Method for extracting lutein ester from marigold

A technology of lutein ester and marigold, applied in the direction of organic chemistry, can solve the problems of high concentration temperature, long concentration time, and prolonging the evaporation time, so as to improve quality and yield, reduce production cost, and shorten production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

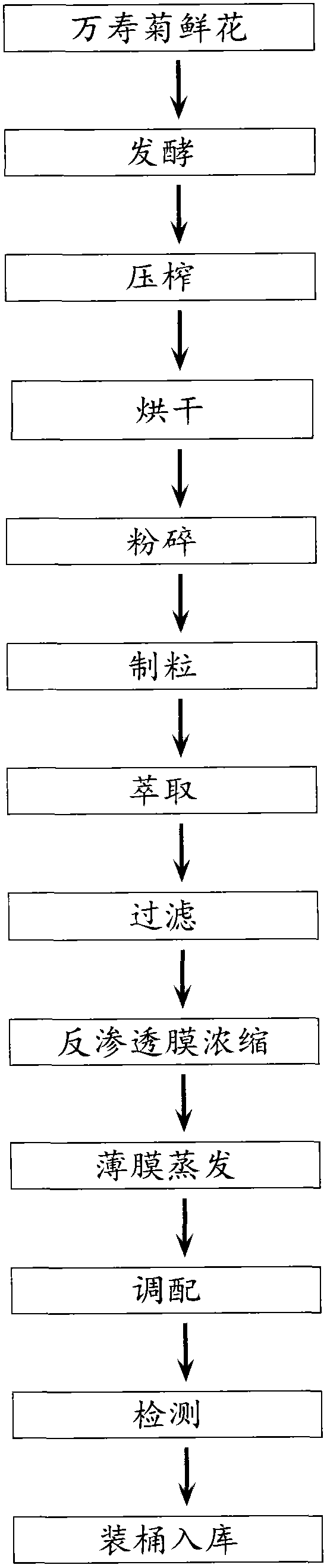

[0026] Such as figure 1 As shown, a method for extracting lutein esters from marigold includes the following steps: material selection, fermentation, squeezing, crushing, granulation, extraction, filtration, reverse osmosis membrane concentration, thin film evaporation, blending, after passing the test Packed in barrels. Pick marigolds, pick their flowers, and ferment them with lactic acid bacteria in the dark. The fermentation temperature is 25-35℃, and the fermentation time is 7-15 days. After fermentation, the marigold flowers are pressed, dried, and the initial temperature of drying is 120- 135℃, the temperature of hot and humid air after drying is 70-90℃, the dried chrysanthemum is crushed and then granulated by ring film granulator. The particle size is 3-5mm, the particle length is 12-15mm, and the water content is 7%-10%. Transfer the above-mentioned particles through a hoist and auger to a closed and stirring extractor, add isopropanol as the lutein ester leaching so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com