroxide technology is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve good application prospects, enhanced ORR catalytic performance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a preparation method of nitrogen-doped graphene / nitrogen-doped carbon nanotube / cobalt tetroxide composite paper, comprising the following steps:

[0043] a. Provide graphene oxide dispersion;

[0044] This step a specifically includes the following steps:

[0045] a1. Pour a strong acid such as concentrated sulfuric acid into the mixture of graphite flakes and sodium nitrate, and stir to obtain a dispersion; the mass ratio of graphite flakes to sodium nitrate is preferably 4:3.

[0046] a2. Slowly add a strong oxidant such as potassium permanganate to the a1 dispersion, stir for about 20h, and place it for 2-8 days, preferably 5 days; the mass ratio of graphite flakes to potassium permanganate is preferably 1:3-1: 5.

[0047] a3. Add deionized water and hydrogen peroxide in sequence to a2; the ratio of hydrogen peroxide to potassium permanganate is about 5:2.

[0048] a4. The graphene oxide dispersion is obtained after repeated centrifugal wash...

Embodiment 1

[0072] (1) Preparation of graphene oxide dispersion: weigh 5.0 grams of graphite flakes and 3.75 grams of NaNO 3 Put it in a 1-liter beaker, turn on the mechanical stirring, and slowly add 150 ml of concentrated sulfuric acid (98%); after stirring for half an hour, add 20 grams of KMnO 4 Add to the above dispersion within half an hour; continue to stir for about 20 hours, because the viscosity of the reactant increases, the electric stirrer fails, stop stirring; after standing for 5 days (during the period, the reactant is occasionally stirred manually), slowly add 500 ml of deionized Water (stir while adding), stir well and slowly add 30 ml H 2 o 2 , to generate a bright yellow suspension; centrifuge the suspension, pour off the supernatant, keep the lower layer of precipitate, then add water to disperse the precipitate, repeat this process three times, wash away the residual metal ions; then, add water to disperse the obtained precipitate, centrifuge , collect the upper la...

Embodiment 2

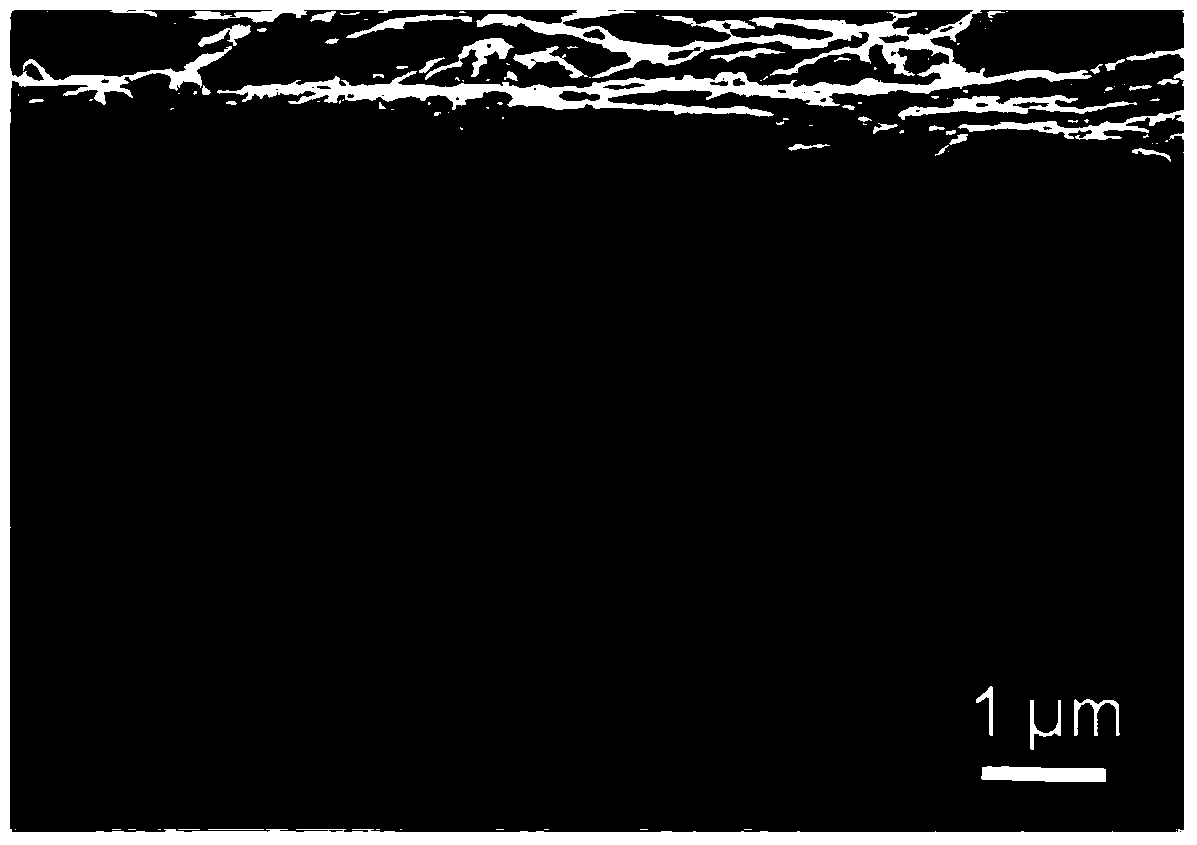

[0078] Repeat Example 1, with the following differences: when preparing the graphene oxide / carbon nanotube composite paper containing cobalt ions, add 0.1 milliliter of 1 mol / liter cobalt nitrate aqueous solution. The nitrogen-doped graphene / nitrogen-doped carbon nanotube / cobalt tetroxide composite paper was observed with a field emission scanning electron microscope, and the result was similar to Example 1. The ORR electrocatalytic performance test was carried out on the nitrogen-doped graphene / nitrogen-doped carbon nanotube / cobalt oxide composite paper, the starting potential was about -0.06V, and the current density at -0.9V was -4.22mAcm -2 . The results show that the ORR electrocatalytic performance of nitrogen-doped graphene / nitrogen-doped carbon nanotubes / cobalt tetroxide composite paper described in Example 2 is lower than that of nitrogen-doped graphene / nitrogen-doped carbon nanotubes / cobalt tetroxide described in Example 1 Composite paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com