Method for synthesis of betamipron in continuous-flow microreactor

A technology of betamipron and microreactor, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as low purification yield and complicated operation, and achieve simplified purification operation and increased yield , the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

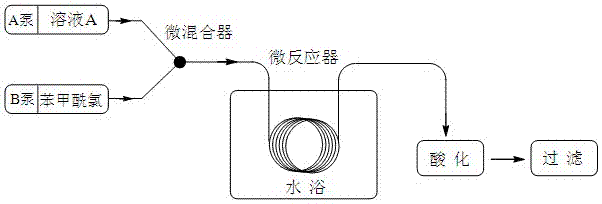

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Microfluidic Synthesis of Betamipron (I)

[0026] 0.01 mol alanine, 0.01 mol sodium hydroxide and 0.022 mol sodium bicarbonate were dissolved in 13.5 ml water to obtain solution A and 1.16 ml benzoyl chloride, respectively at a flow rate of V A = 24 ul / min and V B = 2.06 ul / min is simultaneously propelled by pump A and pump B to inject into the mixer and then enter the reactor for reaction. The diameter of the reactor microtube is 0.7 mm, the length of the tube is 1 m, and the temperature of the water bath is 0 o C, the solution of the collected betamipron sodium salt was acidified to pH=2 with concentrated hydrochloric acid, the betamipron solid was collected by filtration, washed with water and dried, and vacuum-dried to constant weight to obtain 1.82 g, with an HPLC purity of 95%. The rate is 90% (according to alanine).

[0027] 1 H NMR (CD 3 OD, ppm): δ 2.65 (t, J = 6.9 Hz, 2H), 3.62 (t, J = 6.9 Hz, 2H), 7.40-7.50 (3H), 7.79 (m, 2H). 13 C NMR (...

Embodiment 2

[0029] 0.01 mol alanine, 0.01 mol sodium hydroxide and 0.022 mol sodium bicarbonate were dissolved in 13.5 ml water to obtain solution A and 1.16 ml benzoyl chloride, respectively at a flow rate of V A = 4 ul / min and V B = 0.35 ul / min is simultaneously propelled by pump A and pump B to inject into the mixer and enter the reactor for reaction. The diameter of the microtube of the reactor is 0.7 mm, the length of the tube is 1 m, and the temperature of the water bath is -5 o C, the solution of the collected betamipron sodium salt was acidified to pH=2 with concentrated hydrochloric acid, the betamipron solid was collected by filtration, washed with water and dried, and vacuum-dried to constant weight to obtain 1.66 g, with an HPLC purity of 86%. The rate is 74% (according to alanine).

Embodiment 3

[0031] 0.01 mol alanine, 0.01 mol sodium hydroxide and 0.022 mol sodium bicarbonate were dissolved in 13.5 ml water to obtain solution A and 1.16 ml benzoyl chloride, respectively at a flow rate of V A = 28ul / min and V B = 2.41ul / min is simultaneously propelled by pump A and pump B to inject into the mixer and enter the reactor for reaction. The diameter of the microtube of the reactor is 0.7 mm, the length of the tube is 1 m, and the temperature of the water bath is 0 o C, the solution of the collected betamipron sodium salt was acidified to pH=2 with concentrated hydrochloric acid, the betamipron solid was collected by filtration, washed with water and dried, and vacuum-dried to constant weight to obtain 1.78 g, with an HPLC purity of 92%. The rate is 85% (according to alanine).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com