A Schiff base nickel complex and its application as a pickling corrosion inhibitor for metal materials

A technology of Schiff base nickel and metal materials, applied in the direction of nickel organic compounds, etc., to achieve the effect of good corrosion inhibition efficiency, expanded application range, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

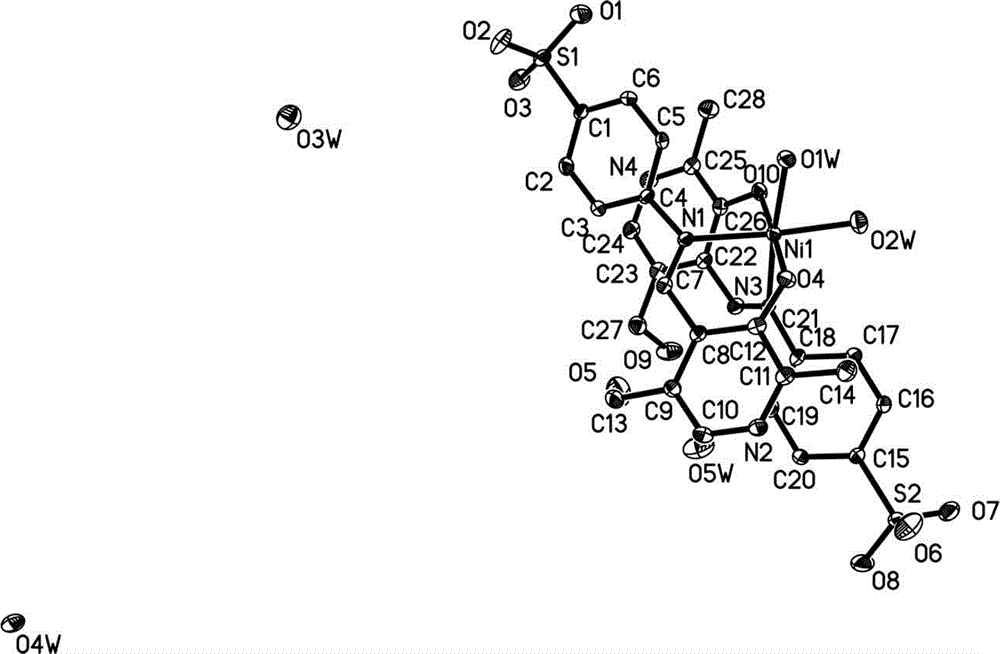

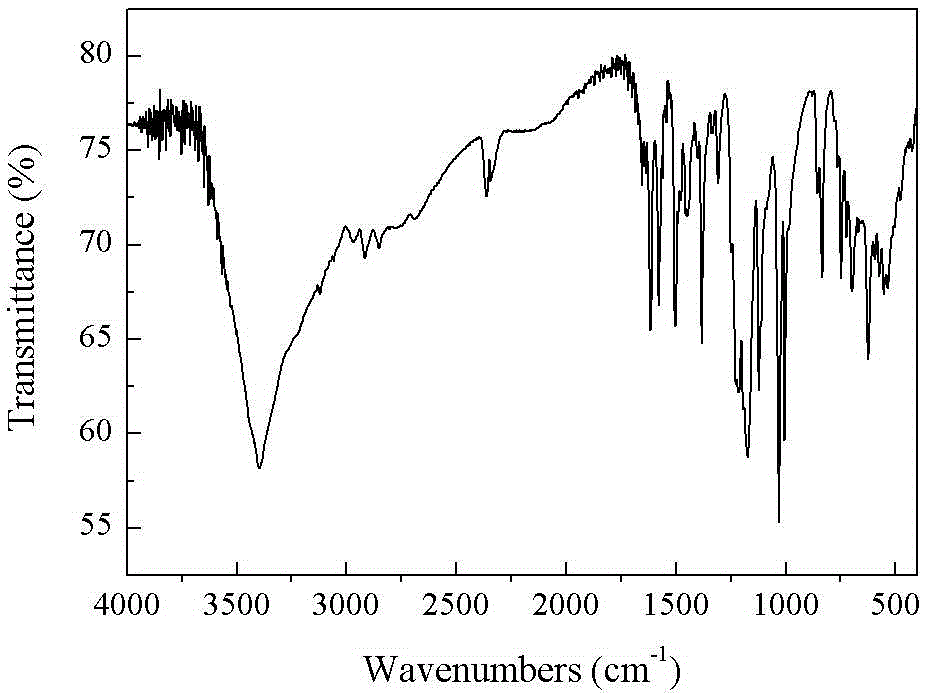

[0020] Stir and dissolve 0.1g of pyridoxal hydrochloride, 0.087g of anhydrous sulfanilic acid and 0.056g of potassium hydroxide in a mixed solvent of 10mL of methanol and 5mL of distilled water, then add 0.12g of nickel chloride hexahydrate and 5mL of distilled water at 50oC After condensing and reflux stirring for 2 hours, the reaction was stopped. After the reaction solution was cooled to room temperature, the liquid was filtered and allowed to stand for 2 days, and then crystals were precipitated. After filtration, the crystals were washed with methanol and dried to obtain a brownish-black crystal, which was the product. The product was characterized by infrared spectroscopy and single crystal X-ray diffraction to determine its crystal structure.

Embodiment 2

[0022] 0.1g of pyridoxal hydrochloride, 0.078g of anhydrous sulfanilic acid and 0.05g of potassium hydroxide were stirred and dissolved in a mixed solvent of 10mL of methanol and 5mL of distilled water, and then 0.058g of nickel nitrate hexahydrate and 5mL of distilled water were added. After stirring for 6 hours, the stirring was stopped, and the liquid was filtered and allowed to stand for three days before crystallization occurred. After filtration, the crystals were washed with methanol and dried to obtain a brownish-black crystal, which was the product. Product proves that it is the same product as Example 1 through infrared spectrum characterization.

Embodiment 3

[0024] 1.02g of pyridoxal hydrochloride, 0.95g of anhydrous sulfanilic acid and 0.63g of potassium hydroxide were stirred and dissolved in a mixed solvent of 50mL of methanol and 25mL of distilled water, then 1.57g of nickel sulfate hexahydrate and 25mL of distilled water were added, and the After stirring for 10 h, the stirring was stopped, and the liquid was filtered and allowed to stand for three days before crystallization occurred. After filtration, the crystals were washed with methanol and dried to obtain a brownish-black crystal, which was the product. Product proves that it is the same product as Example 1 through infrared spectrum characterization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com