Production method for co-producing cement and sulfuric acid by using gypsum

A production method, cement raw material technology, applied in cement production, chemical instruments and methods, sulfur compounds, etc., can solve the problem of phosphogypsum morphology, specific surface reactivity differences, chlorine-based corrosion of sulfuric acid equipment, and different sources of phosphogypsum and other problems, to achieve the effect of eliminating environmental protection problems, easy control, and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

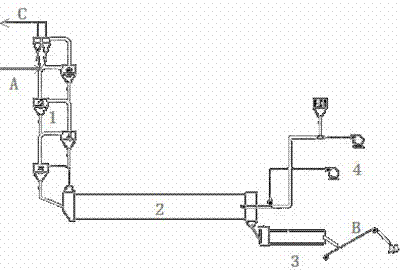

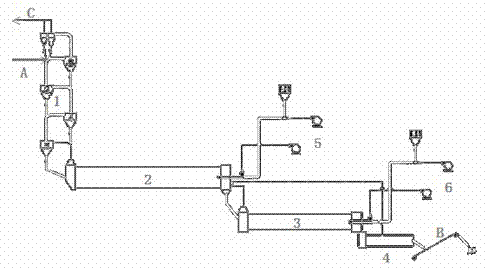

[0049] Such as figure 2 As shown, the phosphogypsum after drying and dehydration, reducing agent coke and other auxiliary materials after grinding are determined according to the quality requirements for the production of cement and co-production of sulfuric acid, and then the powder is mixed as gypsum cement raw material A (mainly Chemical Composition: SiO 2 8.68%, Fe 2 o 3 0.86%, Al 2 o 3 1.70%, CaO29.51%, MgO0.29%, SO 3 42.23%, P 2 o 5 0.61%, F - 0.10%, C3.78%). Then put 43,500 kilograms per hour into the multi-stage suspension preheater 1, and exchange heat with the 880°C decomposition hot gas coming out of the reduction and decomposition rotary kiln 2 through the multi-stage suspension preheater 1 to raise the temperature of the material to 760 ℃, and the gas temperature drops to 340 ℃ after heat exchange from the multi-stage suspension preheater 1. 85025Nm3 reduction and decomposition gas C is produced per hour, and its composition is shown in Table 1.

[0050...

Embodiment 2

[0056] Such as figure 2 As shown, the dry and dehydrated phosphogypsum, the reducing agent coke and other pulverized auxiliary materials are determined according to the quality requirements for the production of cement and co-production of sulfuric acid, and then the powder is mixed, and this is used as gypsum cement raw material A (mainly Chemical Composition: SiO 2 8.86%, Fe 2 o 3 0.88%, Al 2 o 3 1.80%, CaO30.15%, MgO0.23%, SO 3 43.13%, P 2 o 5 0.56%, F - 0.11%, C4.04%). Then put 87,000 kilograms per hour into the multi-stage suspension preheater 1, and exchange heat with the 850°C decomposition hot gas coming out of the reduction and decomposition rotary kiln 2 through the multi-stage suspension preheater 1 to raise the temperature of the material to 750 ℃, and the gas temperature drops to 340 ℃ after heat exchange from the multi-stage suspension preheater 1. Output 170051Nm per hour 3 Reduction and decomposition gas C, its composition is shown in Table 3.

[00...

Embodiment 3

[0063] Such as figure 2 As shown, the phosphogypsum after drying and dehydration, the reducing agent coke and other auxiliary materials after grinding are determined according to the quality requirements for the production of cement and sulfuric acid, and then the powder is mixed, which is used as gypsum cement raw material A (mainly Chemical Composition: SiO 2 8.92%, Fe 2 o 3 0.86%, Al 2 o 3 1.86%, CaO30.60%, MgO0.13%, SO 3 43.68%, P 2 o 5 0.56%, F - 0.11%, C4.14%). Then put 105,000 kilograms per hour into the multi-stage suspension preheater 1, and exchange heat with the 900°C decomposition heat gas coming out of the reduction and decomposition rotary kiln 2 through the multi-stage suspension preheater 1 to raise the temperature of the material to 780 °C, while the gas temperature drops to 330 °C after heat exchange from the multi-stage suspension preheater 1. Output 210415Nm per hour 3 Reduction decomposition gas C, its composition is shown in Table 5.

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com