Quaternary ammonium salt group-containing halide amine polymer antibacterial agent, and preparation method and application thereof

A quaternary ammonium salt group and polymer technology, which is applied in the field of halamine antibacterial agent synthesis, can solve the problems of poor water solubility of synthetic intermediate/final products, high synthesis reaction temperature, and expensive synthetic raw materials, etc., and achieves superior antibacterial performance, reaction The effect of short time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

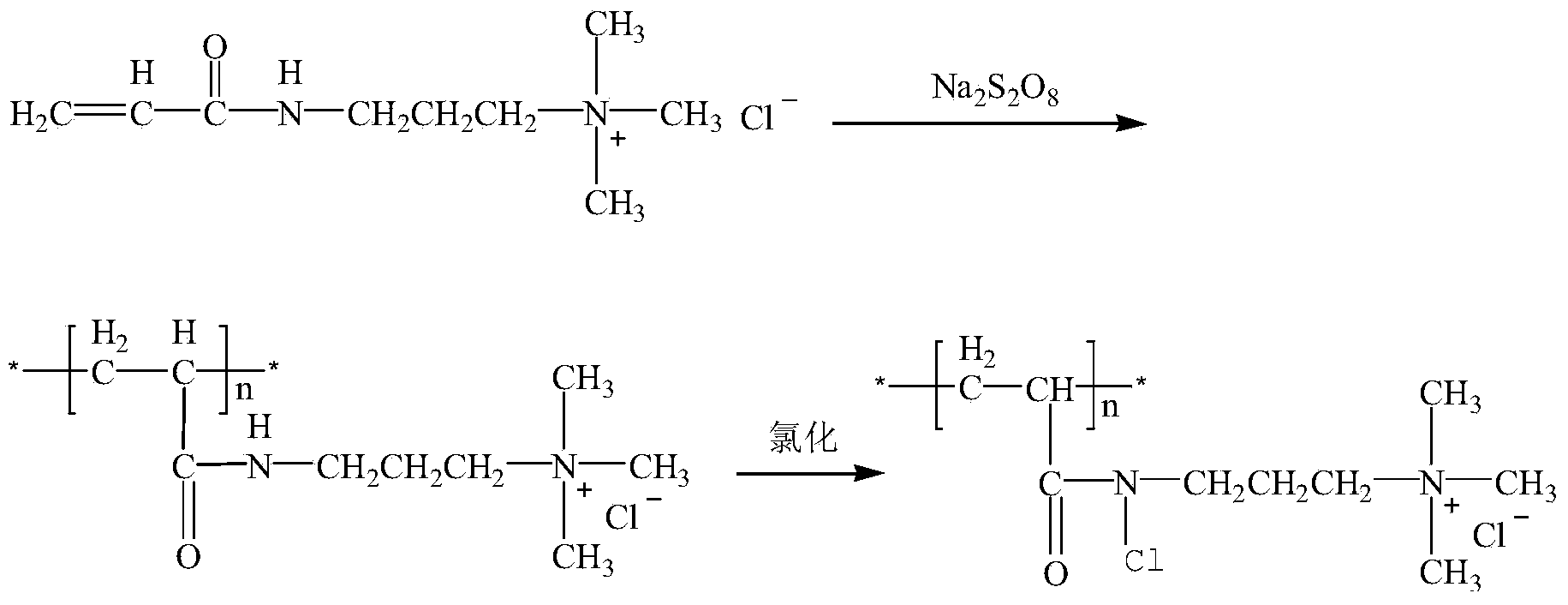

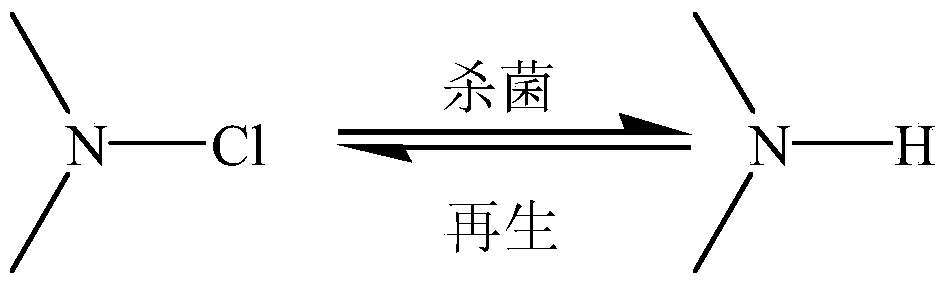

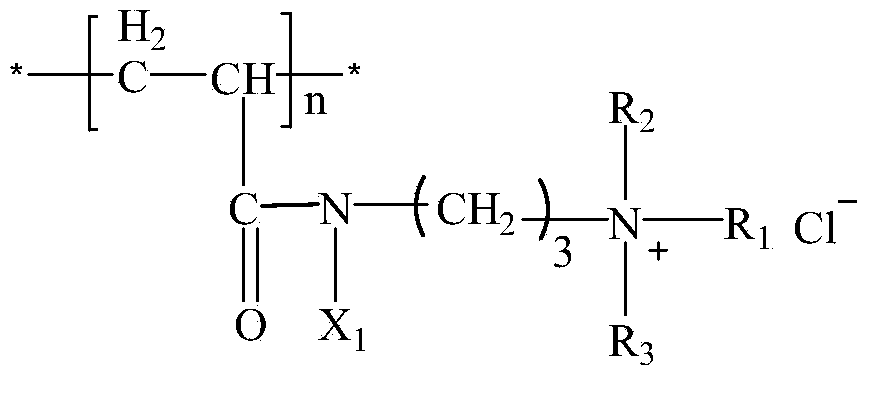

Method used

Image

Examples

Embodiment 1

[0038] Weigh 27.56g of 70-80% 3-acrylamidopropyltrimethylammonium chloride into a three-necked flask, add 150mL of water, then add 0.12g of sodium persulfate, and pass nitrogen gas for 30min, then heat up to 80°C, and react 8h; after the reaction, the water in the product solution was removed by distillation under reduced pressure, and the obtained solute was purified with ethanol, and the obtained product was dried in a vacuum drying oven at 60°C and 0.2MPa for 12h to obtain the haloamine compound Precursor poly 3-acrylamidopropyltrimethylammonium chloride; dissolve the precursor in a sodium hypochlorite solution with a concentration of 1% by mass, and leave it to react at room temperature for 1 hour. After the reaction is completed, proceed according to the conventional operation method Filtrate and dry to obtain the finished product poly-3-acryloyl chloride propyl trimethyl ammonium chloride of haloamine polymer antibacterial agent.

Embodiment 2

[0040] Weigh 27.56g of 70-80% 3-acrylamidopropyltrimethylammonium chloride into a three-necked flask, add 150mL of water, then add 0.12g of sodium persulfate, and pass through nitrogen for 30min, then heat up to 60°C, and react 12h; After the reaction, the water in the product solution was removed by distillation under reduced pressure, and the obtained solute was purified with ethanol, and the obtained product was dried in a vacuum oven at 60°C and 0.2MPa for 12h to obtain the haloamine compound Precursor poly 3-acrylamidopropyltrimethylammonium chloride; dissolve the precursor in a sodium hypochlorite solution with a concentration of 5% by mass, and leave it to react at room temperature for 1 hour. After the reaction is completed, proceed according to the conventional operation method Filtrate and dry to obtain the finished product 3-acryloyl chloride propyl trimethyl ammonium chloride of the haloamine polymer antibacterial agent.

[0041] Application Examples of Halamine Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com