High-strength, tear-resisting and antiflaming sheath rubber for cable and preparation method thereof

A sheath rubber, high-strength technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of low strength, reduced tensile strength, short service life, etc., and achieve high flame retardancy, high tensile strength and tear resistance cracking strength, avoiding the effect of performance deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

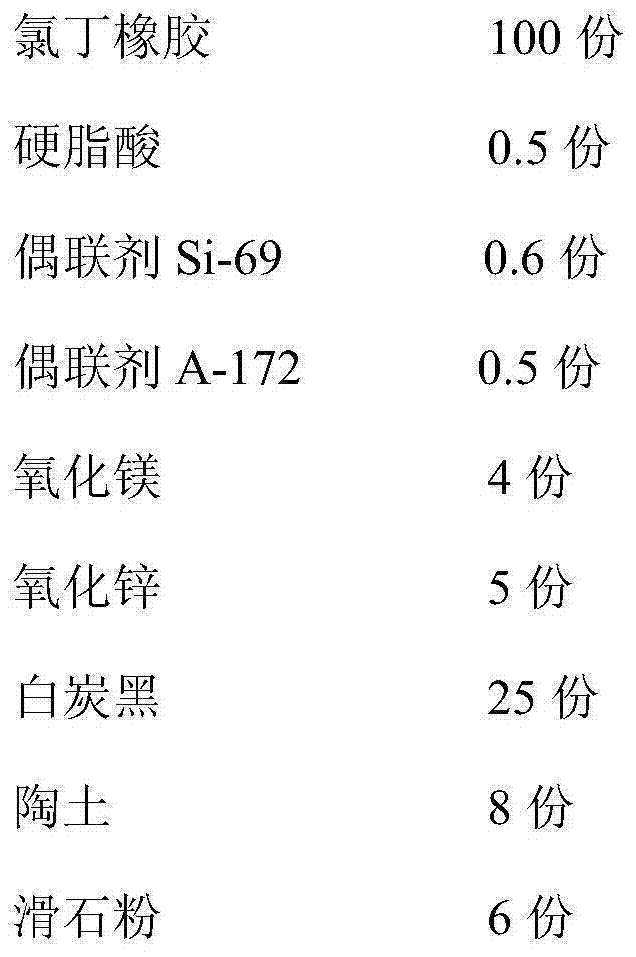

Embodiment 1

[0029]

[0030]

[0031] The chloroprene rubber is a non-sulfur-regulated rubber seed system; the antioxidant is a combination of quinoline antioxidant RD and diphenylamine antioxidant ODA; the coupling agent is a combination of Si-69 and A-172 .

[0032] Implementation process:

[0033] Mastication: After weighing the relevant materials according to the proportion, masticate the neoprene rubber at a temperature of 60-70°C for 5 minutes, and then place it at room temperature for more than 12 hours before performing subsequent mixing operations.

[0034] Mixing: Add stearic acid, 1 / 2 white carbon black, 1 / 2 pottery clay, 1 / 2 talcum powder and 1 / 2 plasticizer to the aforementioned masticate and mix evenly. After 2 minutes, add the remaining white carbon black. Mix carbon black, clay, talcum powder, plasticizer, coupling agent and flame retardant for 2 minutes, and finally add accelerator and zinc oxide and mix evenly. Material, the discharge temperature does not exceed 8...

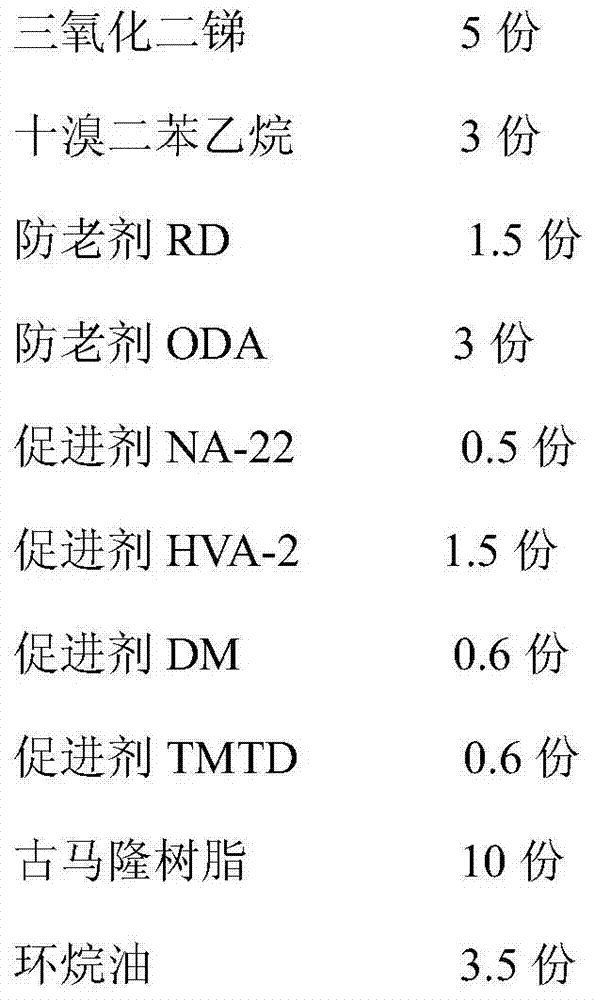

Embodiment 2

[0037]

[0038]

[0039] The chloroprene rubber is a non-sulfur-regulated rubber seed system; the antioxidant is a combination of quinoline antioxidant RD and diphenylamine antioxidant 4010; the coupling agent is a combination of Si-69 and A-172 .

[0040] Implementation process:

[0041] The difference between the implementation steps of this example and the implementation mode and Example 1 is that the coupling agent is first added to the white carbon black and clay for pre-dispersion during the mixing process, and after full absorption, 1 / 2 is added to the masticated chlorine Add 1 / 2 talcum powder and 1 / 2 plasticizer to butyl rubber (add anti-aging agent and magnesium oxide to chloroprene rubber for mastication and park for more than 12 hours), add 1 / 2 talcum powder, 1 / 2 plasticizer and mix evenly, add the rest of the white powder after about 2 minutes Carbon black, clay, talcum powder and flame retardant, finally add all the accelerators and zinc oxide and mix evenl...

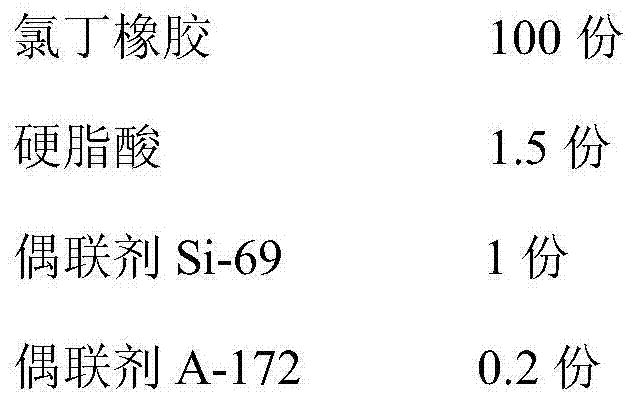

Embodiment 3

[0043]

[0044]

[0045] The chloroprene rubber is a sulfur-adjusted rubber; the anti-aging agent is a combination of quinoline anti-aging agent RD and diphenylamine anti-aging agent 4010; the zinc oxide is a combination of zinc oxide and other vulcanization aids.

[0046] Implementation process:

[0047] The difference between the implementation steps of this example and the implementation mode and Example 1 is that the coupling agent is first added to the white carbon black and clay for pre-dispersion during the mixing process, and after full absorption, 1 / 2 is added to the masticated chlorine Add 1 / 2 talcum powder and 1 / 2 plasticizer to butyl rubber (add anti-aging agent and magnesium oxide to chloroprene rubber for mastication and park for more than 12 hours), add 1 / 2 talcum powder, 1 / 2 plasticizer and mix evenly, add the rest of the white powder after about 2 minutes Carbon black, clay, talcum powder and flame retardant, finally add all the accelerators and zinc oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Mooney viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com