Preparation method for nanometer zinc stannate

A technology of nano-zinc stannate and zinc stannate, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high price, uneven particle size, lack of application examples of zinc stannate, etc., and achieve simple process , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Dissolve 1.0g of tin oxide and 0.6g of zinc chloride in 50mL of 0.5moL / L hydrochloric acid solution, add distilled water to dilute to 120mL, then add 20mL of 15% aqueous hydrogen peroxide solution, and stir 0.5moL / L ammonia solution was added dropwise to adjust the pH value to about 8. After the dropwise addition, the temperature was raised to 60°C and the temperature was controlled for 5 hours to react. The obtained white precipitate was filtered and washed, and the precipitate was dispersed in 40mL of ethanol And 0.1 g of sodium dodecylsulfonate was added. Finally, pour the above solution into a polytetrafluoroethylene high-pressure reaction kettle, carry out solvothermal reaction at a temperature of 200°C, wash the precipitate repeatedly with deionized water, filter it with suction, dry it at a temperature of 100°C, and then empty it at 600°C The zinc stannate with particle size of 25nm was obtained by calcining under atmosphere.

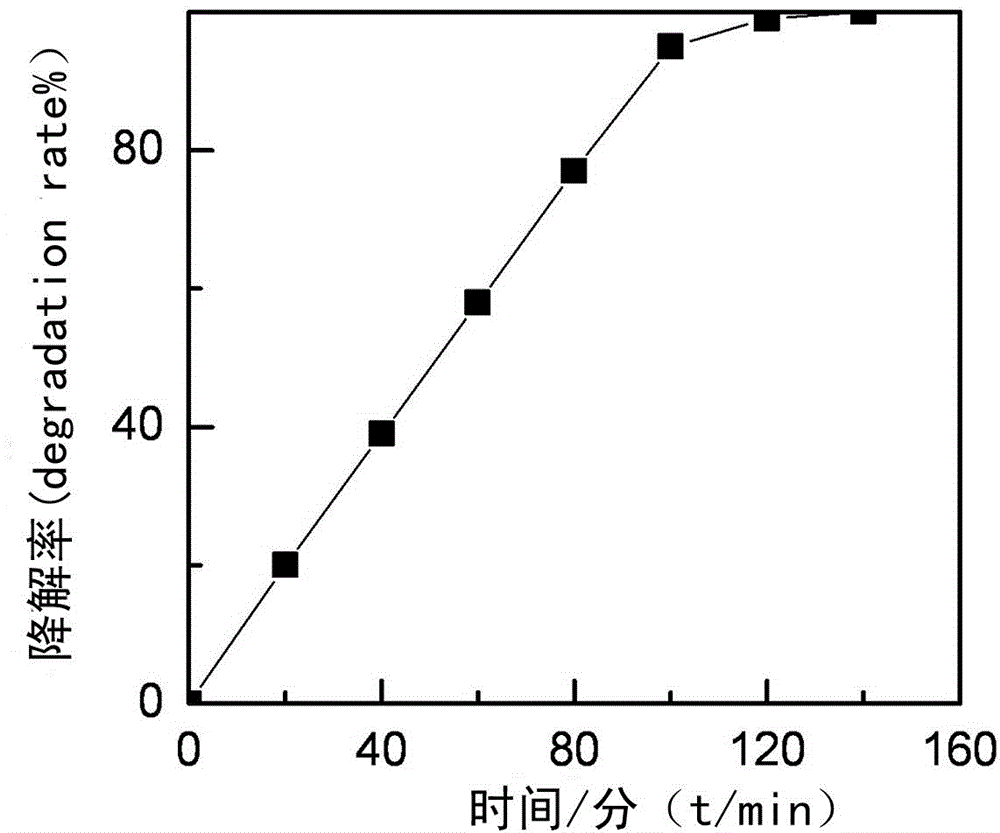

[0029] The photocatalyt...

Embodiment 2

[0032] Embodiment 2: 1.0g tin tetrachloride and 0.8g zinc chloride are dissolved in the 0.5mol / L hydrochloric acid solution of 40mL, add distilled water and dilute to 100mL, then add the hydrogen peroxide aqueous solution that the content of 1mL is 8.0%, in While stirring, add 0.5 mol / L sodium hydroxide solution dropwise to adjust the pH value to about 9.0. After the dropwise addition, raise the temperature to 50°C and control the temperature for 6 hours. The white precipitate obtained is filtered and washed, and the precipitate is dispersed into 40 mL of acetone, and added 0.1 g of oleic acid. Finally, pour the above solution into a polytetrafluoroethylene high-pressure reaction kettle, carry out solvothermal reaction at a temperature of 250°C, wash the precipitate repeatedly with deionized water, filter it with suction, dry it at a temperature of 100°C, and then empty it at 800°C The zinc stannate with a particle diameter of 30 nm was obtained by calcining under the atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com