Preparation method of superfine basic copper nitrate for gas generator

A gas generator and copper nitrate technology, applied in the direction of copper nitrate, etc., can solve the problems of crushing troubles, large power consumption, material loss, etc., and achieve the effects of reducing energy consumption and environmental pollution, saving equipment investment, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

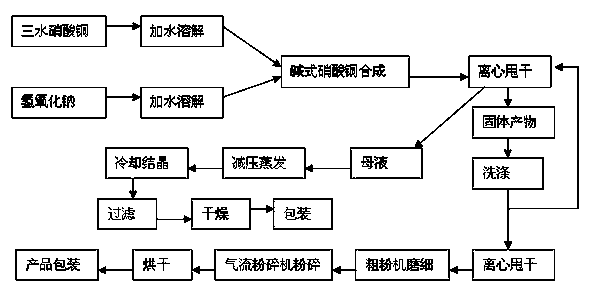

Method used

Image

Examples

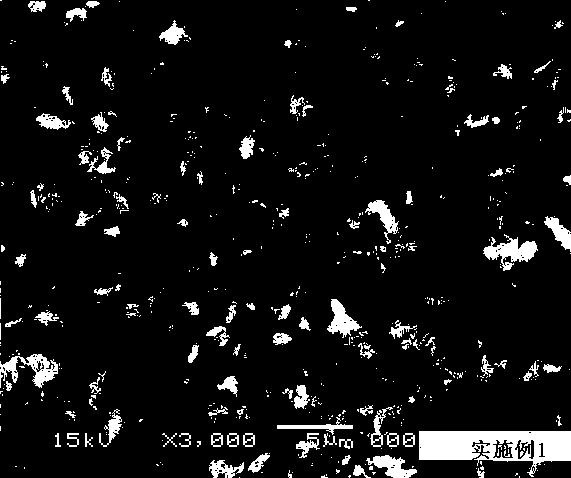

Embodiment 1

[0014] Copper nitrate trihydrate and sodium hydroxide, the raw materials for synthesis, were dissolved in deionized water respectively, and prepared into 3000L of 1mol / L solution and 1600L of 2.5mol / L solution respectively. Then 1600L of sodium hydroxide solution and 3kg of ultrafine polystyrene microspheres with a particle size of less than 0.5 μm are added to the reactor, and then the aqueous solution of the above-mentioned copper nitrate is gradually and uniformly added to the reactor within 0.5h, and the control The pH value of the reaction solution was 8.0, and the temperature was kept at about 70° C. for 0.5 h. After the reaction, the precipitate is filtered, the mother liquor is retained, the precipitate is added with water larger than the volume of the precipitate, and then the precipitated suspension is pumped into a spray dryer for spray drying and then packaged. The mother liquor is pumped into a reduced-pressure evaporator, and after being evaporated under reduced ...

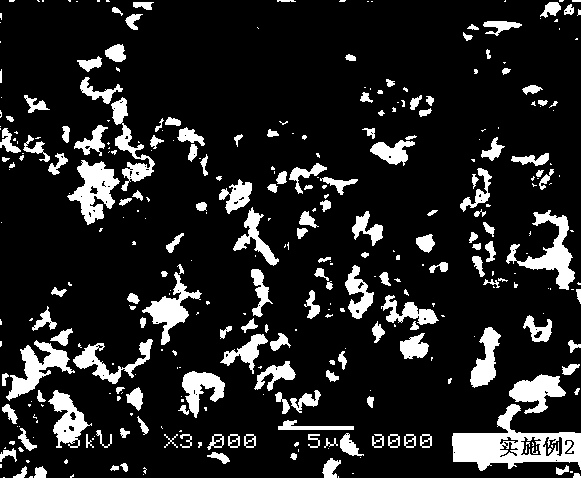

Embodiment 2

[0016] Copper nitrate trihydrate and sodium hydroxide, the raw materials for synthesis, were dissolved in deionized water, and prepared into 2220L of 1mol / L solution and 1500L of 2mol / L solution, respectively. Then 1500L of sodium hydroxide solution and 8 kg of fumed silica with a particle size of less than 0.5 μm were added to the reaction kettle, and then the above-mentioned copper nitrate aqueous solution was gradually and uniformly added to the reaction kettle within 0.5 hours to control the reaction liquid. The pH value is 8.5, keep the temperature at about 75°C, and react for 1 hour. After the reaction, the precipitate is filtered, the mother liquor is retained, the precipitate is added with water larger than the volume of the precipitate, and then the precipitated suspension is pumped into a spray dryer for spray drying and then packaged. The mother liquor is pumped into a reduced-pressure evaporator, and after being evaporated under reduced pressure, the solution is co...

Embodiment 3

[0018] Copper nitrate trihydrate and sodium hydroxide, the raw materials for synthesis, were dissolved in deionized water, respectively, and prepared into 1125L of 2mol / L solution and 1000L of 3mol / L solution, respectively. Then 1000L of sodium hydroxide solution and 31kg of precipitated silica with a particle size of less than 0.5μm were added to the reaction kettle, and then the above-mentioned copper nitrate aqueous solution was gradually and uniformly added to the reaction kettle within 0.5h to control the reaction liquid. The pH value is 9.0, keep the temperature at about 90°C, and react for 0.5h. After the reaction, the precipitate is filtered, the mother liquor is retained, the precipitate is added with water larger than the volume of the precipitate, and then the precipitated suspension is pumped into a spray dryer for spray drying and then packaged. The mother liquor is pumped into a reduced-pressure evaporator, and after being evaporated under reduced pressure, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com