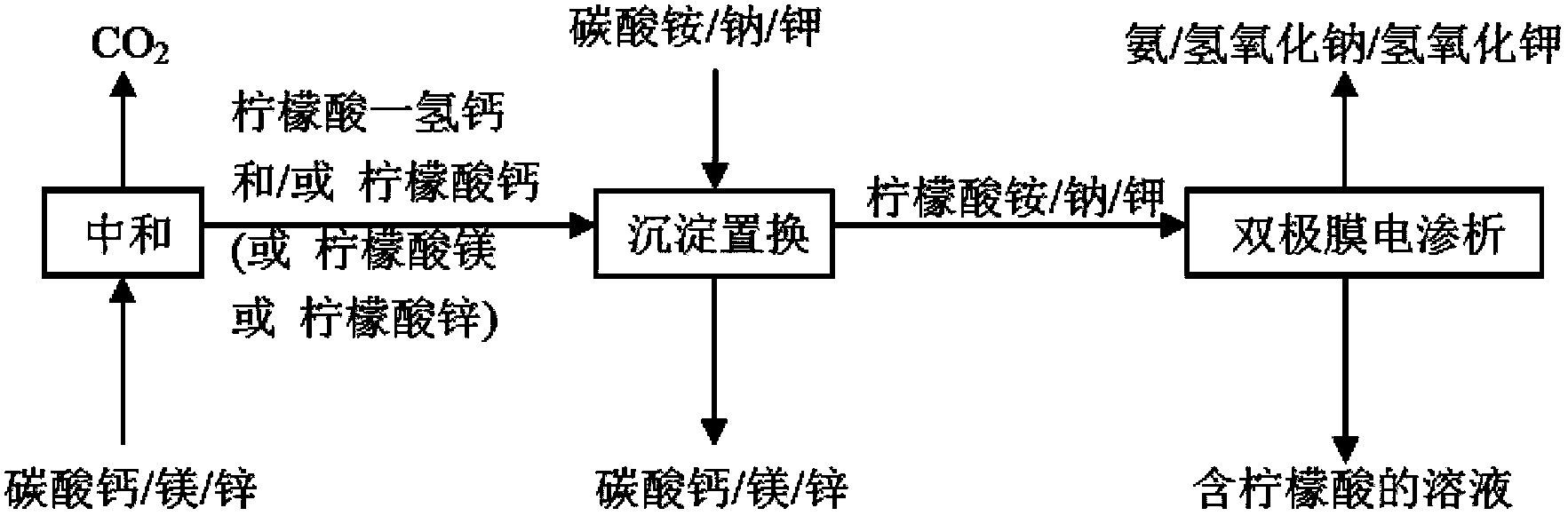

Method for cleanly producing citric acid by coupling calcium salt method with precipitation displacement

A technology of clean production and citric acid, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve problems such as difficult to eliminate calcium sulfate, and achieve the effect of overcoming calcium sulfate waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

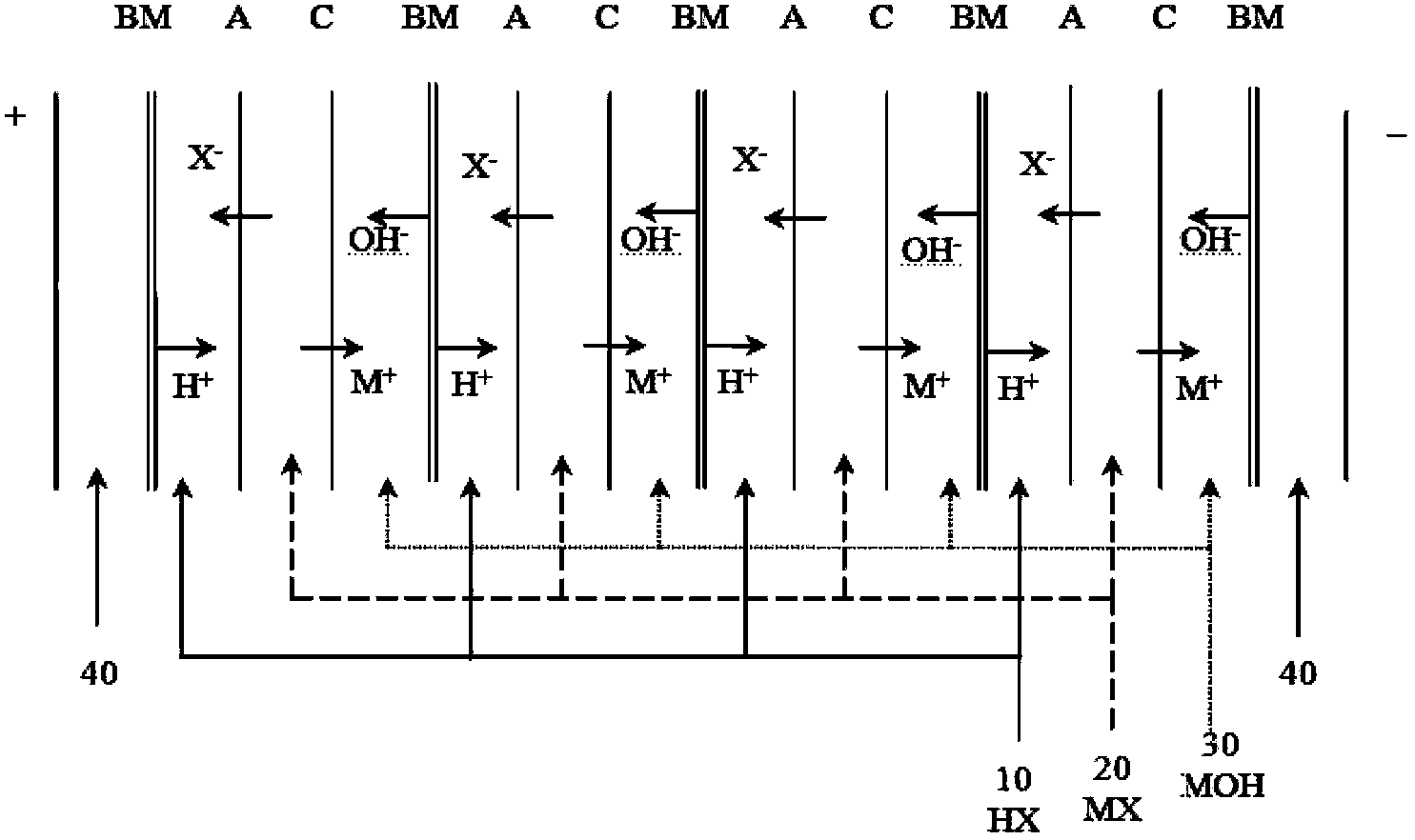

[0061] The specific method for the preparation of ammonium carbonate, sodium carbonate or potassium carbonate is: the CO containing 2 The gas is passed into the alkali chamber of the bipolar membrane electrodialyzer in step 2), or the regenerated NH obtained in step 2) 3 (ammonia water, liquid ammonia or ammonia gas), sodium hydroxide solution or potassium hydroxide solution and citric acid neutralization step 2 The gas is passed into the absorption container at the same time to obtain ammonium carbonate, sodium carbonate or potassium carbonate solution; the obtained ammonium carbonate, sodium carbonate or potassium carbonate solution can be further evaporated and concentrated to obtain ammonium carbonate, sodium carbonate or potassium carbonate solid.

[0062] The obtained ammonium carbonate, sodium carbonate or potassium carbonate solution or solid can be used in step 1) precipitation replacement reaction.

[0063]In the implementation of step 2), the solution containing am...

Embodiment 1

[0090]Step 1) Precipitation replacement reaction:

[0091] Take 841g of solid calcium citrate from the citric acid workshop of COFCO Biochemical (Anhui) Co., Ltd., add it to 1.0L of water, stir properly to make it a suspension, and add 5.0mol / L ammonium carbonate solution to the In the suspension of calcium citrate, use the offline method to measure the pH of the system during the reaction. When the pH is higher than 10.0, stop feeding the ammonium carbonate solution, keep stirring to make it react completely, and consume 1.02L of the ammonium carbonate solution in total; filter Obtain 2.0 L of ammonium citrate-containing solution of 512 g of calcium carbonate solids and 308.0 g / L of citric acid concentration.

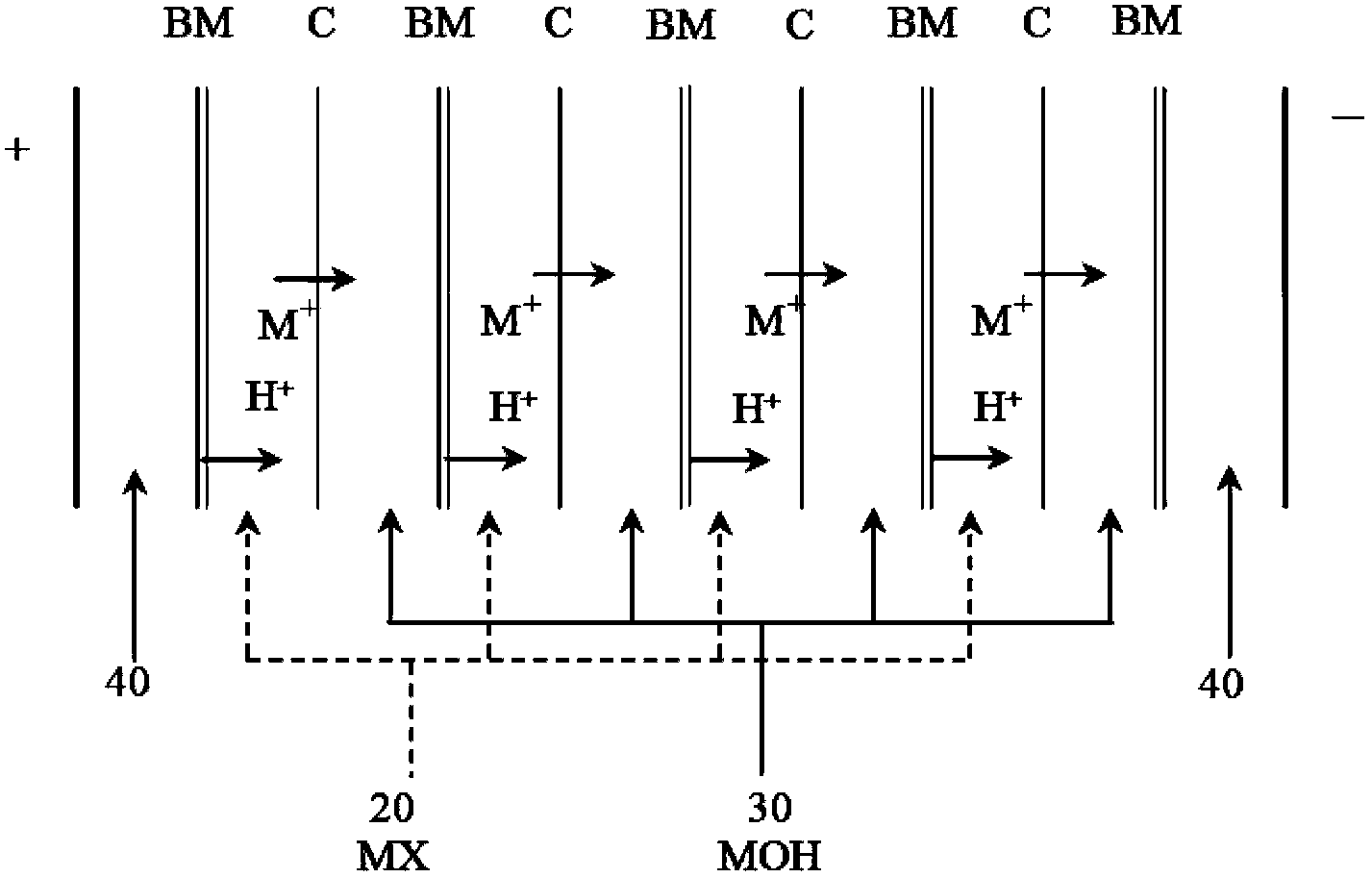

[0092] Step 2) Bipolar Membrane Electrodialysis:

[0093] The bipolar membrane electrodialyzer is a "salt-alkali" two-chamber bipolar membrane electrodialyzer with one stage and one independent operation, and the liquid flow direction in adjacent compartments adopts a...

Embodiment 2

[0097] Step 1) Precipitation replacement reaction:

[0098] Take the calcium monohydrogen citrate solid from the citric acid workshop of COFCO Biochemical (Anhui) Co., Ltd. and add it to 1.02L of 3.9mol / L sodium carbonate solution in batches, stir properly, and use an online pH measuring device to measure the system during the replacement reaction. pH change, when the calcium monohydrogen citrate solid addition was 551g, the pH of the system was lower than 7.0, stop adding the monohydrogen calcium citrate solid, keep stirring to make it fully carry out the precipitation replacement reaction; filter to obtain calcium carbonate solid 241g and 1.01L of a solution containing sodium citrate with a citric acid concentration of 450g / L.

[0099] Step 2) Bipolar Membrane Electrodialysis:

[0100] Bipolar membrane electrodialysis is the same as Step 2 of Example 1). The solution 1.0L containing sodium citrate obtained by step 1) is passed into the salt chamber of the bipolar membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com