High ferulic acid stress resistance clostridium beijerinckii and application thereof

A technology of Clostridium beijerinckii and ferulic acid, which is applied in the direction of bacteria, microorganisms, biochemical equipment and methods, can solve the problems of production stoppage of bio-butanol manufacturers, and achieve high butanol production, strong stress resistance, and repeated good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example illustrates the first step of plasma mutagenesis of the original strain of Clostridium beijerinckii.

[0032] The method for the first step plasma mutagenesis of the original bacterial strain of Clostridium beijerinckii is as follows:

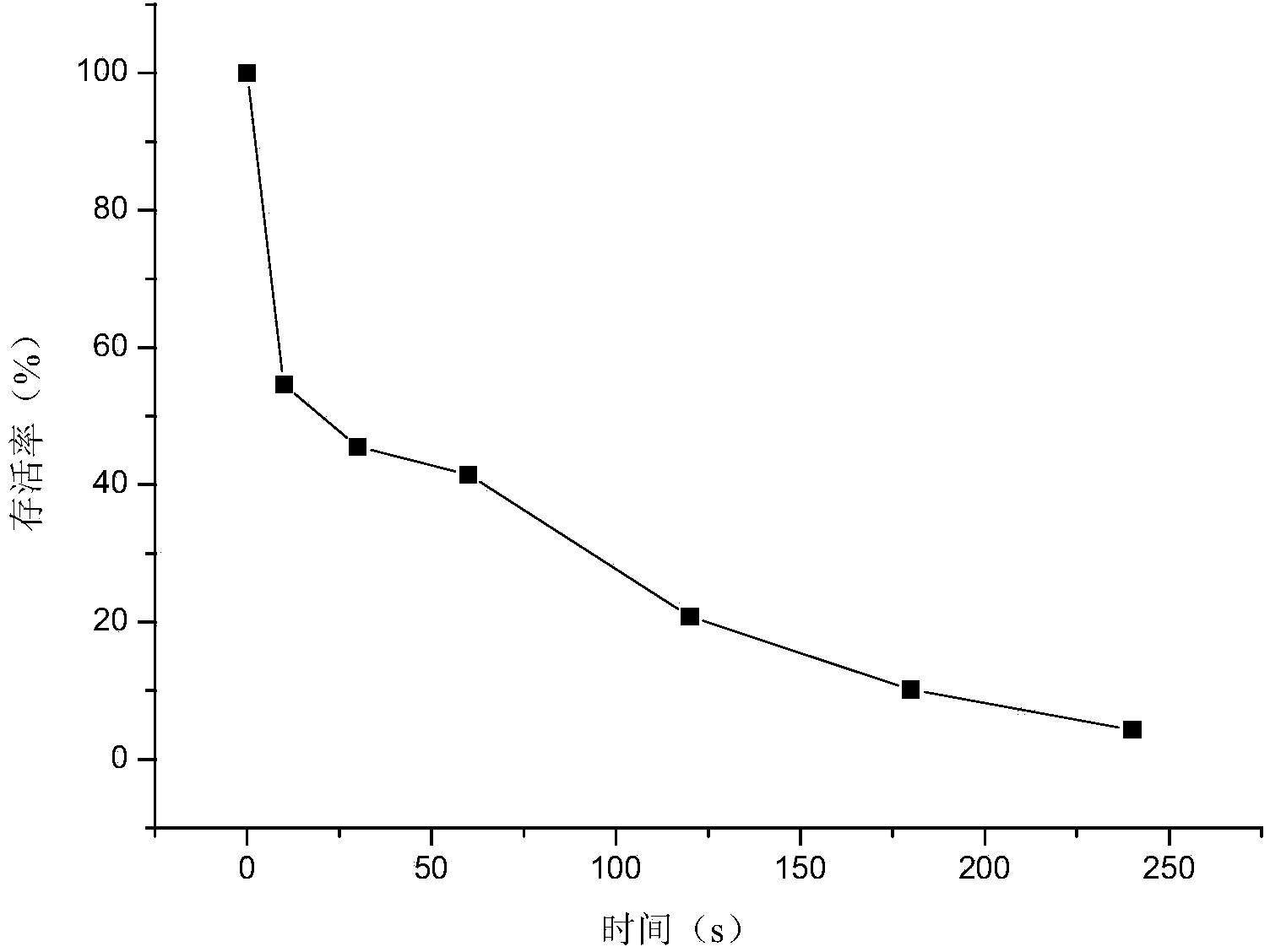

[0033] The original strain of Clostridium beijerinckii NCIMB8052 was activated and cultured at a culture temperature of 33-37°C, the volume of 50ml Schott anaerobic bottle was 15-20ml, filled with nitrogen for 3 minutes, and the culture time was 12-18 hours to obtain a vigorously growing bacterial liquid; take fresh Cultured cells were diluted to cell concentration OD 600 =1~1.5, drop on the sterilized and cooled slide, dry with sterile air; use helium as the discharge gas, 100W as the radio frequency power, 10SLM as the gas flow rate, and 10~1800s as the irradiation time Plasma mutagenesis was performed on the bacterial strain, and after the mutagenesis, the bacterial film on the carrier was eluted, and the survival rate w...

Embodiment 2

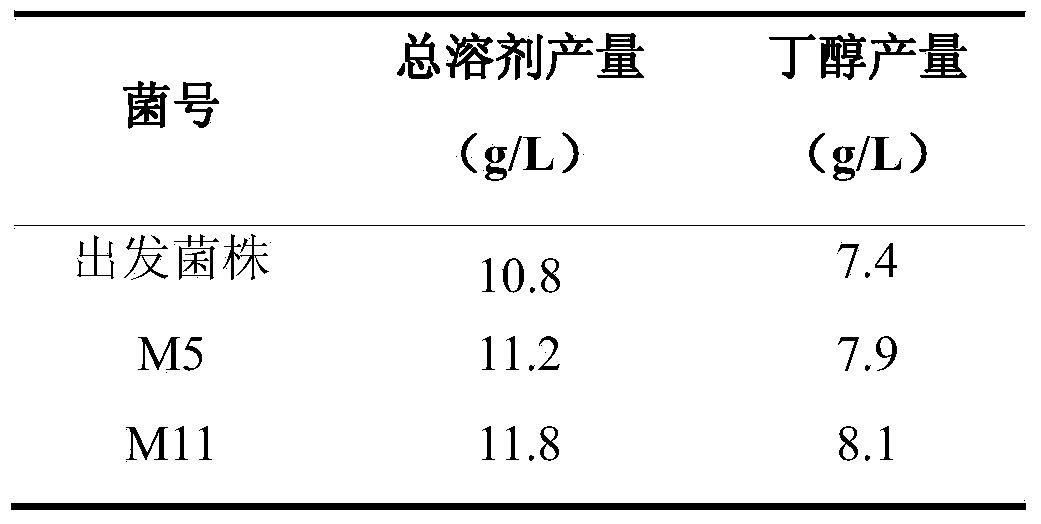

[0035] This example illustrates the method for screening good Clostridium beijerinckii.

[0036] Wherein, the medium formula used (% is mass percentage):

[0037] (1) Solid plate medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dihydrogen phosphate Potassium 0.1%, ferrous sulfate heptahydrate 0.01%, agar 1.5%, pH6.

[0038] (2) Resazurin plate medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, phosphoric acid Dipotassium hydrogen 0.1%, ferrous sulfate heptahydrate 0.01%, agar 1.5%, resazurin 0.002%, ferulic acid 0.5%, pH6.

[0039] (3) Seed medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dipot...

Embodiment 3

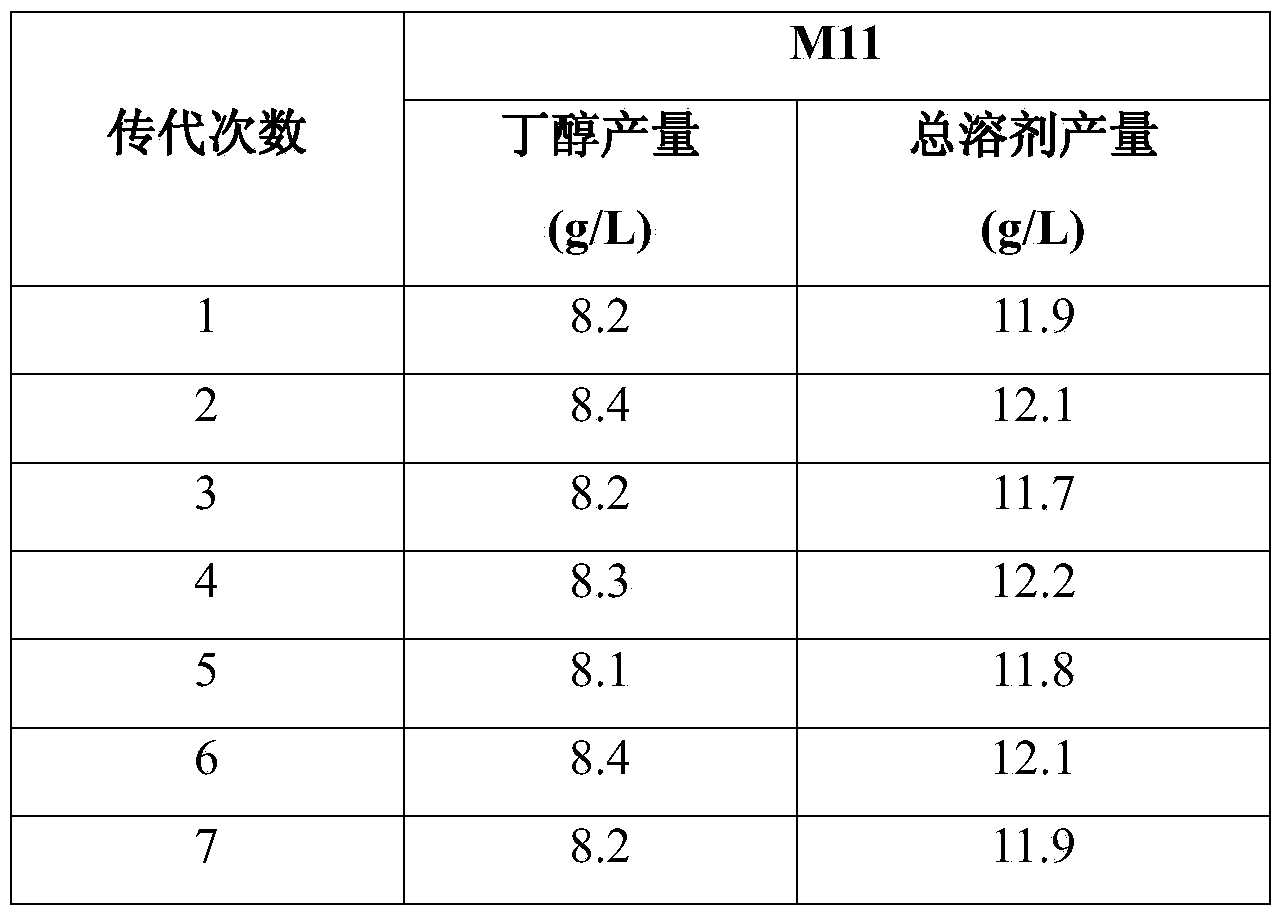

[0050] This example illustrates the passage stability of the mutant strain M11.

[0051] In the fermentation medium with glucose as the carbon source, the passage stability of the mutant strain M11 was detected, and the results of the passage fermentation test of the strain M11 are shown in Table 2:

[0052] Table 2

[0053]

[0054] From the experimental results, it can be seen that after 7 consecutive passages, the total solvent production and butanol production of the two mutant strains are relatively stable, and they have good passage stability, and can be used as production strains for further research and development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com