A method for the production of bio-based chemicals using highly cellulose hydrolyzate tolerant Escherichia coli

A technology of cellulose hydrolyzate and Escherichia coli, applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve the problems of difficult operation of foreign plasmids, unstable and easy degradation of host strains, and achieve Mild conditions, easy genetic engineering, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: strain mutagenesis and screening

[0026] Measure the number of cells in the suspension by hemocytometer, and dilute to 105-106 cells / mL with sterile water. Take 5mL of bacterial suspension in a 9cm-diameter plate, put it into a rotor sterilized by 70% ethanol, and stir it magnetically. Put it under a 30w ultraviolet lamp at a distance of about 25cm. After a certain period of irradiation (1s, 2s, 5s, 15s, 30s, 60s), take 0.1mL and spread it on a lignocellulose hydrolyzate selective medium plate and culture it in the dark at 37°C After 16-18 hours, count the number of colonies on the plate, calculate the lethal rate, and draw the lethal curve.

[0027] The lignocellulose hydrolyzate culture medium is obtained by the following method: add 450mL distilled water and the following components in a 1 L beaker to dissolve it in water: NH 4 Cl 0.3~0.5g, Na 2 HPO 4 2~3g, KH 2 PO 4 1 ~ 2g, adjust the pH to 7.4 with 1 M NaOH and adjust the total volume to 450 ~ 550...

Embodiment 2

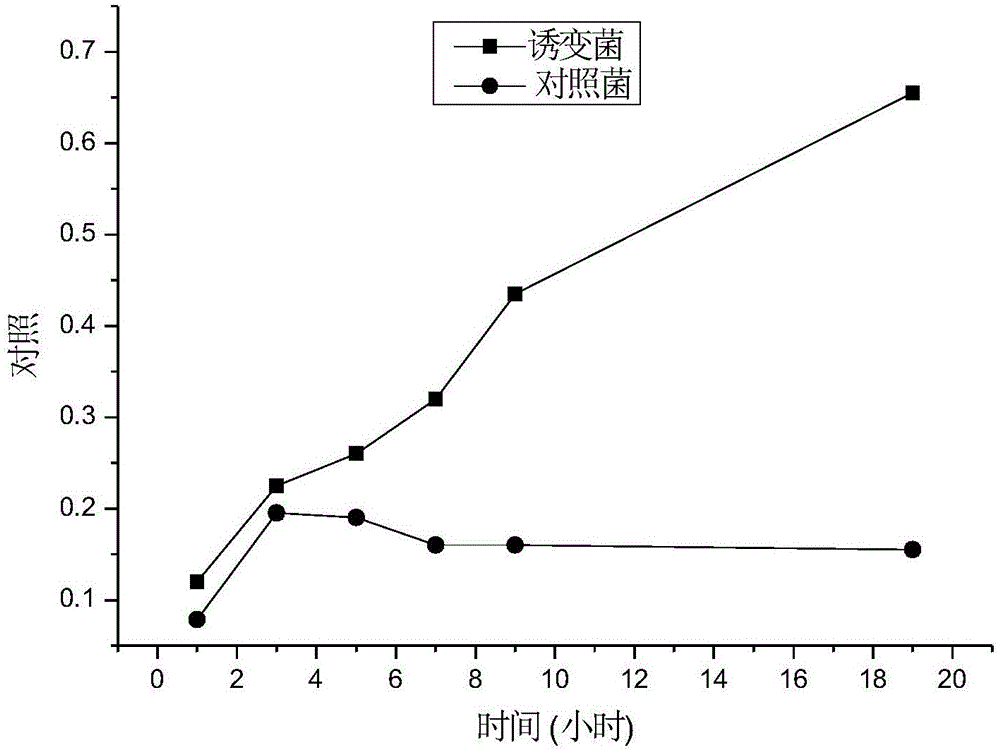

[0033] Example 2: Verification of strain tolerance to lignocellulose hydrolyzate

[0034] Preparation of lignocellulose alkenoic acid hydrolyzate: take the dried stalks, filter the crushed corn stalks with 40 mesh according to the solid-liquid ratio of 5%, hydrolyze them in 1% sulfuric acid at 100°C for 5 hours, filter and adjust the pH It is later used as a carbon source for cellulose hydrolysis, and its main components are glucose, xylose, and furfural, and also contains a small amount of hydroxymethylfurfural, acetic acid, phenolic compounds, and sodium sulfate produced by neutralization with sodium hydroxide.

[0035] Pick the strains resistant to lignocellulose hydrolyzate obtained by screening, use the strains that have not undergone mutagenesis, and inoculate them in a test tube containing 2 mL of LB medium, and inoculate when the cell density is about 1 In a 250mL shake flask equipped with 50mL of the above-mentioned lignocellulose hydrolyzate 3% as the sole carbon sou...

Embodiment 3

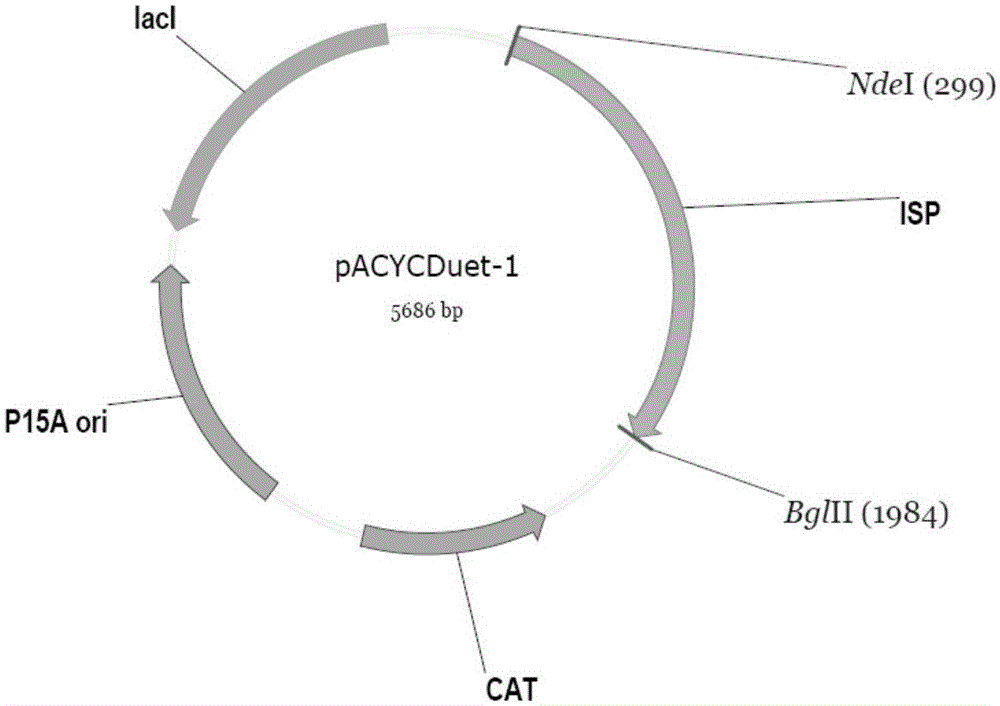

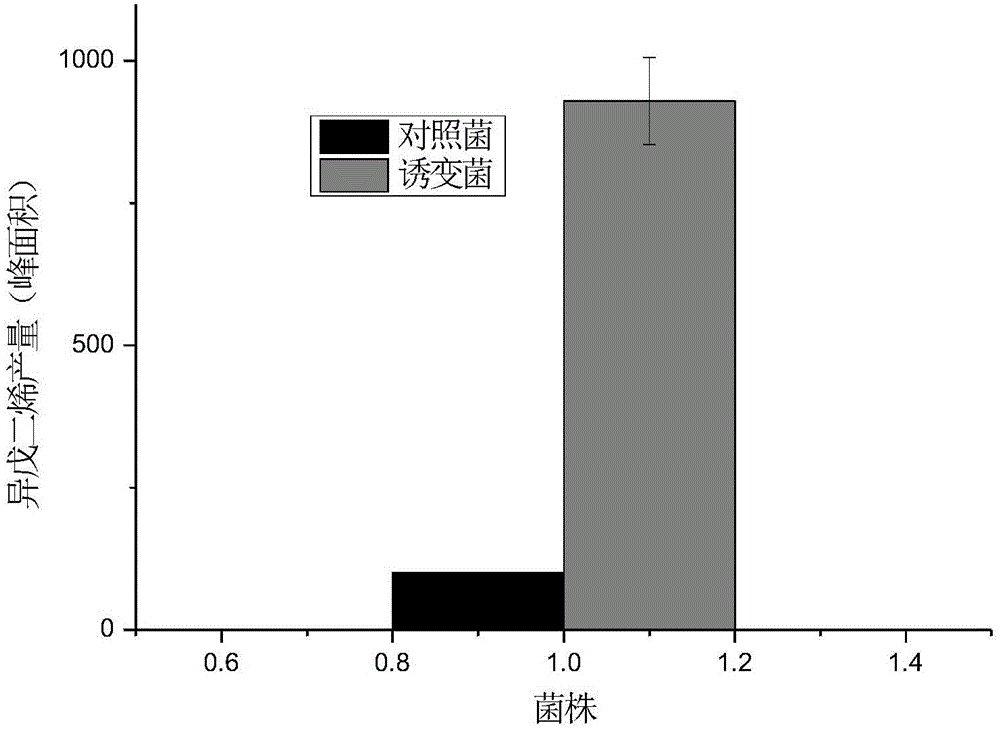

[0038] Example 3: Synthesis of bio-based chemicals using cellulose hydrolyzate tolerant host bacteria

[0039] Competent strain preparation:

[0040] 1. Pick a single colony with a diameter of about 2 to 3 mm from an overnight (16-20h) culture plate at 37°C. Such a single colony was inoculated into a sterilized 30 ml test tube containing 5 ml of LB broth, and cultured overnight at 37°C with shaking.

[0041] 2. Transfer 0.2 ml of overnight culture to a 50 ml sterilized Erlenmeyer flask containing 15 or 20 ml of LB. Shake culture at 37°C for 2 to 2.5 hours (the bacteria are in the logarithmic growth phase at this time).

[0042] 3. Centrifuge at 4000rpm for 5 minutes at room temperature to collect the logarithmic phase cells. Discard the medium and keep the cell pellet.

[0043] 4. Add 10 mL of ice-cold MgCl 2 -CaCl 2 solution, and beat lightly.

[0044] Cells were collected by centrifugation at 4000 rpm for 10 minutes at 5.4°C.

[0045] 6. Discard MgCl 2 -CaCl 2 solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com