Hydrogen storage electrode alloy for Ni-MH secondary battery and preparation method thereof

A secondary battery and electrode alloy technology, which is applied in the field of hydrogen storage alloy materials, can solve the problems of poor electrochemical cycle stability of alloys and difficulty in meeting the requirements of Ni-MH batteries, and achieves easy large-scale industrial production and simple preparation methods , tissue and structural homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the high-capacity, long-life hydrogen storage electrode alloy for Ni-MH battery of the present invention comprises the following steps:

[0029] A. Carry out weighing and proportioning according to the designed chemical formula atomic ratio. Since the melting point of magnesium and rare earth elements is relatively low and easy to volatilize, the burning loss should be increased by 5%-10% in the ratio, among which 8% for magnesium and 5% for rare earth are better;

[0030] B. Melting is carried out by induction heating, and the prepared raw materials are placed in a magnesia crucible. Except for magnesium, which is placed on the top layer of the crucible, other materials are added to the crucible in no particular order. After covering the furnace cover, vacuumize to 1×10 -2 -5×10 -5 Pa, and then filled with 0.01-0.1 MPa inert protective gas, that is, helium or argon + helium mixed gas, the volume ratio of the mixed gas is about 1:1; the mel...

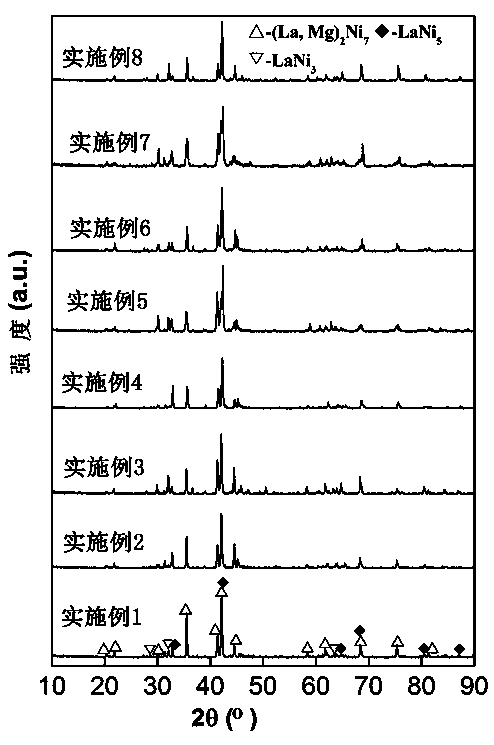

Embodiment 1

[0035] Example 1: La 0.6 SM 0.15 Mg 0.22 Ti 0.03 Ni 3.4 Al 0.1 Si 0.07

Embodiment 2

[0036] Example 2: La 0.6 Nd 0.15 Mg 0.22 Ti 0.03 Ni 3.4 Al 0.1 Si 0.07

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com