Pt/MOx catalyst and application thereof in toluene catalytic combustion

A technology of catalysts and oxides, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve problems such as cumbersome operations, environmental pollution, and strict requirements for the preparation process, and achieve good stability, high activity, and low environmental costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Pt / MO x Catalyst preparation

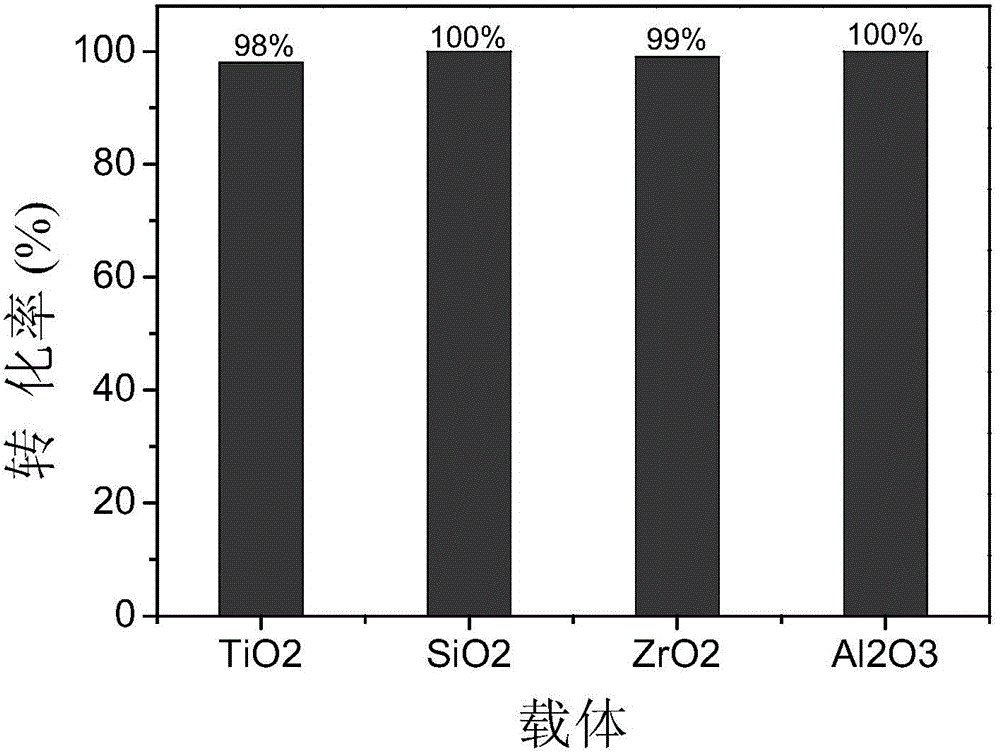

[0029] The precursor 34mg Pt 2 (dba) 3 Add 100ml of propylene carbonate, and react in a stainless steel reactor at 3.0MPa and room temperature (20°C) for 2 hours to obtain the reaction solution, namely 100ml of Pt nanoparticle solution; the carrier MO x (MO x = TiO 2 , SiO 2 , ZrO 2 、Al 2 o 3 ) was added to the obtained Pt nanoparticle solution, stirred overnight under electric stirring, filtered, and the filter cake was washed with acetone several times and then dried to obtain 1% Pt / MO x catalyst.

Embodiment 2

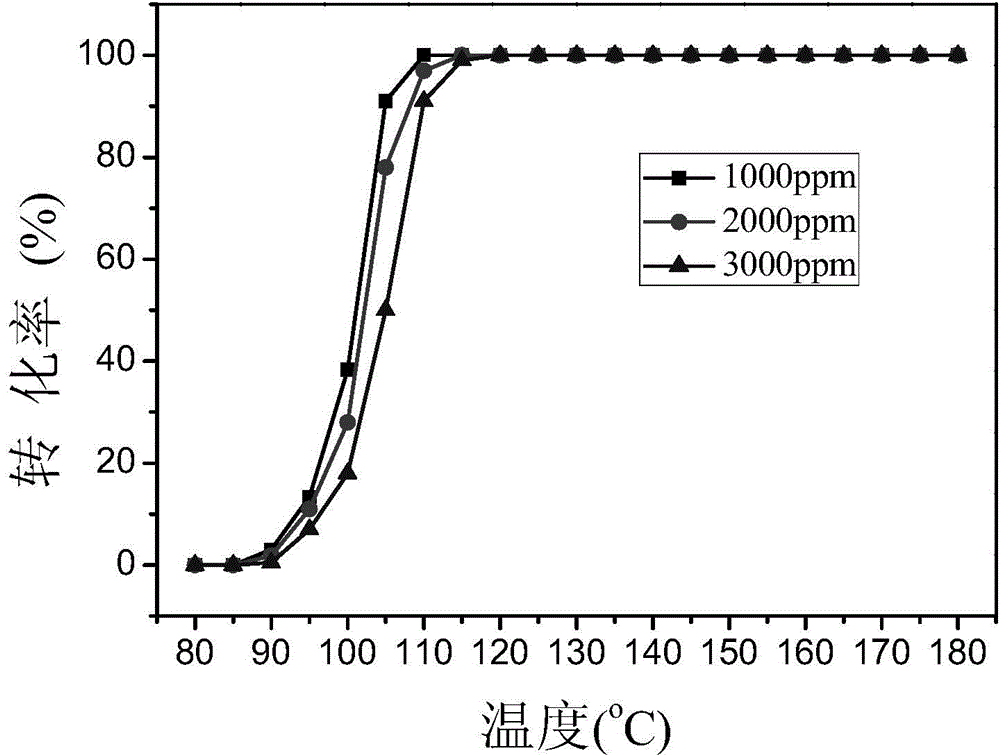

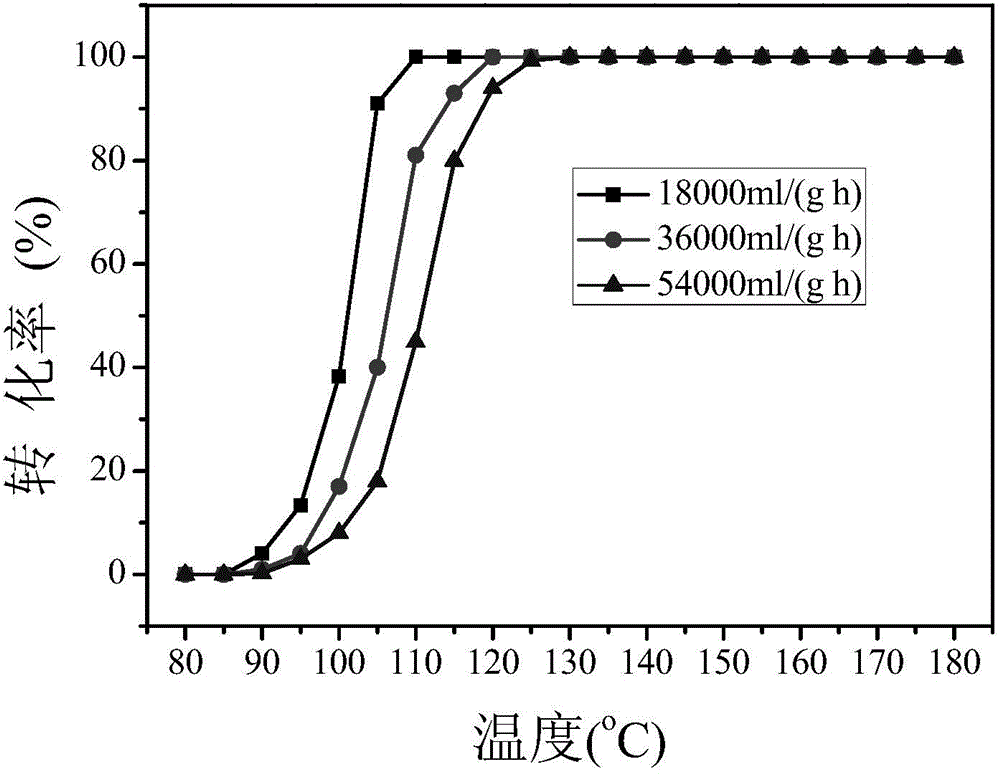

[0031] Weigh 0.5g Pt / TiO 2 The catalyst is placed in a quartz tube reactor with an inner diameter of 8mm, the gas flow rate is adjusted so that the concentration of toluene is 1000ppm, the reaction space velocity (GHSV) is 18000ml / (g h), and the reaction temperature range is from 80°C to 180°C. Toluene concentration and products were determined by gas chromatography.

[0032] The reaction results show that the conversion rate of toluene reaches 98% after passing through the catalyst system at 110°C.

[0033] Pt / TiO 2 Catalyst activity evaluation results are attached figure 1 .

Embodiment 3

[0035] Weigh 0.5g Pt / SiO 2 The catalyst is placed in a quartz tube reactor with an inner diameter of 8mm, the gas flow rate is adjusted so that the concentration of toluene is 1000ppm, the reaction space velocity (GHSV) is 18000ml / (g h), and the reaction temperature range is from 80°C to 180°C. Toluene concentration and products were determined by gas chromatography.

[0036] The reaction results show that the conversion rate of toluene reaches 100% after passing through the catalyst system at 110°C.

[0037] Pt / SiO 2 Catalyst activity evaluation results are attached figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com