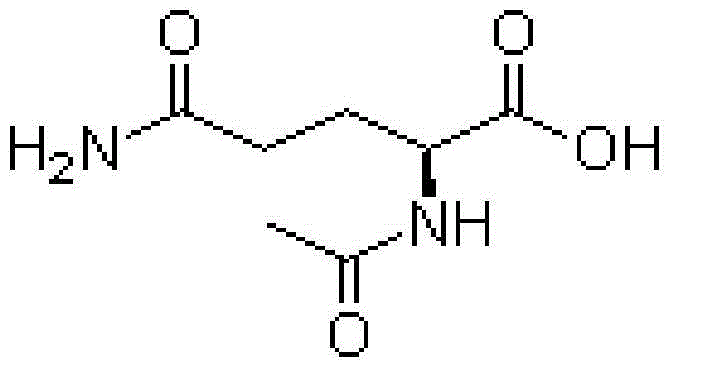

Aceglutamide composition freeze-dried powder injection for injection

A technology of acetylglutamine and freeze-dried powder injection, which is applied in the direction of freeze-dried delivery, drug combination, powder delivery, etc., to improve the ability of the central nervous system, good resolubility, and enhance the effect of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of acetylglutamine composition freeze-dried powder for injection (specification: 100 mg, calculated as acetylglutamine), in 1000 vials.

[0035] 1. Prescription:

[0036] Acetyl Glutamine 100g

[0037] Chitosan Nanoparticles 200g

[0038] Water for injection 2000ml

[0039] 2. Preparation process:

[0040] 1) Weigh 200g of chitosan nanoparticles and slowly add to 2000ml of water for injection (while adding, stir until dissolved.

[0041] 2) Continue to add 100g of acetylglutamine and stir to dissolve until clear.

[0042] 3) Use sodium hydroxide to adjust the pH to 5.5-6.0, add activated carbon with 0.1% volume of water for injection and stir for 30 minutes; then decarburize and circulate and filter through titanium rods for 30 minutes; then sterilize through 0.45 μm and 0.22 μm Circulate filtration for 30 minutes; detect the content of intermediates, and calculate the filling amount of 100 mg per bottle based on acetylglutamine.

[0043] 4) Fill accor...

Embodiment 2

[0045] Preparation of acetylglutamine composition freeze-dried powder for injection (specification: 100 mg, calculated as acetylglutamine), in 1000 vials.

[0046] 1. Prescription:

[0047] Acetyl Glutamine 100g

[0048] Chitosan Nanoparticles 160g

[0049] Water for injection 2000ml

[0050] 2. Preparation process:

[0051] 1) Weigh 160g of chitosan nanoparticles and slowly add to 2000ml of water for injection, stir until dissolved while adding.

[0052] 2) Continue to add 100g of acetylglutamine and stir to dissolve until clear.

[0053]3) Adjust the pH to 5.5-6.0 with sodium hydroxide, add activated carbon with 0.1% volume of water for injection and stir for 30 minutes; then decarburize and circulate and filter through titanium rods for 30 minutes; then sterilize by 0.45 μm and 0.22 μm Circulate filtration for 30 minutes; detect the content of intermediates, and calculate the filling amount of 100 mg per bottle based on acetylglutamine.

[0054] 4) Fill according to t...

Embodiment 3

[0056] Preparation of acetylglutamine composition freeze-dried powder for injection (specification: 100 mg, calculated as acetylglutamine), in 1000 vials.

[0057] 1. Prescription:

[0058] Acetyl Glutamine 100g

[0059] Chitosan Nanoparticles 250g

[0060] Water for injection 2000ml

[0061] 2. Preparation process:

[0062] 1) Weigh 250g of chitosan nanoparticles and slowly add to 2000ml of water for injection, stir until dissolved while adding.

[0063] 2) Continue to add 100g of acetylglutamine and stir to dissolve until clear.

[0064] 3) Adjust the pH to 5.5-6.0 with sodium hydroxide, add activated carbon with 0.1% volume of water for injection and stir for 30 minutes; then decarburize and circulate and filter through titanium rods for 30 minutes; then sterilize by 0.45 μm and 0.22 μm Circulate filtration for 30 minutes; detect the content of intermediates, and calculate the filling amount of 100 mg per bottle based on acetylglutamine.

[0065] 4) Fill according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com