Novel strain for producing butanol and method for producing butanol

A technology of butanol and strains, applied in the field of butanol-producing strains, can solve problems such as inability to use fermentation to produce butanol, and achieve the effects of great social significance and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

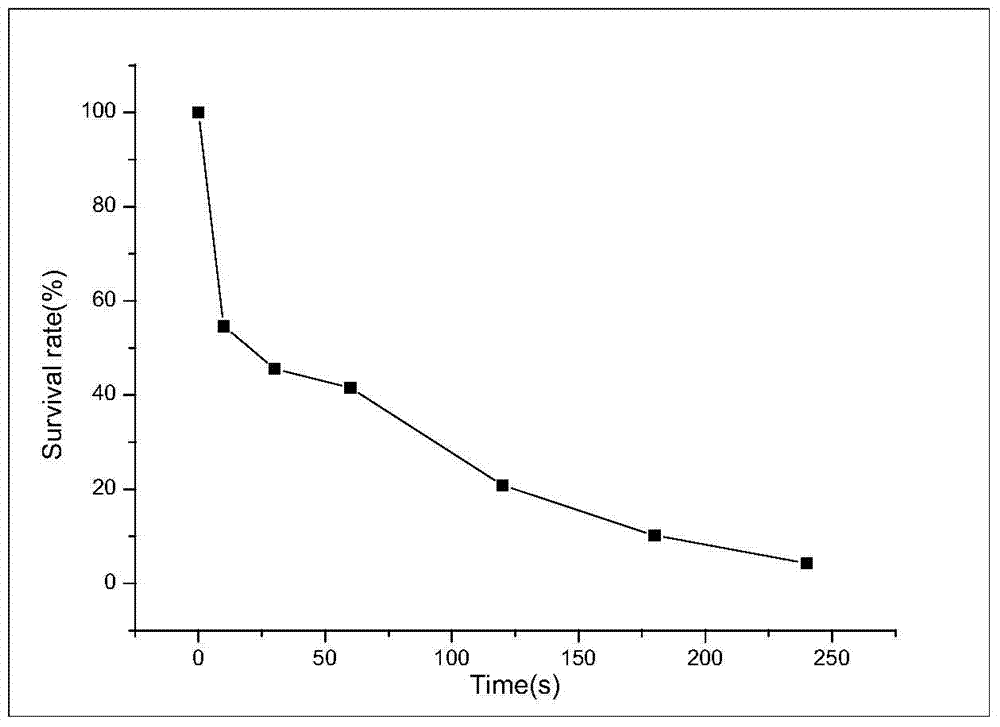

[0040] Example 1: This example illustrates the method for screening Clostridium beinii IT66 by mutagenesis using the original strain IB4 of Clostridium beinii as the starting strain.

[0041] The source of the starting strain: the strain disclosed in the previous literature of the applicant's inventor team, Guo et al. (J Ind Microbiol Biotechnol, 2011, 99 (3), 401-407.). The applicant hereby declares that it guarantees to distribute the biological materials of this starting strain to the public free of charge within 20 years from the date of application.

[0042] The medium formula used in this embodiment (% is mass percentage):

[0043] (1) Solid plate medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dihydrogen phosphate Potassium 0.1%, ferrous sulfate heptahydrate 0.01%, agar 1.5%, the rest is water, pH 6.

[0044] (2) Resazurin plate medium: ...

Embodiment 2

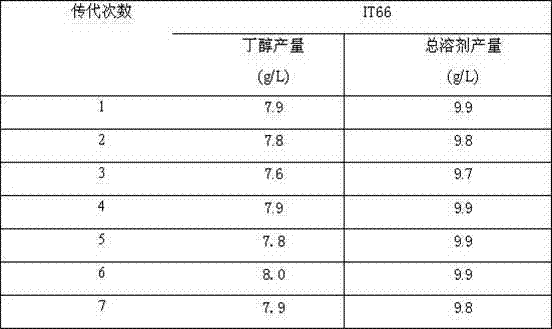

[0065] Embodiment 2: This embodiment illustrates the method that Clostridium beinii IT66 produces butanol

[0066] The medium formula used in this embodiment:

[0067] Plate medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dipotassium hydrogen phosphate 0.1%, Ferrous sulfate heptahydrate 0.01%, agar powder 1.5%, the rest is water, pH 6.

[0068] Seed medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dipotassium hydrogen phosphate 0.1%, Ferrous sulfate heptahydrate 0.01%, the rest is water, pH 6.

[0069] Fermentation medium: non-detoxified corncob acid hydrolysis sugar solution 3%; ammonium acetate 0.22%, potassium dihydrogen phosphate 0.05%, dipotassium hydrogen phosphate 0.05%, magnesium sulfate heptahydrate 0.02%, m...

Embodiment 3

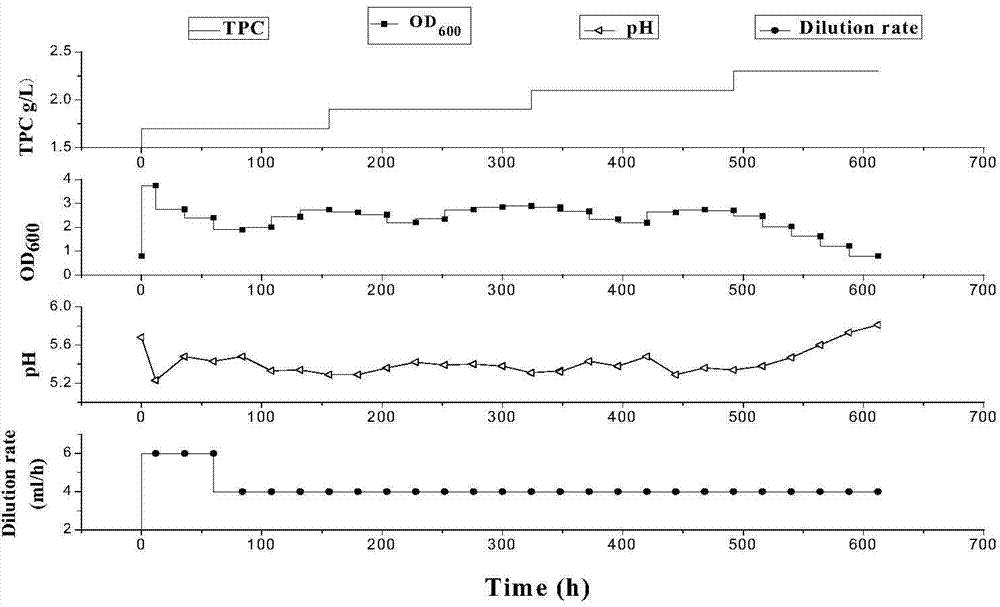

[0076] Embodiment 3: This embodiment illustrates the method that Clostridium beinii IT66 produces butanol

[0077] The medium formula used in this embodiment:

[0078] Plate medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dipotassium hydrogen phosphate 0.1%, Ferrous sulfate heptahydrate 0.01%, agar powder 1.5%, the rest is water, pH 6.

[0079] Seed medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dipotassium hydrogen phosphate 0.1%, Ferrous sulfate heptahydrate 0.01%, the rest is water, pH 6.

[0080] Fermentation medium: non-detoxified corncob acid hydrolyzed sugar solution 3.5%; ammonium acetate 0.22%, potassium dihydrogen phosphate 0.05%, dipotassium hydrogen phosphate 0.05%, magnesium sulfate heptahydrate 0.02%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com