Lithium-sulfur cell anode composite material and its preparation method and use

A technology for composite materials and lithium-sulfur batteries, applied in battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems that materials containing silicon-oxygen groups cannot uniformly disperse carbon-sulfur compounds and limit development, etc. Achieve the effect of suppressing the shuttle effect, low product cost, and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

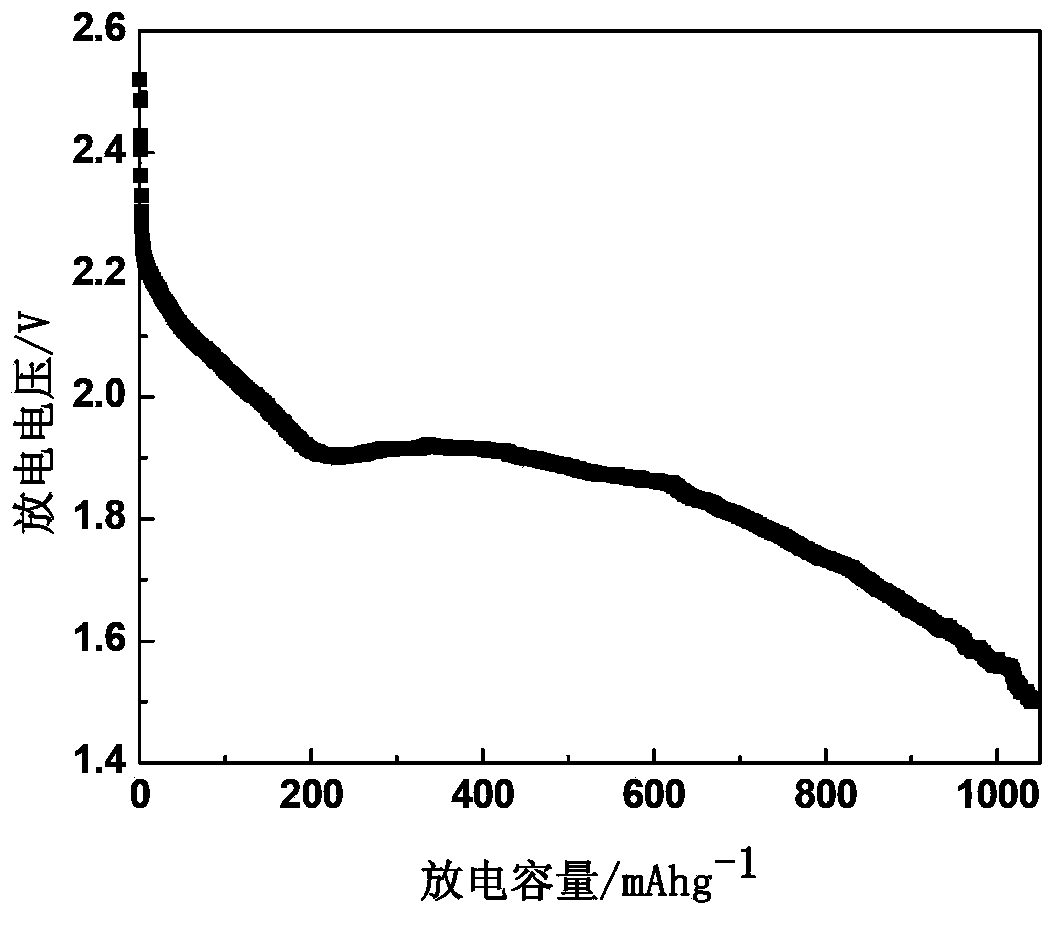

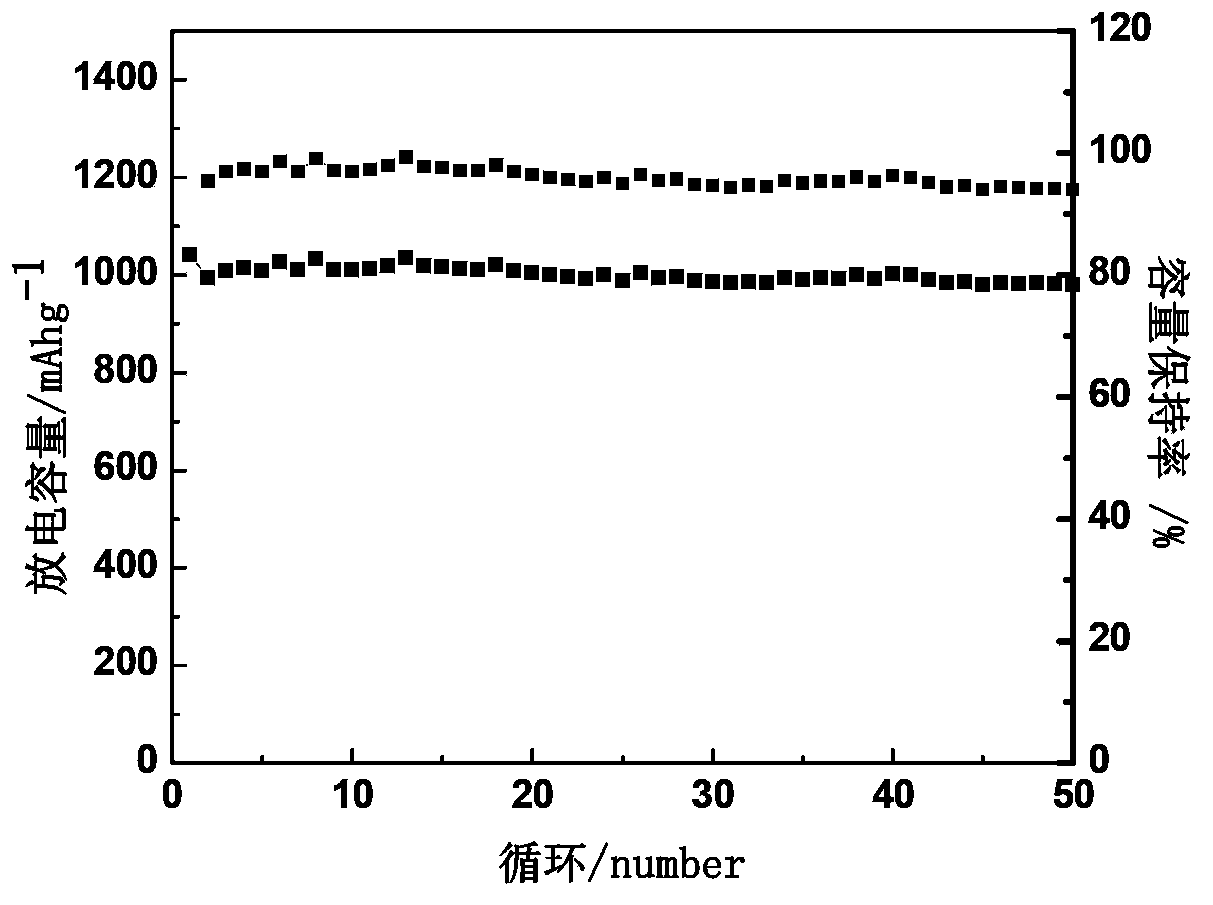

Embodiment 1

[0035] Mix thiophenemethanol and tetraethyl orthosilicate at a molar ratio of 10:1, stir at room temperature to fully dissolve to form a transparent solution A; add 2M sodium hydroxide solution to solution A, continue stirring, and adjust the pH The value is 7, so that it generates a yellow-orange liquid-solid product B; the product B is distilled under reduced pressure at -0.1MPa for 5h at 100°C to obtain the product C; the product C is added to the mixed solution of toluene and n-hexane (V: V =10:1), recrystallized at -10°C to obtain product D; washed product D with n-hexane for 3 times, and vacuum dried to obtain product E; dissolved solid powder E in ethanol (solution concentration: 1%) , mixed uniformly at 0°C to form solution F; take elemental sulfur, cetyl ammonium bromide (CTAB), and ferric chloride and dissolve them in ethanol (solution F) at a mass ratio of 1:1:0.1:1 concentration is 0.1%), and stirred for 10 minutes to form solution G; slowly added solution F to sol...

Embodiment 2

[0037] Mix aniline alcohol and methyl orthosilicate in a molar ratio of 1:1, stir at room temperature to fully dissolve to form a transparent solution A; add 0.2M sodium hydroxide solution to solution A, continue stirring, and adjust the pH The value is 7, so that it generates a yellow-orange liquid-solid product B; the product B is distilled under reduced pressure at -0.1MPa for 5h at 150°C to obtain the product C; the product C is added to the mixed solution of toluene and n-hexane (V: V =1:1), recrystallized at -10°C to obtain product D; washed product D with n-hexane for 5 times, and vacuum dried to obtain product E; dissolved solid powder E in water and mixed evenly at 0°C to form solution F (solution concentration is 80%); take elemental sulfur, polyethylene oxide-polypropylene oxide-polyethylene oxide, and ammonium persulfate in a mass ratio of 1:5:1:5. In the solvent in step (6), stir for 10 minutes to form solution G; slowly add solution F to solution G (solution concen...

Embodiment 3

[0039] Mix aniline alcohol and tetraethyl orthosilicate at a molar ratio of 10:1, stir at room temperature to fully dissolve to form a transparent solution A; add 0.1M sodium bicarbonate solution to solution A, continue stirring, and adjust the pH The value is 9, so that it generates a yellow-orange liquid-solid product B; the product B is distilled under reduced pressure at -0.1MPa for 5h at 150°C to obtain the product C; the product C is added to the mixed solution of toluene and n-hexane (V: V =1:1), recrystallized at -10°C to obtain product D; washed product D with n-hexane for 5 times, and vacuum dried to obtain product E; dissolved solid powder E in water and mixed evenly at 0°C , forming solution F (solution concentration is 10%); take elemental sulfur, polyethylene oxide-polypropylene oxide-polyethylene oxide, and hydrogen peroxide in a ratio of 1:5:1:8 by mass and dissolve in the step In the solvent in (6), stir for 30 minutes to form solution G; slowly add solution F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com