Preparation method of low surface pore and low dielectric constant thin-film material

A low-dielectric constant, thin-film material technology, applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., to achieve the effects of small bombardment, good continuity, and reduced pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of low surface porosity low dielectric constant film material of the present invention, it comprises the steps:

[0032] (1) Provide a silicon substrate, clean it, and place the cleaned silicon substrate in an electron cyclotron resonance plasma device. Preferably, the aforementioned silicon substrate is a (100)-oriented n-type silicon substrate. And the above cleaning method is standard cleaning.

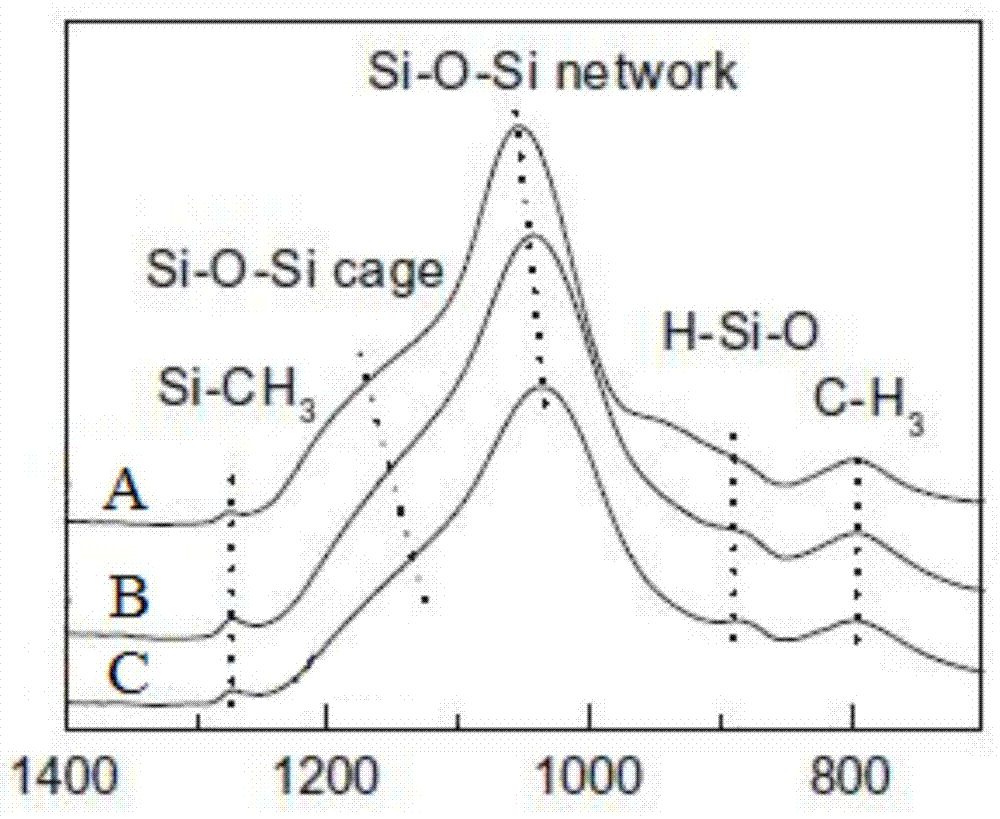

[0033] (2) Place the D5 ring silicone in a constant temperature evaporator, and use the inert gas as the carrier gas to transport the vaporized D5 ring silicone to the electron cyclotron resonance plasma device through the transmission pipeline. Among them, the D5 ring silicone is a single ring structure consisting of five Si-O bonds and ten methyl groups. The constant temperature in the above-mentioned constant temperature evaporator is preferably 80°C, and at the same time, in order to prevent the vaporized D5 ring silicone from being liquefi...

Embodiment 1

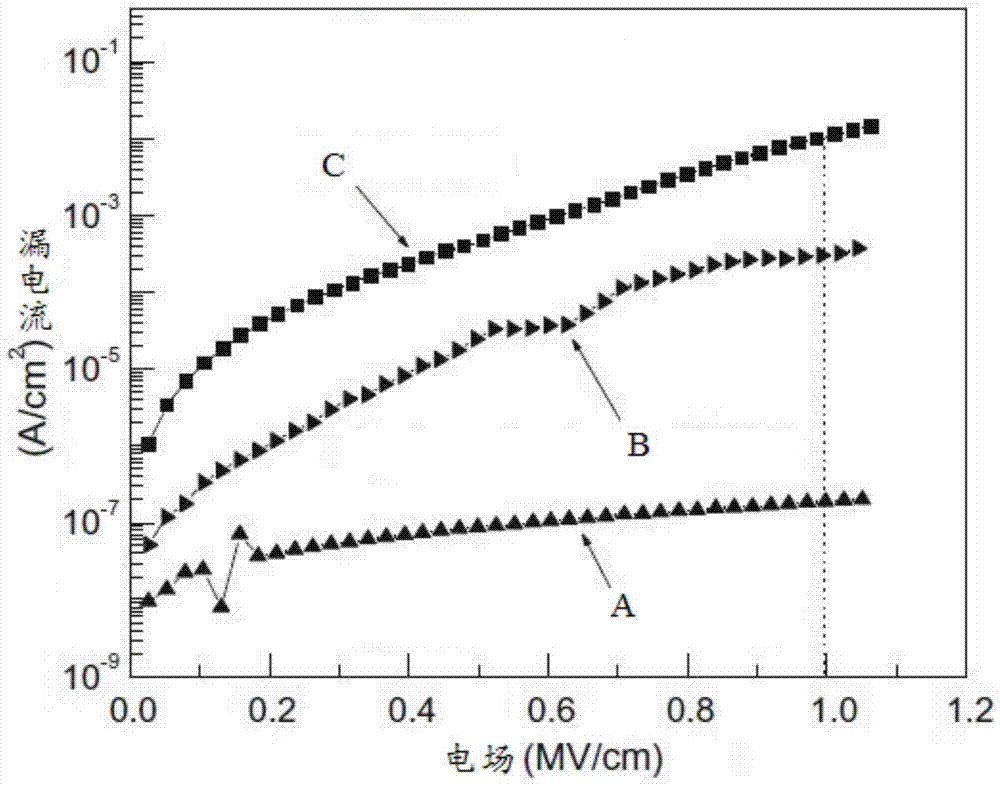

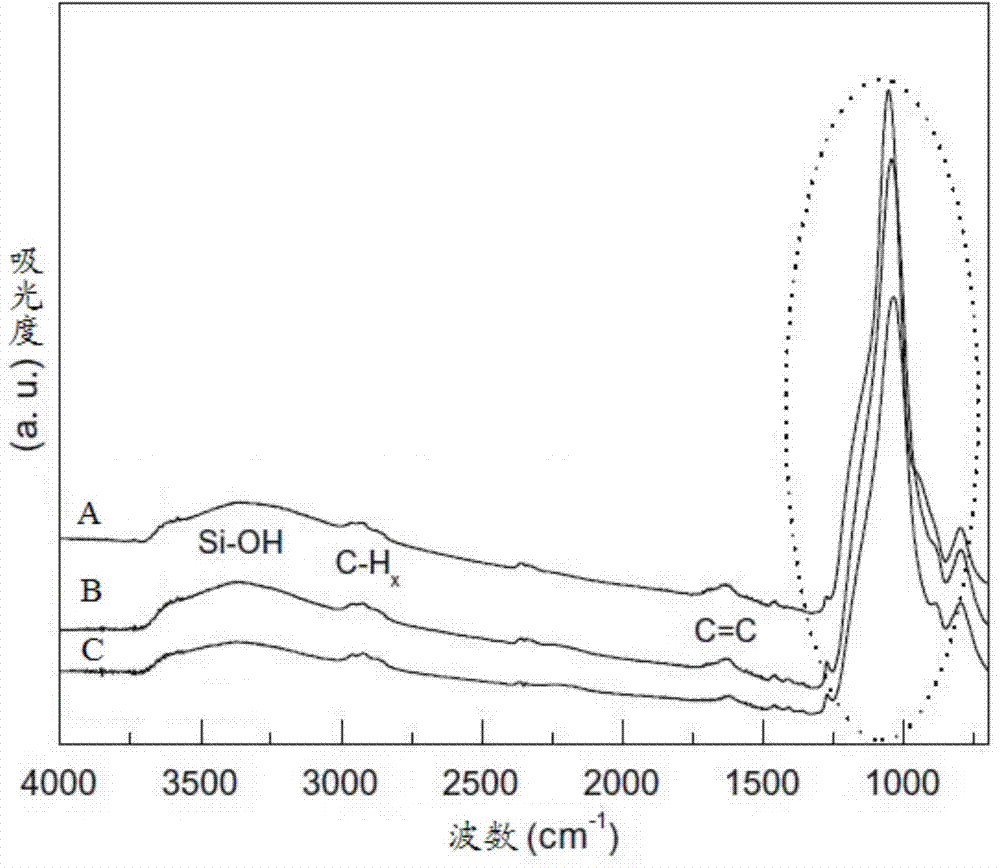

[0041] Provide a low-resistance single crystal silicon substrate, perform standard clearing on it, and place it in an electron cyclotron resonance plasma device. D5 ring silicone with a purity of 98% was prepared as a precursor, and the D5 ring silicone was placed in a constant temperature evaporator at 80 °C to vaporize it. Using argon as a carrier gas, the vaporized D5 ring organosilicon was sent into the cavity of the electron cyclotron resonance plasma equipment through a transmission pipeline at 80 °C, and the flow ratio of the vaporized D5 ring organosilicon and argon was kept at 6. :1, the total gas flow rate is controlled at 15 sccm. Controlling the current I of two coils in an electron cyclotron resonance plasma device 1 and I 2 They are 150A and 110A respectively, the microwave incident power is 300W, and the reflected power is 2%. The D5 ring organic silicon forms a plasma and decomposes, and deposits a SiCOH film on a silicon substrate under the action of a magn...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is that the microwave incident power is controlled to be 800 W when oxygen is introduced, and the other steps are the same as those of embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com