Double liquid phase fermentation method for preparing androstenedione by degrading plant sterol and

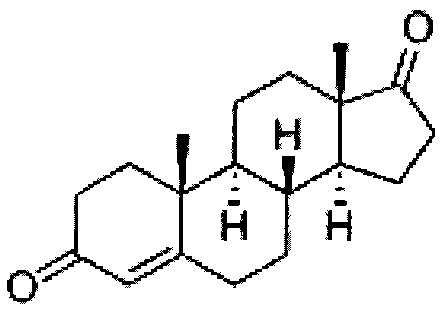

A technology for phytosterol and androstenedione, which is applied in the biological field, can solve problems such as insolubility of raw materials, and achieve the effects of increasing fermentation concentration, simplifying production process, and improving yield and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Strain: Mycobacterium sp.DE6823

[0023] Strain intake: 10%

[0024] Fermentation medium: corn starch 10%, NH 4 NO 3 0.1%, K 2 HPO 3 0.1%, aviation kerosene 0.2%, defoamer 0.002%, the concentration of sunflower oil is 20g / L, and the concentration of phytosterol is 22g / L.

[0025] Fermentation tank volume: 10L, added according to 50% fermentation broth.

[0026] Stirring speed: 160r / min

[0027] Fermentation time: 8d

[0028] pH range: 8.2-8.4

[0029] After the fermentation is completed, filter and remove the solids in the fermentation broth, add 5g / L of K 2 CO 3 , stirring, standing still, the two phases are separated, take the oil layer, add ethanol, stir well, pass through the membrane device with polypropylene membrane, the ethanol phase will flow out quickly, and the oil phase will be intercepted by the membrane due to its large viscosity and molecules. live. Concentrate the ethanol solution containing AD at a volume ratio of 10:1, add 5% activated car...

Embodiment 2

[0031] Bacterial strain: with embodiment 1

[0032] Strain intake: 8%

[0033] Fermentation medium: corn starch 8%, NH 4 NO 3 0.2%, K 2 HPO 3 0.1%, aviation kerosene 0.3%, defoamer 0.005%, the concentration of soybean oil is 20g / L, and the concentration of phytosterol is 22g / L.

[0034] Fermentation tank volume: 100L, added according to 50% fermentation broth.

[0035] Stirring speed: 300r / min

[0036] Fermentation time: 9d

[0037] pH range: 8.2~8.4

[0038] After the fermentation is completed, filter and remove the solid in the fermented liquid, add 8g / L Na 2 CO 3, stirring, standing still, the two phases are separated, take the oil layer, add acetone, stir well, pass through the membrane device with polypropylene membrane, the acetone phase will flow out quickly, and the oil phase will be intercepted by the membrane due to its large viscosity and molecules live. Concentrate the acetone solution containing AD at a volume ratio of 10:1, add 5% activated carbon to...

Embodiment 3

[0040] Bacterial strain: with embodiment 1

[0041] Strain intake: 12%

[0042] Fermentation Medium: Corn Starch 12%, NH 4 NO 3 0.1%, K 2 HPO 3 0.2%, aviation kerosene 0.5%, defoamer 0.002%, the concentration of rice bran oil is 26g / L, and the concentration of phytosterol is 22g / L.

[0043] Fermentation tank volume: 100L, added according to 50% fermentation liquid.

[0044] Stirring speed: 250r / min

[0045] Fermentation time: 9d

[0046] pH range: 8.2~8.4

[0047] After the fermentation is completed, filter and remove the solid in the fermented liquid, add 8g / L of K 2 CO 3 , stirring, standing still, two-phase separation, take the oil layer, add isobutanol, stir well, pass through the membrane device with polypropylene membrane, the isobutanol phase will flow out quickly, and the oil phase will flow out due to the viscosity and larger molecules , will be intercepted by the membrane. Concentrate the isobutanol solution containing AD at a volume ratio of 10:1, add 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com