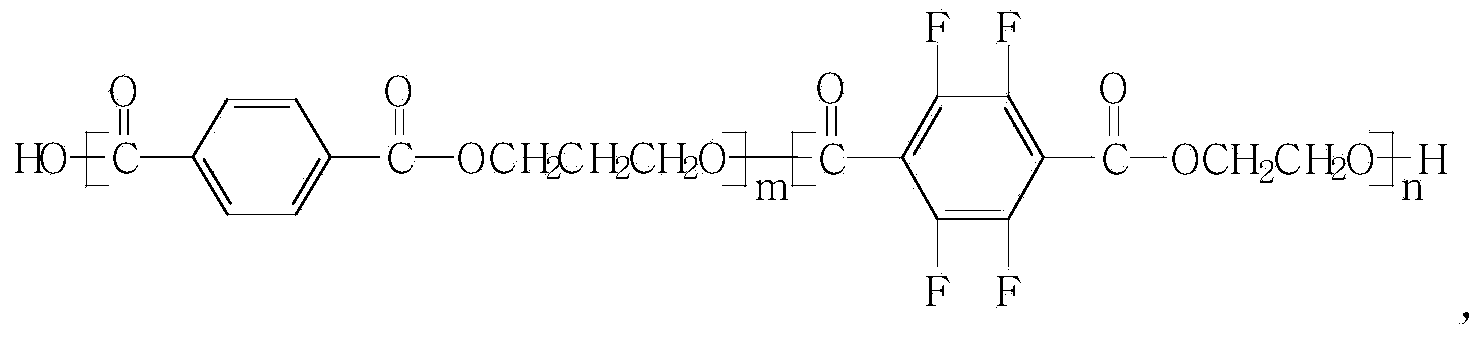

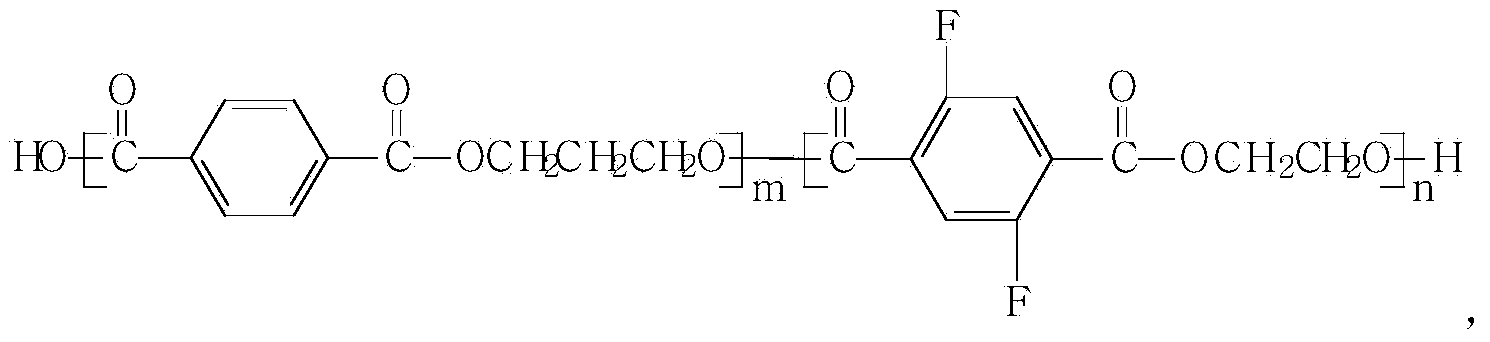

Fluorine-containing PET (polyethylene terephthalate)-PTT (polytrimethylene terephthalate) copolyester FDY (fully drawn yarn) fiber and preparation method thereof

A PET-PTT, fluorine-containing polyester technology, applied in the direction of single-component copolyester rayon, fiber type, fiber processing, etc., can solve the problem of time-consuming and laborious, achieve smooth and soft hand feel, solve the problem of timeliness, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

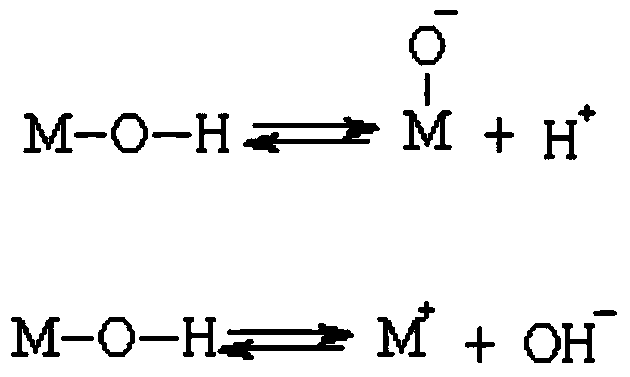

[0071] A preparation method of fluorine-containing PET-PTT copolyester is divided into an esterification reaction stage, a precondensation reaction stage and a final polycondensation reaction stage. The specific steps are:

[0072] Step 1): Use tetrafluoroterephthalic acid and ethylene glycol with a molar ratio of 1:1.3 as raw materials, and add 0.01% magnesium oxide based on the weight of tetrafluoroterephthalic acid at the same time, make a uniform slurry and carry out esterification Reaction; the esterification reaction is pressurized in a nitrogen atmosphere, the pressure is controlled at 0.4MPa, and the temperature is at 250°C. The esterification water distillate reaches more than 90% of the theoretical value, which is the end of the esterification reaction; add the catalyst antimony trioxide and continue Vacuumize the system, control the pressure of the system below the absolute pressure of 1KPa, and control the temperature at 260°C to carry out the pre-condensation reac...

Embodiment 2

[0078] A preparation method of fluorine-containing PET-PTT copolyester is divided into an esterification reaction stage, a precondensation reaction stage and a final polycondensation reaction stage. The specific steps are:

[0079] Step 1): 2,5-difluoroterephthalic acid and ethylene glycol with a molar ratio of 1:1.5 are used as raw materials, and 0.03% of the weight of 2,5-difluoroterephthalic acid is added at the same time. After forming a uniform slurry, carry out the esterification reaction; the esterification reaction is pressurized in a nitrogen atmosphere, the pressure is controlled at 0.3MPa, the temperature is at 245°C, and the esterification water distillate reaches more than 90% of the theoretical value, which is the end point of the esterification reaction; Add the antimony ethylene glycol catalyst, continue vacuuming, control the system pressure below 800Pa absolute pressure, control the temperature at 260°C, carry out pre-condensation reaction, react for 2 hours,...

Embodiment 3

[0085] A preparation method of fluorine-containing PET-PTT copolyester is divided into an esterification reaction stage, a precondensation reaction stage and a final polycondensation reaction stage. The specific steps are:

[0086] Step 1): Use tetrafluoroterephthalic acid and ethylene glycol with a molar ratio of 1:1.8 as raw materials, and add 0.05% calcium oxide based on the weight of tetrafluoroterephthalic acid at the same time, make a uniform slurry and carry out esterification Reaction: The esterification reaction is pressurized in a nitrogen atmosphere, the pressure is controlled at 0.2MPa, the temperature is 240°C, and the amount of esterified water distilled reaches more than 90% of the theoretical value, which is the end of the esterification reaction; the catalyst antimony acetate is added, and the vacuum is continued , the system pressure is controlled below the absolute pressure of 600Pa, the temperature is controlled at 265°C, and the precondensation reaction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com