Application of Chryseobacterium sp. and carbonyl reductase thereof in production of aprepitant chiral intermediate

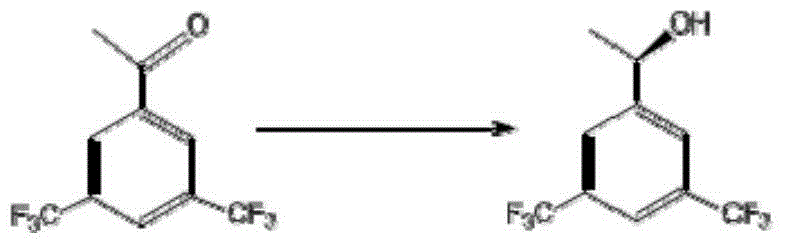

A kind of aureus, reductase technology, applied in the field of new carbonyl reductase, the production of aprepitant chiral intermediates, can solve the problem of low substrate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

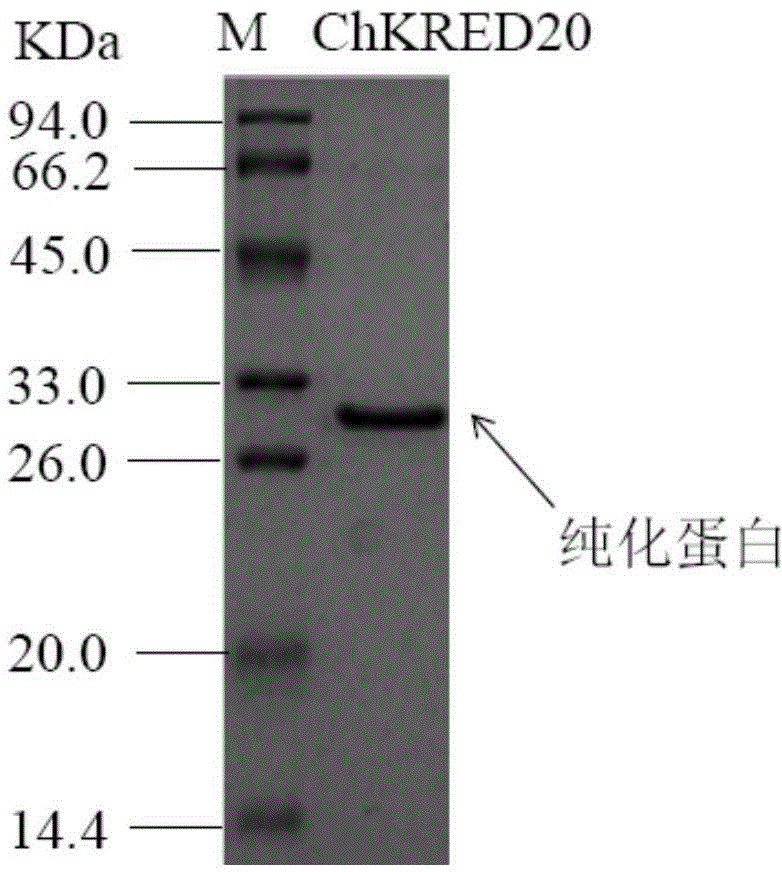

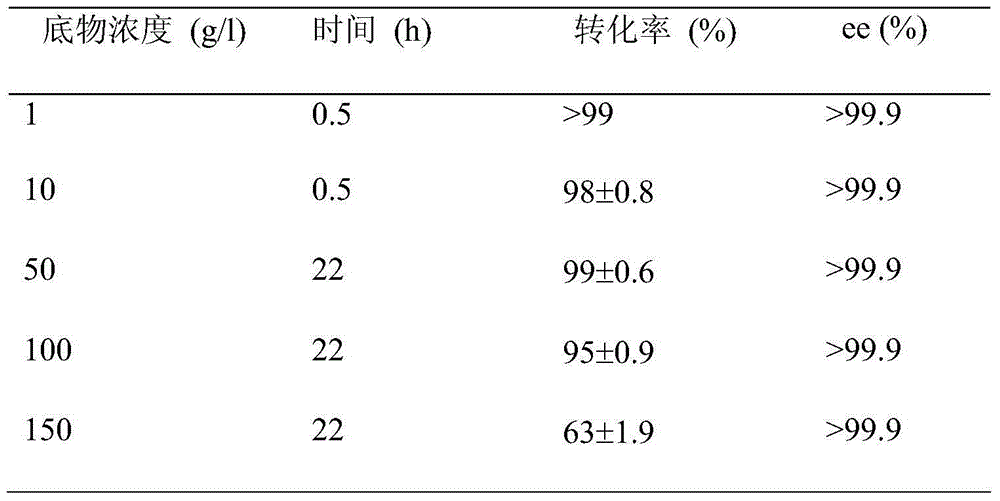

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: strain screening

[0038] Soil samples were collected in an orchard, and cultured at 30°C, 230rpm for 7-10 days with 3,5-bistrifluoromethylacetophenone (2g / L) as the sole carbon source and adding inorganic salts. The inorganic salt is: Na 2 HPO 4 2g / L, KH 2 PO 4 1g / L, NH 4 Cl0.4g / L, MgCl 2 0.4g / L. Take 1% of the enriched solution and add it to the same medium as above for further enrichment and culture for 7-10 days. The medium was then diluted 10 4 times, and spread on the screening plate (the above inorganic salt + 3,5-bistrifluoromethylacetophenone 1g / L + yeast powder 0.5g / L + agar powder 15g / L), culture at 30°C for 1-3 days, Many single colonies of microorganisms can be seen on each plate, and these strains are possible enzyme-producing strains.

[0039] The single colonies in the enrichment plate were inserted into each well of a 24-well screening plate (Costar, USA) one by one with a sterile toothpick for culture (each well was filled with 1...

Embodiment 2

[0040] Embodiment 2: the identification of screening bacterial strain

[0041] In order to confirm the taxonomic status of the strain and understand its performance in detail, the strain was initially identified. The colony of this strain is round and smooth, and with different culture time, the colony is light yellow to golden yellow.

[0042] 16S rRNA identification: Genomic DNA was used as a template, the 16S rRNA sequence was amplified with bacterial universal primers 27f and 1492r, and the PCR product was directly sent for sequencing. The obtained partial sequence (1381bp) was as follows (SEQ No.3):

[0043]AGCTGAGCGGTAGAGTTTCTTCGGAGACTTGAGAGCGGCGTACGGGTGCGGAACACGTGTGCAACCTGCCTTTATCAGGGGGATAGCCTTTCGAAAGGAAGATTAATACCCCATAATATATAGAGTGGCATCACTTTATATTGAAAACTGAGGTGGATAAAGATGGGCACGCGCAAGATTAGATAGTTGGTGAGGTAACGGCTCACCAAGTCGATGATCTTTAGGGGGCCTGAGAGGGTGATCCCCCACACTGGTACTGAGACACGGACCAGACTCCTACGGGAGGCAGCAGTGAGGAATATTGGACAATGGGTTAGCGCCTGATCCAGCCATCCCGCGTGAAGGACGACGGCCCTATGGGTTGTAAACTT...

Embodiment 3

[0045] Example 3: Biocatalysis of the original strain of Chryseobacterium sp.CA49

[0046] Strain cultivation: inoculate a small amount of slant seeds of Chryseobacterium sp.CA49 in the fermentation medium (the components are the same as in Example 1), culture at 30°C and 230rpm for 16-24 hours to prepare seed liquid, and use 0.5%-2% The inoculum amount is transferred to the fermentation medium for expanded cultivation, and the cultivation conditions are: 30°C, 230rpm, 24-48h.

[0047] Transformation of resting cells: The cells cultured in the first step were collected by centrifugation at 13,000 rpm, and washed twice with potassium phosphate buffer solution with a pH value of 7.0 and a concentration of 0.1M. The transformation system includes phosphate buffer (pH 7.0, 0.1M), bacteria, substrate and coenzyme cycle substrate. The coenzyme substrate is 5% to 10% (v / v) isopropanol and 2% to 5% (v / w) glucose. The cell concentration is 50-200g / L, the final substrate concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com