Preparation method of pH-responsive graphene/polymer nanometer hybrid material

A nano-hybrid material, graphene technology, applied in the fields of nano-materials and biomedical engineering, can solve problems such as functional limitations, limited wide application, poor dispersion, etc., achieve good biocompatibility, wide range of raw material sources, good dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

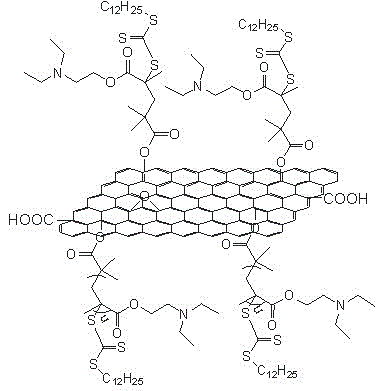

Image

Examples

Embodiment 1

[0019] The following examples are to further illustrate the present invention, but not to limit the scope of the present invention.

[0020] Weigh 1 gram of graphene oxide in a reaction kettle, disperse it with 80 grams of N,N-dimethylformamide, add 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride 12 grams of salt. Dissolve 22 grams of 2-(dodecyltrithiocarbonate)-2-methylpropionic acid in N,N-dimethylformamide and drop it into the reaction kettle at 0°C for 20 minutes After dropping, react at 5°C for 72 hours. After centrifugation at 5000 rpm for 30 minutes and drying at 30°C for 48 hours, the graphene oxide RAFT macromolecular chain transfer agent was obtained. Weigh 0.1 g of RAFT macromolecular chain transfer agent and disperse it in 2 g of dioxane, add 2 g of N,N-diethylaminoethyl methacrylate, then add 0.002 g of initiator azobisisobutyronitrile, and Vacuumize and fill with nitrogen three times, and react in an oil bath at 20° C. for 24 hours under the protec...

Embodiment 2

[0023] Weigh 1 gram of graphene oxide in a reaction kettle, disperse it with 100 grams of N,N-dimethylformamide, and then add 10 grams of chlorosulfonic acid. Dissolve 24 grams of 2-(dodecyltrithiocarbonate)-2-methylpropionic acid in N,N-dimethylformamide and drop it into the reaction kettle at 5°C for 30 minutes After dropping, react at 10°C for 60 hours. After centrifugation at 6000 rpm for 20 minutes and drying at 40 oC for 30 hours, the graphene oxide RAFT macromolecular chain transfer agent was obtained. Weigh 0.1 g of RAFT macromolecular chain transfer agent and disperse it in 3 g of anisole, add 3 g of N,N-diethylaminoethyl methacrylate, then add 0.004 g of initiator azobisisobutyronitrile, and Vacuum-inflate with nitrogen three times, and react in an oil bath at 30° C. for 20 hours under the protection of nitrogen. After the product was centrifuged at 6000 rpm for 20 minutes and dried at 40°C for 30 hours, a pH-responsive graphene oxide / polymer nano-hybrid material w...

Embodiment 3

[0026] Weigh 1 gram of graphene oxide into a reaction kettle, disperse it with 120 grams of N,N-dimethylacetamide, and then add 16 grams of thionyl chloride. Dissolve 24 grams of 2-(dodecyltrithiocarbonate)-2-methylpropionic acid in N,N-dimethylacetamide and drop it into the reaction kettle at 20°C for 35 minutes After dropping, react at 20°C for 40 hours. After centrifugation at 7000 rpm for 15 minutes and drying at 40°C for 30 hours, the graphene oxide RAFT macromolecular chain transfer agent was obtained. Weigh 0.1 g of RAFT macromolecular chain transfer agent and disperse it in 4 g of N,N-diethylformamide, add 4 g of N,N-diethylaminoethyl methacrylate, and then add the initiator azobisisobutyl Nitrile 0.006 g, through the process of evacuating and filling with nitrogen three times, and reacted in an oil bath at 40° C. for 12 hours under the protection of nitrogen. After the product was centrifuged at 7000 rpm for 15 minutes and dried at 40°C for 30 hours, a pH-responsive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com