Biosynthesis method for obtaining high-purity and high-efficiency microcystins (MCs) degrading enzyme (MlrA)

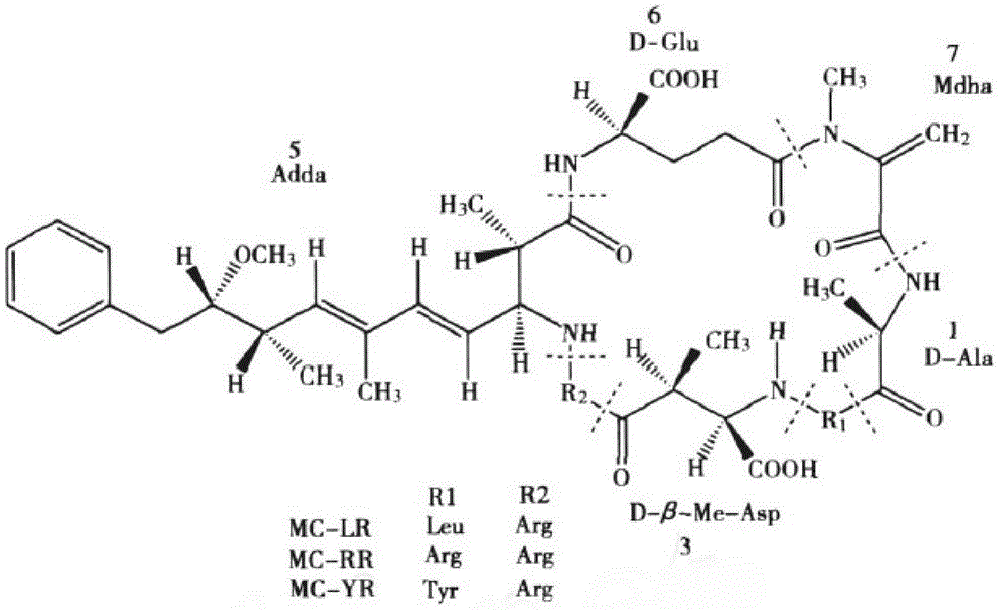

A algae toxin-degrading enzyme and biosynthetic technology, applied in the field of biotechnology applications or environmental protection, can solve problems such as time-consuming and material-consuming, affecting the application of algae-toxin-degrading enzymes, and harmful to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Construction of algal toxin degrading enzyme expression vector pMAL-C2X-MlrA

[0034] MlrA (nucleotide sequence shown in SEQ ID NO.1) was synthetically loaded into the cloning vector pUC19 to obtain pUC19-MlrA.

[0035] (1) Extraction of plasmid

[0036] Take 2 Erlenmeyer flasks containing 20mL LB (tryptone 10g / L, yeast extract 5g / L, NaCl 10g / L, ampicillin 30mg / L) medium, and put the plasmids containing pUC19-MlrA and pMAL-C2X Single colonies were added to the culture medium, cultivated overnight at 37°C and 220rpm, and the plasmid was extracted according to the SDS lysis method. After the plasmid extraction is completed, mark it and put it in a 4°C refrigerator for use in the next step.

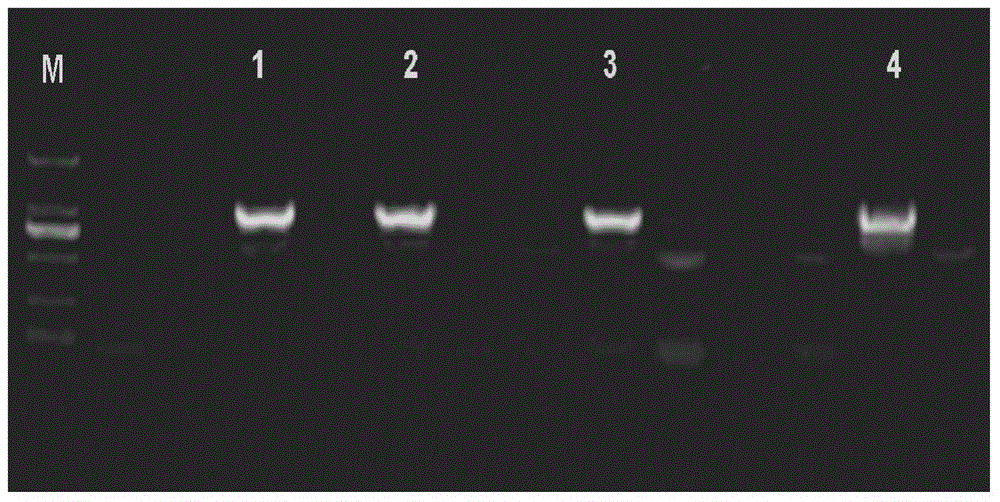

[0037] (2) PCR amplification of MlrA, MlrA and pMAL-C2X double enzyme digestion

[0038] PCR amplification reaction system: plasmid (pUC19-MlrA) 1 μL, 10×buffer 5 μL, dNTPs 4 μL, MlrA upstream primer 1 μL, MlrA downstream primer 1 μL, Taq DNA polymerase 1 μL, add ddH 2...

Embodiment 2

[0048] Example 2 Expression and Purification of Algae Toxin Degrading Enzymes

[0049] (1) Optimization of induction conditions

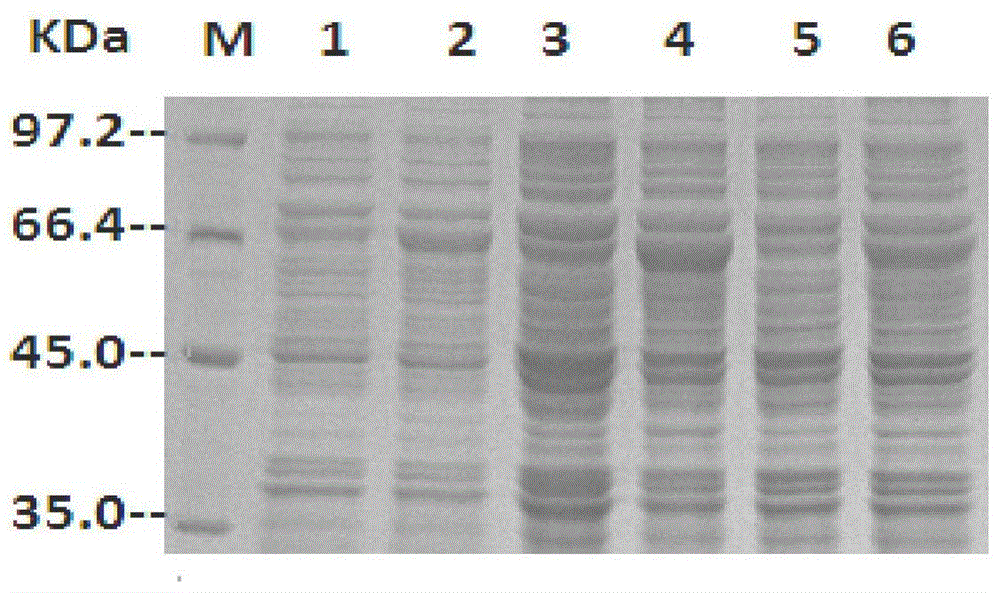

[0050] The concentration of the bacterial solution before induction, the concentration of the inducer IPTG, the induction expression temperature, and the induction time were optimized

[0051] The pMAL-C2X-MlrA plasmid in Escherichia coli DH5α was extracted, and the extracted plasmid was transformed into TB1 competent cells. Activate the expressing bacteria containing the target gene in a 20 mL LB medium flask containing 30 mg / L ampicillin at 37 °C and 220 rpm for 16 hours, take the activated bacterial liquid and inoculate it in 500 mL LB medium at an inoculation amount of 2.5%. Choose different induction conditions to induce expression. After induction of expression, the bacteria were collected, and the expression of the target protein was detected by SDS-PAGE to determine the optimal induction conditions. The result is as Figure 3-6 As show...

Embodiment 3

[0062] Example 3 Activity Detection of Algae Toxin Degrading Enzyme

[0063] (1) Cleaning balance of the chromatographic column

[0064] First turn on the high performance liquid chromatograph (Agilent 1200 LC) and elute the chromatographic column twice with methanol-containing aqueous solution from 100% to 2% gradient, and finally wash with 60% methanol to the baseline, and prepare the sample after the baseline leveled off for 20 minutes.

[0065] (2) Detection of samples

[0066] Sample information

[0067] The sample loading buffer is 0.05mol / L phosphate buffer, adjusted to pH=7.0; algae toxin MC-LR, MC-RR standard concentration is 10μg / mL, diluted with methanol to 5.0μg / mL, 1.0μg / mL , 0.5μg / mL, 0.25μg / mL; Methanol is HPLC chromatographically pure Fisher laboratory analytical reagent 4L; water is double distilled water, all samples need to be filtered with a 0.22μm filter membrane, and the bubbles dissolved in it are removed by ultrasonic waves.

[0068] Detection cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com