Method for rapidly measuring content of furfural by high performance liquid chromatography

A high-performance liquid chromatography and rapid determination technology, which is applied in the field of rapid determination of furfural content by high-performance liquid chromatography, can solve the problems of toxicity, greater harm to laboratories and personnel, and short service life, so as to achieve accurate detection data and fast determination speed , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Sampling: From the furfural production workshop, connect the sampler to the sampling port, open the cooling water valve, and open the aldehyde vapor sampling valve after passing the cooling water. After the aldehyde vapor is condensed, it is collected in the sampling cup and discarded before 1 minute sample, collect 50ml of sample after 1 minute, for the determination of furfural content.

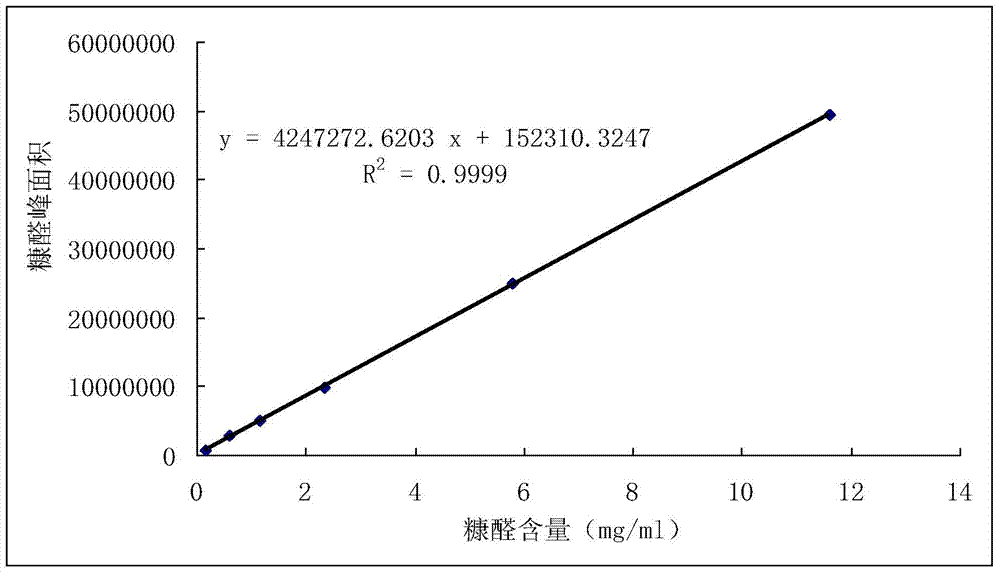

[0027] (2) Preparation of standard curve: According to the solubility of furfural in aqueous solution, draw 10, 50, 100, 200, 500, and 1000 μl of pure furfural solution into 100.0ml volumetric flasks respectively, add mobile phase to the mark, and shake well , to get the furfural standard series, respectively containing furfural 0.16, 0.58, 1.16, 2.32, 5.8, 11.6mg / ml; the standard curve regression equation obtained is

[0028] y=4247272.6203x+152310.3247

[0029] R 2 =0.9999

[0030] The correlation coefficient meets the requirements, and the standard curve is shown in the att...

Embodiment 2

[0040] (1) Sampling: From the furfural production workshop, connect the sampler to the sampling port, open the cooling water valve, and open the aldehyde vapor sampling valve after passing the cooling water. After the aldehyde vapor is condensed, it is collected in the sampling cup and discarded before 1 minute sample, collect 80ml of sample after 1 minute, for the determination of furfural content.

[0041] (2) Preparation of standard sample: According to the solubility of furfural in aqueous solution, draw 1000 μl of pure furfural solution into a 100.0ml volumetric flask, add mobile phase to the mark, and shake well to obtain a furfural standard sample of 11.6 mg / ml.

[0042] (3) Liquid phase system: chromatographic column: BIO RAD Aminex HPX-87H (300*7.8mm); mobile phase: 0.005mol sulfuric acid solution; flow rate: 0.600mL / min; column temperature: 60°C; differential detector temperature: 45 ℃;

[0043] (4) Sample treatment: Use a refractometer to measure the concentration ...

Embodiment 3

[0055] The difference from Example 2 is that the mobile phase used is a sulfuric acid solution of 0.01mol / L; the detection column temperature is 55°C, and the temperature of the differential detector is 40°C; the resulting standard sample peak area is 55241030, and the sample peak area is 41902863 , the sample concentration is

[0056] C=41902863×11.6×10÷55241030=87.9913 mg / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com