Method and system for flue gas demercuration by using desulfurization waste water of coal-fired power plant

A technology for desulfurizing wastewater and coal-fired power plants, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems such as the inability to reuse wastewater, negative system operation, and complicated configuration, so as to overcome high operating costs, The effect of saving operation cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

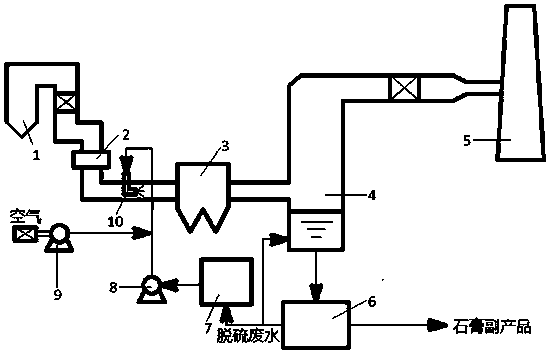

[0026] Such as figure 1 The shown system for flue gas demercury removal using desulfurization wastewater from coal-fired power plants includes air preheater 2, dust collector 3, absorption tower 4, dehydration device 6, desulfurization wastewater storage tank 7, water pump 8, air compressor 9 and Spraying device, wherein the air preheater 2, the dust collector 3 and the absorption tower 4 are connected sequentially through the flue, the flue gas inlet of the air preheater 2 is connected to the boiler 1, and the flue gas outlet of the absorption tower 4 is connected to the chimney 5. The water inlet of the dehydration device 6 is connected to the water outlet of the absorption tower 4 , and its water outlet is connected to the water inlet of the desulfurization wastewater storage tank 7 . A branch pipe communicating with the bottom of the absorption tower 4 is provided on the pipeline between the dehydration device 6 and the desulfurization wastewater storage tank 7 for returni...

Embodiment 2

[0028] Limestone-gypsum wet process by-products are produced by the dehydration device 6 and desulfurized wastewater without conventional neutralization, coagulation, flocculation, concentration and other conventional wastewater treatment is directly transported to the desulfurization wastewater storage tank 7, where halogen additives are added and mixed Uniformly form a desulfurization wastewater mixture, transport it to the flue before the entrance of the air preheater 2 and dust collector 3 through the water pump 8 through the wastewater pipeline, and then spray the desulfurization wastewater mixture evenly into the flue through the liquid atomizing nozzle 10, and mix with the flue gas In the desulfurization wastewater mixture, the mass ratio of the total mass of bromine and iodine elements in the halogen additive to the chlorine element in the desulfurization wastewater is 0.05, and the injection amount is 0.003L / m 3 smoke. After testing, the Hg content at the outlet of th...

Embodiment 3

[0031] Limestone-gypsum wet process by-products are produced by the dehydration device 6 and desulfurized wastewater without conventional neutralization, coagulation, flocculation, concentration and other conventional wastewater treatment is directly transported to the desulfurization wastewater storage tank 7, where mercury removal catalyst is added and Mix evenly to form a mixture of desulfurization wastewater, and use the water pump 8 to transport it to the flue before the entrance of the air preheater 2 and dust collector 3 through the wastewater pipeline, and then spray the desulfurization wastewater mixture evenly into the flue through the liquid atomizing nozzle 10, and mix with the flue gas In the desulfurization wastewater mixture, the mass ratio of the total mass of iron ions and manganese ions in the mercury removal catalyst to the chlorine element in the desulfurization wastewater is 0.01, and the injection volume is 0.004L / m 3 smoke. After testing, the Hg content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com