Method for preparing antioxidant for oil and fat

An antioxidant and oil technology, which is applied in the field of preparation of oil antioxidants, can solve problems such as unresearched, and achieve good antioxidant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

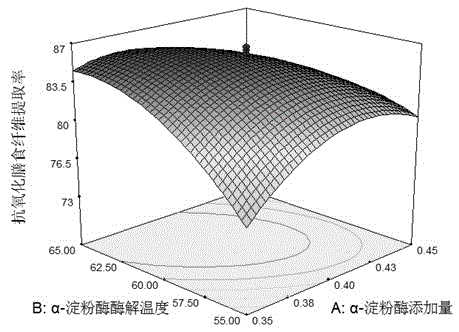

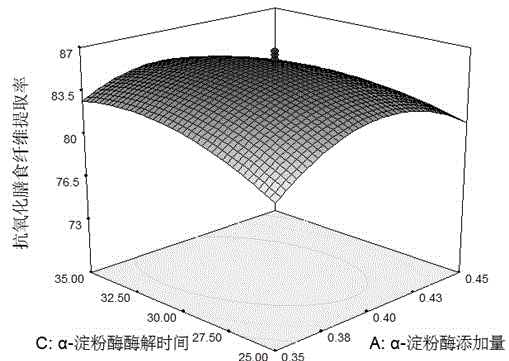

[0027] A method for preparing an oil antioxidant, the method comprising the following steps: (1) washing grape pomace with water to remove impurities, and then performing freeze-drying treatment at a temperature of -55°C and a vacuum degree of 17.33Pa, and drying the freeze-dried grape skin The slag was ground until the particle size was less than 0.5mm, and then ultrafinely pulverized at -10°C for 15 minutes for modification to obtain grape skin pomace powder; Enzymolysis, the enzymolysis temperature is 50-70°C, the enzymolysis time is 20-40min, the amount of α-amylase added is 0.3-0.5% of the mass of grape pomace powder, the pH of the enzymolysis is 4.3, and then use Protease P-3910 is used for enzymolysis, the enzymolysis temperature is 70°C, the enzymolysis time is 40min, the amount of protease added is 0.3-0.5% of the mass of grape pomace powder, the pH of the enzymolysis is 4.3, after the enzymolysis, the centrifugal force Centrifuge at 3000g for 15min to obtain the supe...

Embodiment 1

[0030] The research of embodiment 1 natural antioxidant extraction

[0031] 1 Materials and methods

[0032] 1.1 Materials and reagents

[0033]

[0034] 1.2 Main instruments and equipment

[0035]

[0036] 1.3 Experimental method

[0037] 1.3.1 Determination of grape pomace components

[0038] Determination of moisture: GB304-87; Determination of crude fat: Soxhlet extraction method in GB5512-85; Determination of crude protein: GB6432-94 standard method; Determination of ash: GB5009.4-85; Starch content Determination of: GB5009.9-85; Determination of tannin content: Spectrophotometry NY / T1600-2008; Determination of total sugar content: GB / T15038-2006; Determination method of anthocyanidin: Spectrophotometry; Determination of total dietary fiber: AACC32-07.

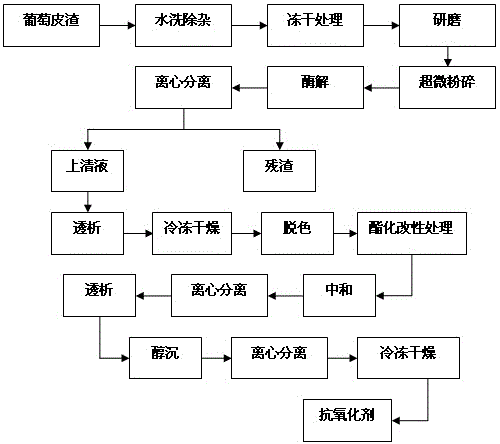

[0039] 1.3.2 Process flow (see figure 1 )

[0040] 1.3.3 Calculation formula

[0041]

[0042] 2 Results and Discussion

[0043] 2.1 Analysis of the basic components of grape pomace

[0044] Table 1-1 M...

Embodiment 2

[0068] Embodiment 2 Antioxidant research of antioxidant of the present invention

[0069] 1 Materials and methods

[0070] 1.1 Materials and reagents

[0071]

[0072] 1.2 Main instruments and equipment

[0073] equipment factory UV-2000 UV Spectrophotometer Shanghai Jinghua Technology Instrument Co., Ltd. electronic analytical balance Merlot-Toledo Instruments (Shanghai) Co., Ltd. Electric constant temperature oven East China Standard Oven Co., Ltd.

[0074] 1.3 Experimental method

[0075] 1.3.1 Determination of oil peroxide value: refer to GB5538-85.

[0076] 1.3.2 Determination of scavenging DPPH free radicals

[0077] Take 4 mL of the sample solution with a certain concentration, add 1 mL of DPPH solution prepared with methanol, and make the final concentration of DPPH 0.2 mmol / L, shake vigorously and mix well, then place it in a dark room for 30 min, and measure the absorbance at 517 nm . Calculate the DPPH clearance rate acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com