A flue gas desulfurization and denitrification method and device

A desulfurization, denitrification and flue gas technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of large equipment volume and low flue gas temperature, achieve small size, simplify equipment structure, and reduce electric heating. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

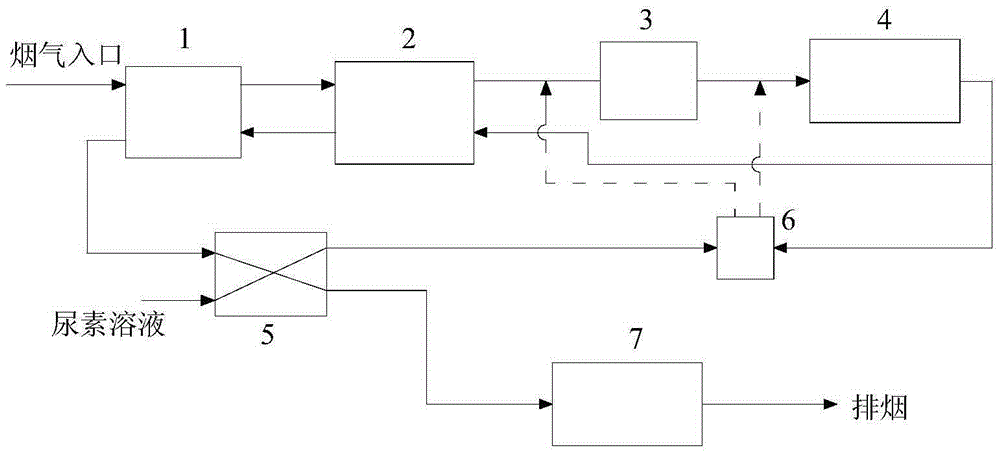

[0040] like figure 2 Shown is the flue gas desulfurization and denitrification method and device of the present invention, the method is used for desulfurization and denitrification of flue gas from a marine diesel engine with a power of 550kW and a rotation speed of 750rpm. The exhaust temperature of the diesel engine drops to about 250°C at low speed, the maximum flow of flue gas is 4.4t / h, NO x Weighted emissions are 9.6g / kWh. When the system starts and stops, the flue gas passes through passage 1 to react with the incoming solid particles and enters the flue gas heating process after passing through the dust collector. When the system is in normal operation, the flue gas directly enters the flue gas heating process through passage 2. The flue gas first enters the heat exchanger for heat exchange and temperature rise, so that the temperature of the flue gas rises to about 290°C. The heated smoke is raised to about 340°C by a heat pump, and then the flue gas is heated by a...

Embodiment 2

[0044] This embodiment is basically the same as the embodiment 1, the difference is that: both sides of the heat transfer surface of the flue gas partition wall of the heat exchanger are coated with a coating that enhances heat radiation, and the heat radiation absorption rate of the coated coating layer is 0.95. The product of urea hydrolysis and a part of the SCR reactor outlet flue gas enter the static mixer, and the NH in the mixed gas 3 The volume fraction reaches 8%, and it is sprayed into the pipeline between the electric heater and the SCR reactor through the ammonia injection grid.

Embodiment 3

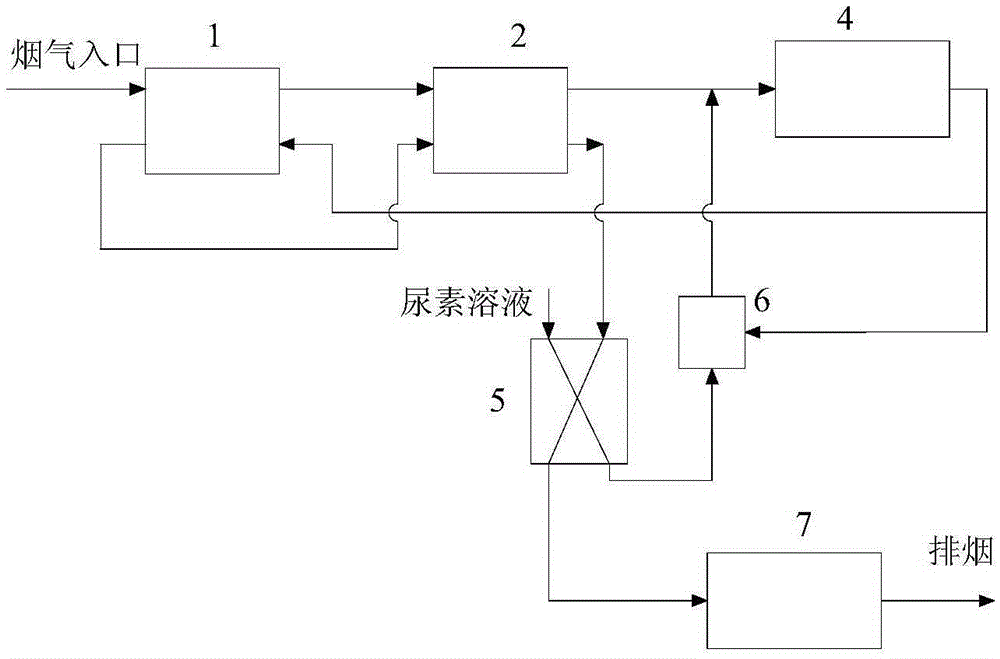

[0046] like image 3 Shown is the flue gas desulfurization and denitrification method and device of the present invention, the method is used for desulfurization and denitrification of flue gas from a marine diesel engine with a power of 1500kW and a rotational speed of 1760rpm. The exhaust temperature of the diesel engine drops to about 260°C at low speed, the maximum flow of flue gas is 13.6t / h, NO x Weighted emissions are 9.38g / kWh. When the system starts and stops, the flue gas reacts with the incoming solid particles through passage 1 and enters the flue gas heating process after passing through the dust collector. When the system is in normal operation, the flue gas directly enters the flue gas heating process through passage 2. The flue gas first enters the heat exchanger for heat exchange and temperature rise, so that the temperature of the flue gas rises to about 320°C, and the temperature of the heated smoke is raised to about 380°C through the heat pump.

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com