Preparation method of fluticasone propionate particles and applications of the particle

A technology of fluticasone propionate and microparticles, which is applied to inhalation aerosols and inhalation powder aerosols, to prepare fluticasone propionate microparticles with a particle size D98 below 5 μm, and to prepare nasal sprays, which can solve the problem of small batches of raw materials and environmental pollution High roundness, low energy consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 preparation of fluticasone propionate microparticles

[0042] method:

[0043] 1) Preparation of fluticasone propionate solution A: add 10 g of fluticasone propionate to 550 g of polyethylene glycol 400, heat and stir to dissolve completely, and obtain solution A;

[0044] 2) Preparation of anti-solvent B: Take 2.05g of Tween 80 and 1.91g of benzalkonium chloride, dissolve them in water, add water to 17050g, and obtain anti-solvent B;

[0045] 3) Mixing method of solution A and anti-solvent B: under stirring, add solution A into anti-solvent B, and keep stirring for 10 minutes to obtain a suspension.

[0046] result:

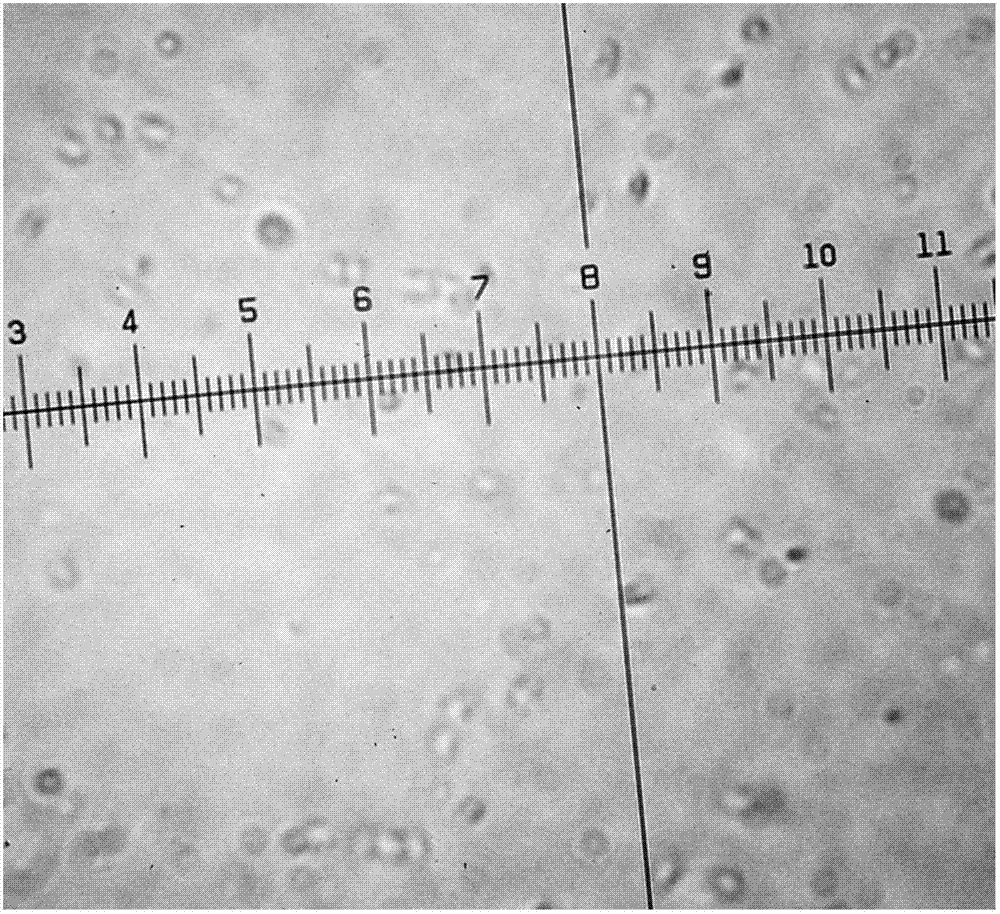

[0047] Detected with a laser particle size analyzer, the D98 of the fluticasone propionate particles in the suspension is 3.47 μm, see figure 1 .

Embodiment 2~6

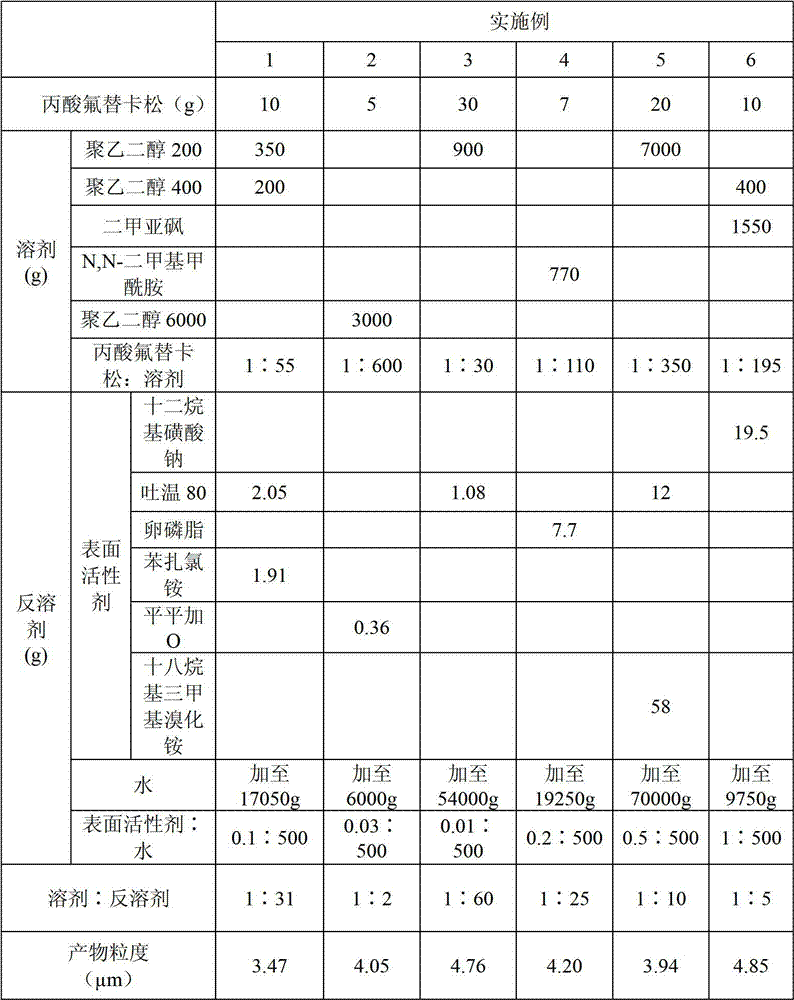

[0049] According to the operation method of Example 1 and the types and amounts of each material in Table 1, fluticasone propionate microparticles were prepared.

[0050] The particle size of the obtained product fluticasone propionate microparticles is shown in Table 1.

[0051] Table 1 The types, dosage and particle size of each material used in the preparation of fluticasone propionate microparticles

[0052]

Embodiment 7

[0067] Get the suspension containing fluticasone propionate microparticles obtained in 880g embodiment 1, 0.5g Tween 80, 2.5g phenethyl alcohol, 5g glucose, 1.2g microcrystalline cellulose, 2.5g sodium carboxymethylcellulose, 0.2g BHT, add water to 1000g, stir, mix evenly, the liquid medicine that mixes is filled with brown glass bottle, and every bottle filling capacity is 16g, and spray pump head is installed, gets fluticasone propionate nasal spray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com