Extracting composition of camellia and preparation method of extracting composition

A technology of composition and extract, which is applied in the field of camellia extract composition and its preparation, can solve the problems of low efficiency of solvent method, complicated post-processing procedures, and large loss of nutrients, so as to avoid the introduction of harmful ingredients and be suitable for The effect of large-scale production and high content of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

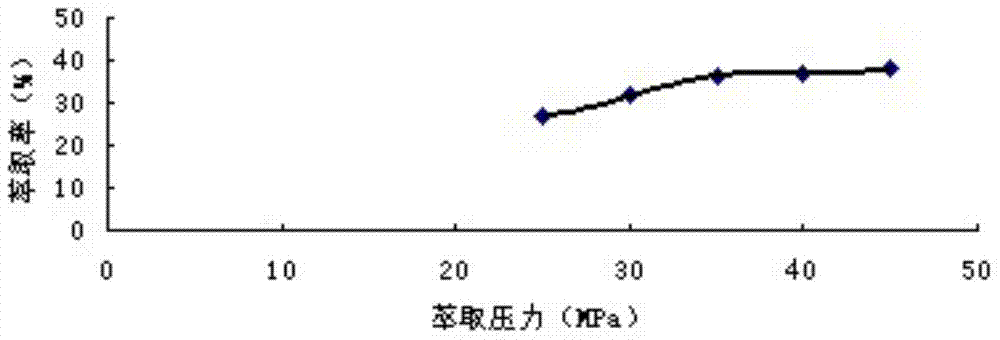

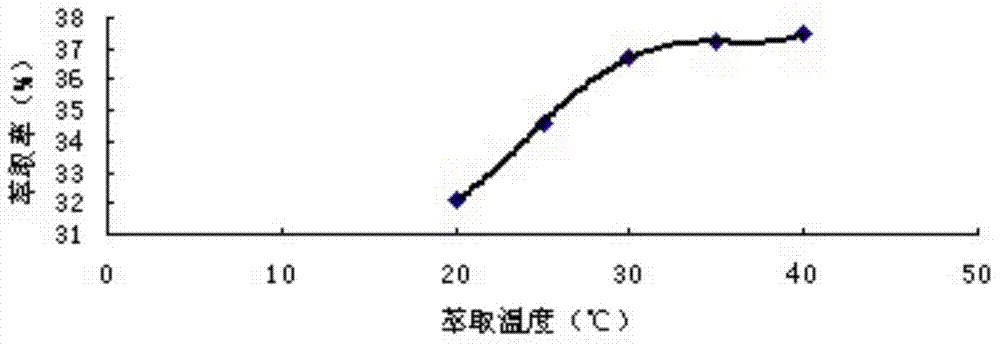

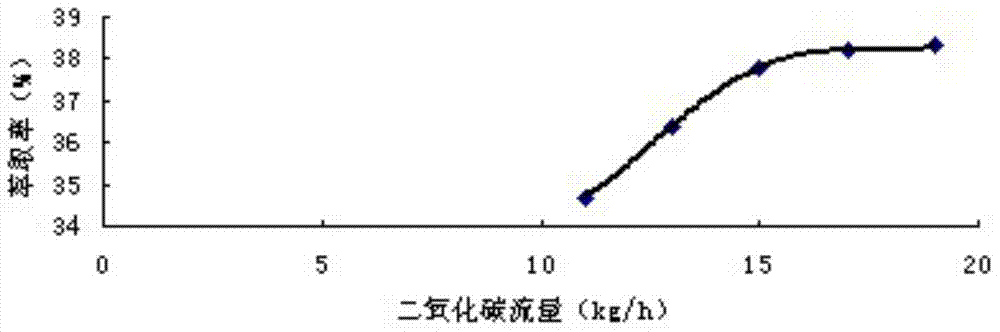

[0177] Get 400g of camellia seeds separated from the husk, pulverize, and cross a 24-mesh sieve to obtain 386g of camellia seed pulverization. Put the crushed camellia seeds into a 1L extraction kettle, set the extraction pressure to 25MPa, the extraction temperature to 20°C, the pressure of the separation kettle I to 11MPa, and the temperature to 45°C; the pressure of the separation kettle II to 7MPa, and the temperature to 38°C; the flow rate of carbon dioxide 11kg / h, the separated carbon dioxide is recycled, the equipment is stabilized and extracted for 90 minutes, the extracts in the separation kettle I and the separation kettle II are collected and combined, and then further separated to obtain 133g of light yellow transparent oily camellia extract, with a yield of 34.46% . Analyzing the extract composition of the camellia, its components are: 15% palmitic acid, 70% oleic acid, 8.5% mixture of linoleic acid and linolenic acid, 2.5% squalene, 2.5% β-carotene, 1.5% Vitamin...

Embodiment 2

[0179] Get 500g of camellia seeds separated from the husk, pulverize, and cross a 24-mesh sieve to obtain 453g of camellia seed pulverization. Put the crushed camellia seeds into a 1L extraction kettle, set the extraction pressure to 35MPa, the extraction temperature to 30°C, the pressure of the separation kettle I to 10MPa, and the temperature to 48°C; the pressure of the separation kettle II to 8MPa, and the temperature to 36°C; the flow rate of carbon dioxide 15kg / h, the separated carbon dioxide is recycled, the equipment is stabilized and extracted for 120min, the extracts in the separation kettle Ⅰ and the separation kettle Ⅱ are collected and combined, and then further separated to obtain 140.4g of light yellow transparent oily camellia extract, with a yield of 30.99 %. Analyzing the extract composition of the camellia, its components are: 25% palmitic acid, 55% oleic acid, 14.5% mixture of linoleic acid and linolenic acid, 1.5% squalene, 2.5% β-carotene, 1.5% Vitamin E...

Embodiment 3

[0181] Get 600g of camellia seeds separated from the husk, pulverize, and cross a 24-mesh sieve to obtain 568g of camellia seed pulverization. Put 450g of crushed camellia seeds into a 1L extraction kettle, set the extraction pressure to 45MPa, the extraction temperature to 40°C, the pressure of the separation kettle I to 10MPa, and the temperature to 50°C; the pressure of the separation kettle II to 8MPa, and the temperature to 35°C; carbon dioxide The flow rate is 19kg / h, and the separated carbon dioxide is recycled. After the equipment is stable, it is extracted for 120 minutes, and the extracts in the separation kettle I and the separation kettle II are collected and combined, and then further separated to obtain 149.3g of light yellow transparent oily camellia extract. The yield is 33.18%. The extract composition of the camellia was analyzed, and its components were: 25% palmitic acid, 67.3% oleic acid, 5% mixture of linoleic acid and linolenic acid, 2% squalene, 0.2% β-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com