Semi-aromatic sulfonated polyether ketone and preparation method thereof

A sulfonated polyetherketone, semi-aromatic technology, applied in electrical components, collectors/separators, circuits, etc., can solve the problems of high melting temperature, which is not conducive to the preparation of large-area membrane materials with uniform structure, and achieves reproducibility. Good performance, improved proton conductivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

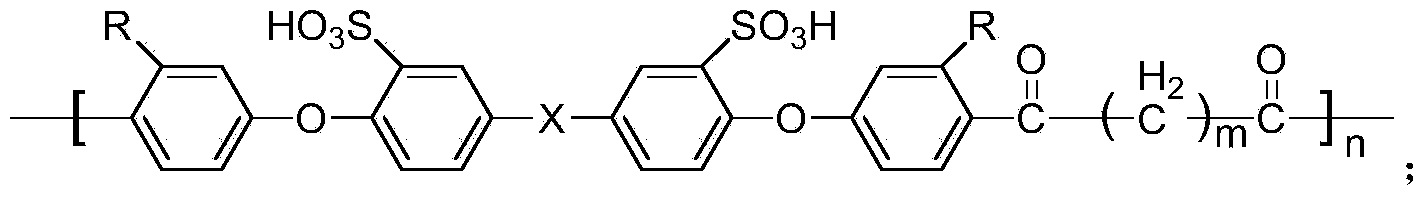

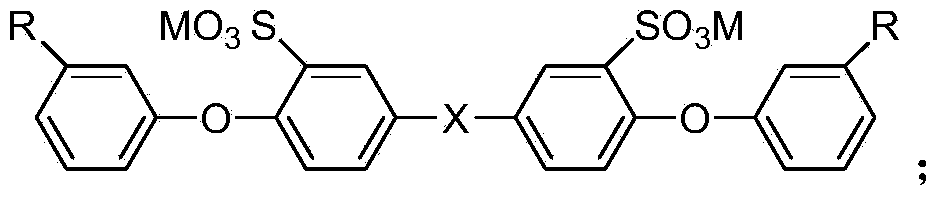

[0027] 0.01mol 1,4-bis(3-sodium sulfonate-4-phenoxy-benzoyl)benzene, 0.01mol sebacic acid and 30.3g Eaton's reagent, the mass ratio of sebacic acid and Eaton's reagent is 15: 1. Add it to the reaction flask of the spherical condenser connected to the calcium chloride drying tube at the top; the Eaton reagent is prepared by dissolving phosphorus pentoxide in methanesulfonic acid, with a mass percentage of 10%; stir at room temperature to dissolve the monomer, and heat up , reacted at 50°C for 10 hours. After the reaction is completed, the obtained solution is poured into distilled water, and the light yellow flocculent solid precipitates is octamethylene sulfonated polyether ketone, which is boiled and washed 5 times with distilled water to remove inorganic compounds. After drying, the yield was 97%.

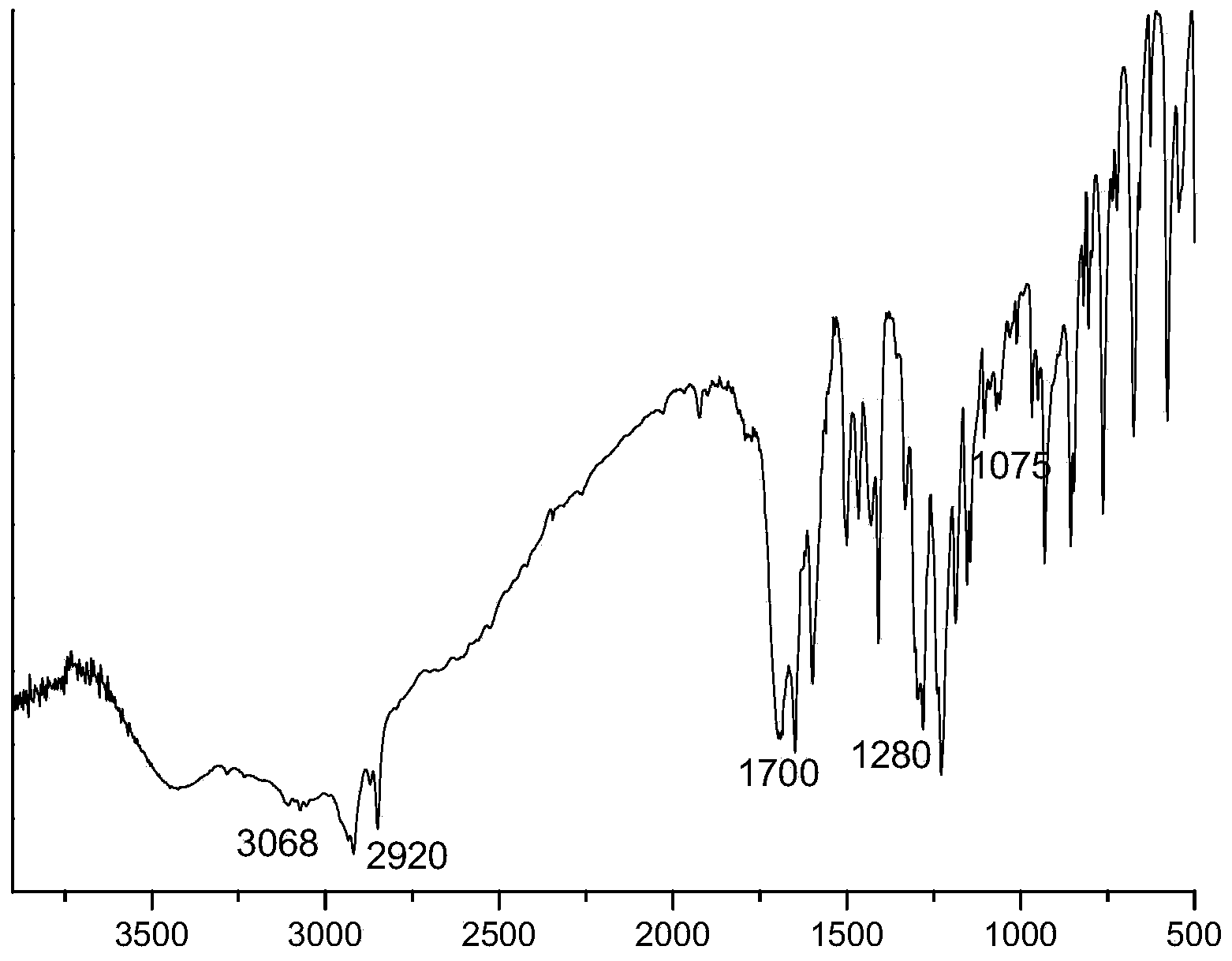

[0028] After testing: the infrared spectrogram of the semi-aromatic sulfonated polyetherketone prepared in this embodiment, refer to the attached figure 1 As shown, 1700cm -1 ...

Embodiment 2

[0030] In Example 1, the reaction at 50° C. for 10 hours was replaced by the reaction at 80° C. for 3 hours. Other monomer feed ratios, reaction conditions and processing steps were the same as in Example 1. The product is a pale yellow solid with a yield of 95%.

Embodiment 3

[0032] In Example 1, the fixed reaction temperature was set as a temperature program, that is, the reaction at 50°C for 10 hours was replaced by the reaction at 20°C for 2 hours, then the temperature was raised to 60°C for 2 hours, and then the reaction was performed at 80°C for 2 hours. Other monomer feed ratios and reaction conditions and processing steps are the same as in Example 1. The product is a pale yellow solid with a yield of 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com