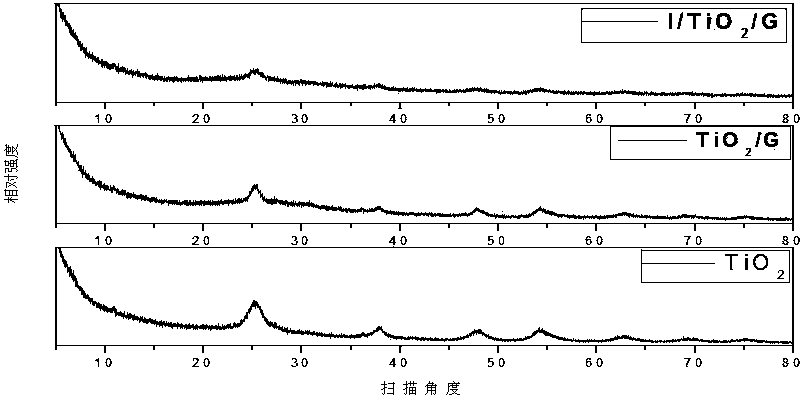

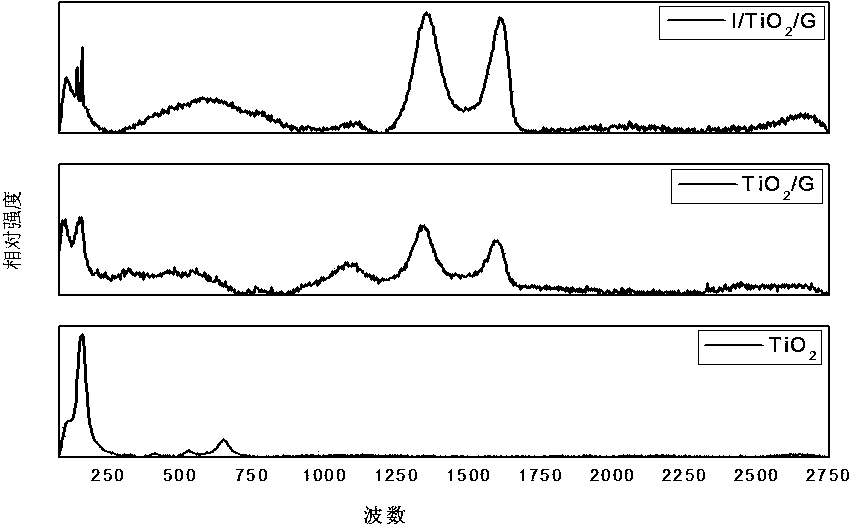

Preparation method of iodine-doped titanium dioxide-graphene composite photocatalyst

A technology of graphene composite and titanium dioxide, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of insufficient stability of catalytic activity and insufficient catalytic activity, so as to improve photocatalysis Activity, expanding the spectral response range, promoting the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of Graphene Oxide

[0021] Assemble a 250mL reaction flask in an ice-water bath, add 60mL concentrated H 2 SO 4 , add 2g graphite powder and 1gNaNO under stirring 3 The solid mixture, then add 6gKMnO 4 , control the reaction temperature not to exceed 20°C, stir and react for a period of time, then raise the temperature to about 35°C, continue stirring for 30 minutes, then slowly add a certain amount of deionized water, continue stirring for 20 minutes, and add an appropriate amount of hydrogen peroxide to reduce the residual oxidant to make the solution Turn golden yellow, filter while hot, and wash with 5% HCl solution and deionized water for 3 to 5 times, then place the filtrate in a vacuum oven at 60°C to fully dry, and store for future use.

Embodiment 2

[0023] Preparation of Titanium Dioxide Photocatalyst

[0024] Take 2mlTiCl 4 Add dropwise to 310ml of aqueous solution, stir at room temperature for hydrolysis to obtain a white sol, transfer it to a high-pressure reactor with polytetrafluoroethylene, and conduct a hydrothermal reaction at 100°C for 24 hours. After naturally cooling to room temperature, take out the reactant , centrifuged, washed, and vacuum-dried at 60°C to obtain a white powder.

Embodiment 3

[0026] Preparation of Titanium Dioxide-Graphene Composite Photocatalyst

[0027] Weigh 0.15g of the prepared graphene oxide and ultrasonically disperse it in 310ml of distilled water for 15min, centrifuge at 6000rpm for 5min, transfer to the refrigerator (5°C) for 1h to obtain an ice-brown solution, then take 2ml of TiCl 4 Add dropwise to the ice solution and stir at room temperature for hydrolysis to obtain a light yellow sol, transfer it to a high-pressure reactor with polytetrafluoroethylene, and conduct a hydrothermal reaction at 100°C for 24 hours. After naturally cooling to room temperature, take out the reactant , centrifuged, washed, and vacuum-dried at 60°C to obtain a gray powder, whose scanning electron microscope picture is figure 1 on the left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com