Process for recycling wastewater containing low boiling-point organism such as formaldehyde and high-concentration inorganic salt

A technology of organic matter and inorganic salt, which is applied in the field of recycling technology and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

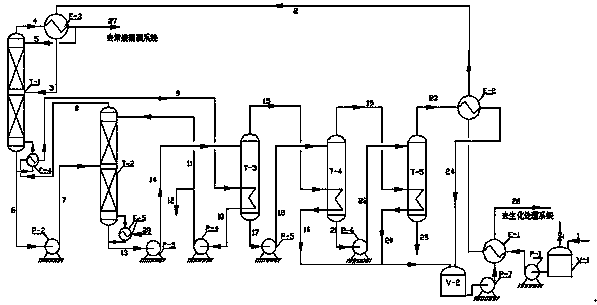

[0022] The technological process of recycling waste water containing formaldehyde and other low-boiling point organic substances and high-concentration inorganic salts produced in the flavor and fragrance industry is shown in the attachment figure 1 shown. The system is mainly composed of rectification system and multi-effect evaporation system. There are metering and control instruments and pipelines between each equipment. The waste water containing 0.01% low-boiling point organic mixture (including formaldehyde, methanol, chloromethane, etc.) and 10% inorganic salts enters the neutralization tank V-1 from pipeline 1 for alkali neutralization, and the solution becomes neutral. After that, preheat three times through heat exchangers E-1, E-2 and E-3. The heat source of heat exchanger A E-1 is the mixed solution in intermediate tank V-2, and the heat source of heat exchanger B E-2 is The steam at the top of the third-stage evaporator T-5, and the heat source of E-3 is the st...

Embodiment 2

[0027] The mode of operation is as in Example 1.

[0028] Wastewater containing 4.2% low-boiling organic mixtures (including formaldehyde, methanol, ethanol, chloromethane, etc.) and 23% inorganic salts produced in the pharmaceutical industry enters the neutralization storage tank V-1 through pipeline 1 for alkali neutralization And, the solution becomes neutral, and then preheated three times through heat exchangers A, B and C E-1, E-2 and E-3, and the heat source of heat exchanger A E-1 is intermediate tank V-2 The mixed solution in the heat exchanger B E-2 heat source is the steam at the top of the third pole evaporator T-5, and the heat source of heat exchanger C E-3 is the steam at the top of the atmospheric distillation column T-1. The raw material that has been preheated three times enters the atmospheric rectification tower T-1 through the pipeline 33, and the steam at the top of the atmospheric distillation tower T-1 passes through the heat exchanger C E-3 to preheat ...

Embodiment 3

[0033] The mode of operation is as in Example 1.

[0034] Wastewater containing 10% low-boiling point organic compounds (including formaldehyde, methanol, methylene chloride, etc.) and 40% inorganic salts produced in the leather industry enters the neutralization storage tank V-1 through pipeline 1 for alkali neutralization, Turn the solution into neutral, then preheat three times through heat exchangers A, B and C E-1, E-2 and E-3, the heat source of heat exchanger A E-1 is the intermediate tank V-2 For the mixed solution, the heat source of heat exchanger B E-2 is the steam at the top of the third-stage evaporator T-5, and the heat source of heat exchanger C E-3 is the steam at the top of the atmospheric distillation tower T-1. The raw material that has been preheated three times enters the atmospheric rectification tower T-1 through the pipeline 33, and the steam at the top of the atmospheric distillation tower T-1 passes through the heat exchanger C E-3 to preheat and cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com