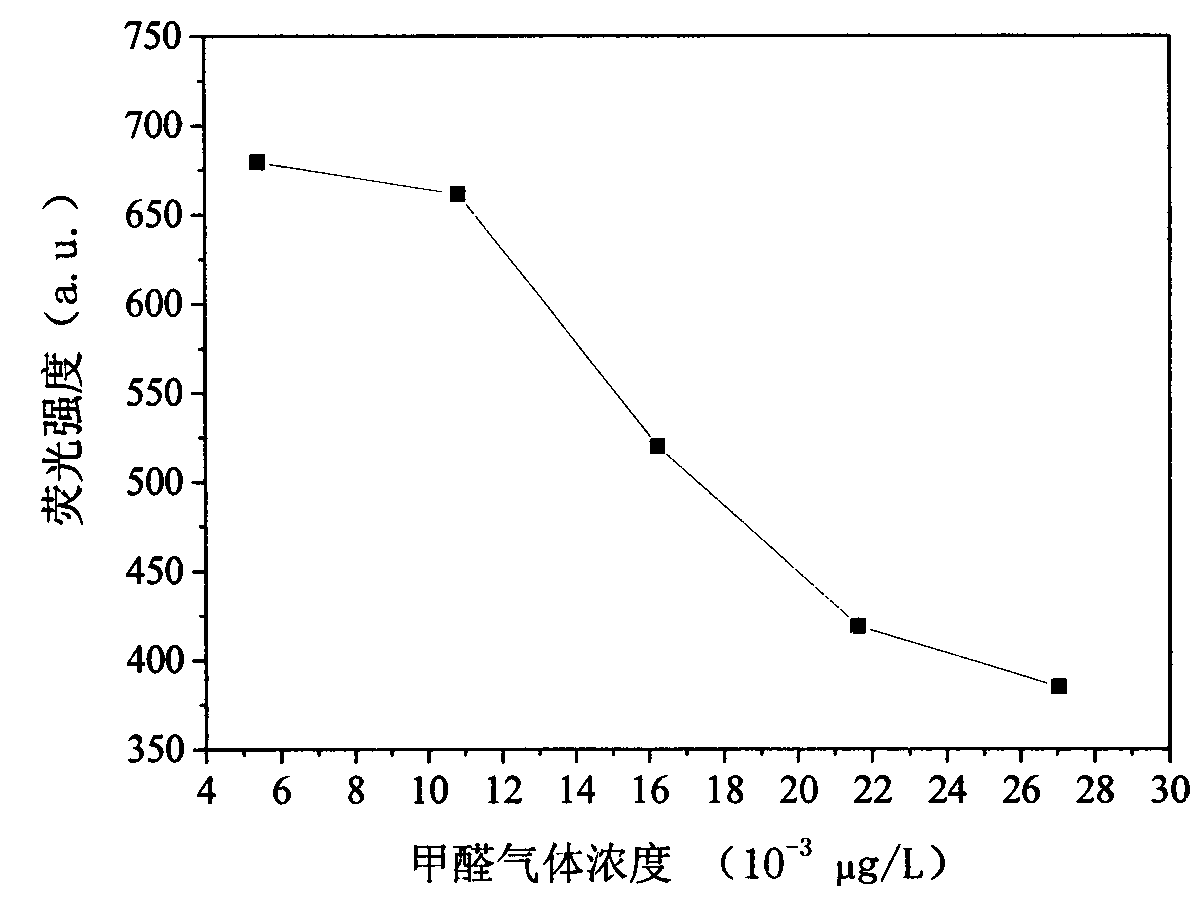

Preparation method of high-sensitivity formaldehyde gas sensor

A formaldehyde gas, high-sensitivity technology, applied in the field of preparation of high-sensitivity formaldehyde gas sensors, can solve problems such as pollution, and achieve the effects of high sensitivity, good stability and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019]2. Preparation of L-cysteine-wrapped quantum dots: first dissolve 0.1-2.0g cadmium chloride with 10-100ml ultrapure water, then dissolve 0.1-2.0g L-cysteine with 10-100ml ultrapure water (L-cys), and then put the three-necked bottle with magnets into the heat-collecting constant temperature heating stirrer (DF-101S), and pass nitrogen gas under ice water conditions to ensure that all the air in the three-necked bottle is discharged. Add the dissolved cadmium chloride solution into the three-necked bottle, add 10-200ml ultrapure water at the same time, turn on the stirrer to stir, and pass nitrogen gas for 10-100min; after that, add the dissolved L-cys solution to the three-necked bottle, and add 10-200ml of ultra-pure water, adjust the pH to 3-14 with 0.5-4mol / L NaOH (this process, the reaction solution changes from clear to milky white and then becomes clear), similarly, pass nitrogen gas for 10-100min, after that, add to the reaction solution NaHTe (1-6ml) solution p...

Embodiment 1

[0025] 1. Preparation of NaHTe precursor: Take 0.04g of sodium borohydride, 0.9g of tellurium powder and 3ml of water, react in a syringe, leave it at room temperature for 5 hours and take it out. The solution turns from black to light red or purple.

[0026] 2. Preparation of quantum dots wrapped by L-cysteine: first dissolve 0.4g cadmium chloride with 50ml ultrapure water, dissolve 0.4g L-cysteine (L-cys) with 25ml ultrapure water, and then Put the three-necked bottle with magnets into the heat-collecting constant temperature heating stirrer (DF-101S), pass nitrogen gas under ice water conditions to ensure that all the air in the three-necked bottle is exhausted, and then add dissolved chlorine into the three-necked bottle Cadmium chloride solution, add 125ml of ultrapure water at the same time, turn on the stirrer to stir, and pass nitrogen gas for 20min; after that, add the dissolved L-cys solution into the three-necked flask, add 140ml of ultrapure water at the same time...

Embodiment 2

[0031] 1. Preparation of NaHTe precursor: Take 0.03g of sodium borohydride, 0.9g of tellurium powder and 3ml of water, react in a syringe, place it at room temperature for 5 hours and take it out. The solution turns from black to light red or purple.

[0032] 2. Preparation of quantum dots wrapped by L-cysteine: first dissolve 0.4g cadmium chloride with 50ml ultrapure water, dissolve 0.4g L-cysteine (L-cys) with 25ml ultrapure water, and then Put the three-necked bottle with magnets into the heat-collecting constant temperature heating stirrer (DF-101S), pass nitrogen gas under ice water conditions to ensure that all the air in the three-necked bottle is exhausted, and then add dissolved chlorine into the three-necked bottle Cadmium chloride solution, add 125ml of ultrapure water at the same time, turn on the stirrer to stir, and pass nitrogen gas for 20min; after that, add the dissolved L-cys solution into the three-necked flask, add 140ml of ultrapure water at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com