Full-temperature range pressure swing adsorption purification method for simultaneously removing water and hydrocarbon from natural gas

A pressure swing adsorption and natural gas technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve problems such as incomplete regeneration, bed destruction, easy adsorption and desorption, etc., to improve stability and safety, solve Adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

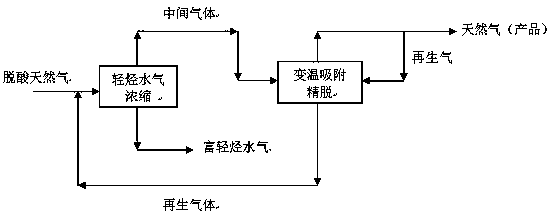

[0039] Such as figure 1 Shown, a kind of full-temperature pressure swing adsorption purification method of simultaneously dehydrating and dehydrocarbonizing natural gas, the steps of this method are as follows:

[0040] (1) Concentration process of light hydrocarbon water gas: natural gas at a temperature of 50~80°C and a pressure of 5.0~7.0MPa, after pretreatment to remove acid components, its composition is methane 92.18% (volume ratio, the following types same), ethane 3.33%, propane 1.48%, butane 0.79%, pentane 0.25%, C 6 + 0.05%, water dew point 5~20℃, total sulfur ≤30mg / m 3 , CO 2 ≤10ppmv, 0.73% nitrogen, directly enter the light hydrocarbon water vapor concentration process through the intake pipe, adopt the pressure swing adsorption (PSA) process of 10 towers in series and parallel, the operating temperature is 50~80°C, and the operating pressure is 5.0~7.0MPa Adsorption is carried out under certain conditions, 3 towers for adsorption, 7 towers for regeneration, an...

Embodiment 2

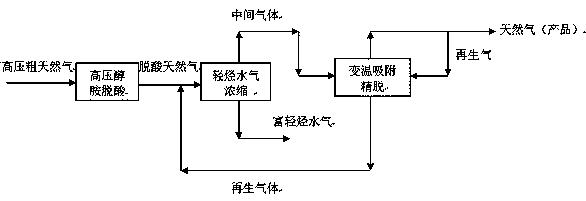

[0045] Such as figure 2 As shown, further optimization is carried out on the basis of a full-temperature pressure swing adsorption purification method for simultaneous dehydration and dehydrocarbonation of natural gas described in Example 1. The natural gas is pretreated to remove acidic components, and the high-pressure alcohol amine method is used. (MDEA: methyldiethanolamine) removes acid gas components from the high-pressure crude natural gas from the wellhead, so that the total sulfur in the net natural gas is less than or equal to 30mg / m 3 , CO 2 ≤10ppmv, as the natural gas raw material gas entering this embodiment.

Embodiment 3

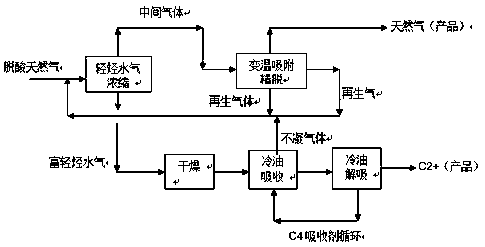

[0047] Such as image 3 As shown, on the basis of a full-temperature pressure swing adsorption purification method for simultaneous dehydration and dehydrocarbonation of natural gas described in Example 1, further optimization, the light hydrocarbon water gas in the light hydrocarbon water gas concentration process is pressurized to 5.0~7.0MPa, sent to the drying system to further remove the concentrated water, and then enter the cold oil absorption method to recover C2+ process, the absorbent is C4 (mixture of n-butane and isobutane), the temperature is 50~80℃, The non-condensable gas mainly composed of methane escapes from the top of the absorption tower, or is directly used as the regeneration gas in the temperature swing adsorption fine extraction process after heating, so as to reduce the use of product natural gas as regeneration gas, and the yield of natural gas products can reach more than 95%; or with The natural gas raw material is mixed into the light hydrocarbon wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com