Method and application for preparing ultra-thin copper seed layer by processing surfaces of hydrogen plasmas

A copper seed layer, hydrogen plasma technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor adhesion, multi-impurities in thin films, etc., to increase adhesion, reduce impurity content, The effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A remote hydrogen plasma surface treatment was performed after the ALD deposition of an ultra-thin copper seed layer.

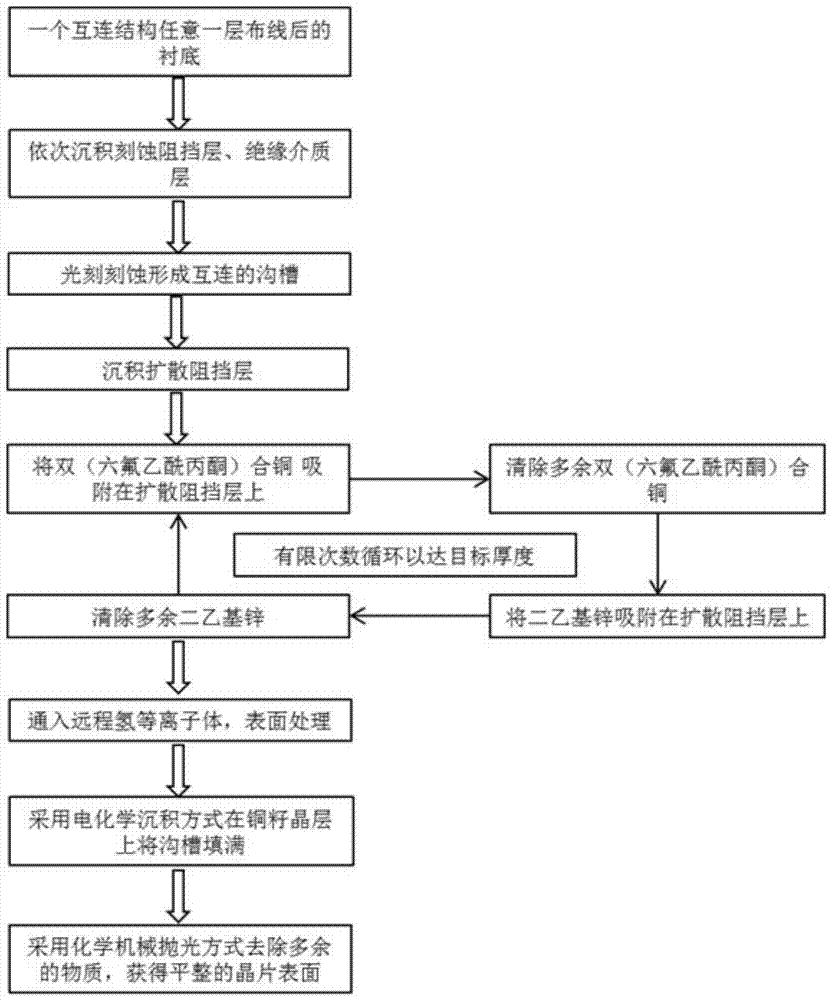

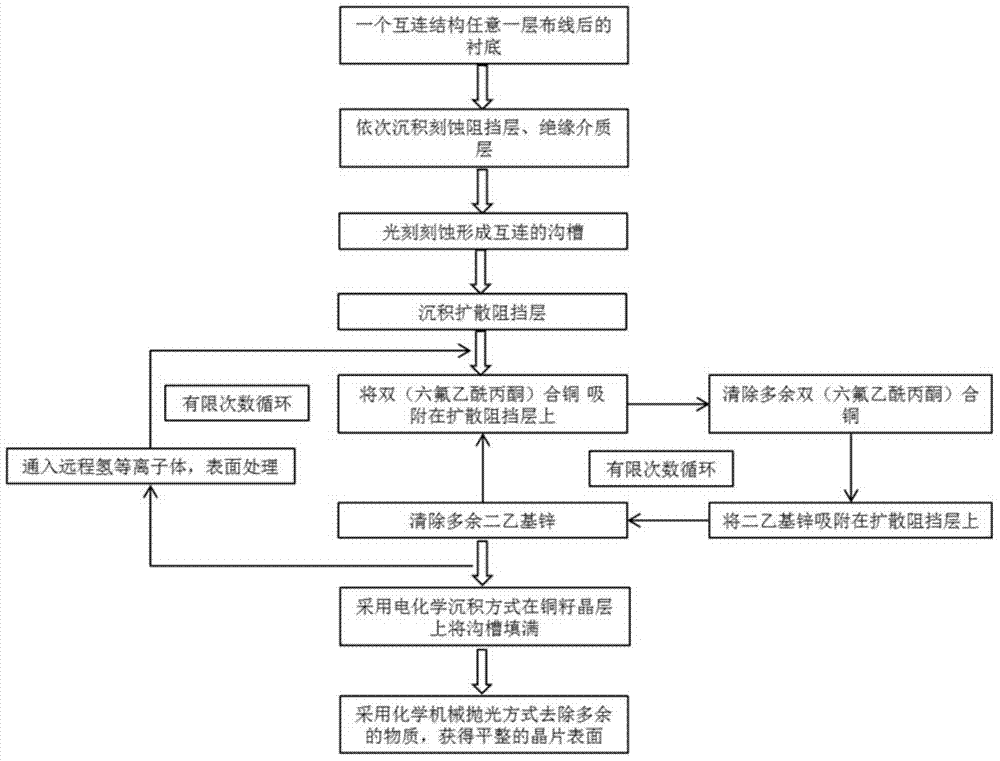

[0050] The copper interconnect structure is prepared as follows:

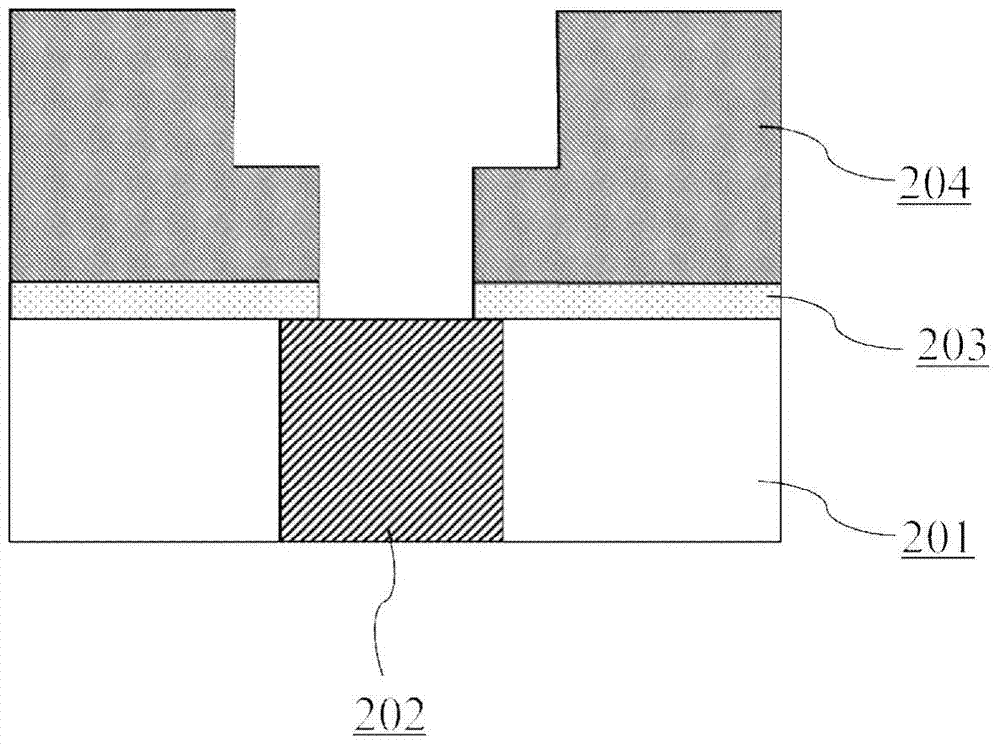

[0051] Step A. If image 3 As shown, on the substrates 201 and 202 after any layer of an interconnection structure is wired, an etch stop layer 203 is deposited first, and then an insulating dielectric layer 204 is deposited.

[0052] The material of the insulating dielectric layer 204 is silicon dioxide SiO 2 , the material of the etch stop layer 203 is silicon nitride.

[0053] Step B. If image 3 As shown, the interconnected trenches are formed by photolithographic etching using a standard dual damascene process flow.

[0054] Step C. If Figure 4 As shown, the Ta / TaN diffusion barrier layer 205 is deposited by magnetron sputtering.

[0055] Step D. If Figure 5 As shown, a high-quality ultra-thin copper seed layer 206 is prepared on the barrier layer, and the specific steps a...

Embodiment 2

[0069] Remote hydrogen plasma surface treatment during ALD deposition of ultrathin copper seed layers.

[0070] The copper interconnect structure is prepared as follows:

[0071] Step A. If image 3 As shown, on the substrates 201 and 202 after any layer of an interconnection structure is wired, an etch stop layer 203 is deposited first, and then an insulating dielectric layer 204 is deposited.

[0072] The material of the insulating dielectric layer 204 is fluorinated silicon dioxide SiOF, and the material of the etching stop layer 203 is silicon nitride.

[0073] Step B. If image 3 As shown, the interconnected trenches are formed by photolithographic etching using a standard dual damascene process flow.

[0074] Step C. If Figure 4 As shown, the Ta / TaN diffusion barrier layer 205 is deposited by magnetron sputtering or the like.

[0075] Step D. If Figure 5 As shown, an ultra-thin copper seed layer 206 is prepared on the barrier layer, and the specific steps are as ...

Embodiment 3

[0087] Remote hydrogen plasma surface treatment during ALD deposition of ultrathin copper seed layers.

[0088] The copper interconnect structure is prepared as follows:

[0089] Step A. If image 3 As shown, on the substrates 201 and 202 after any layer of an interconnection structure is wired, an etch stop layer 203 is deposited first, and then an insulating dielectric layer 204 is deposited.

[0090] The material of the insulating dielectric layer 201 is porous hydrocarbon-doped silicon oxide SiCO:H, and the material of the etching stopper layer is silicon nitride.

[0091] Step B. If image 3 As shown, photolithographic etching forms interconnected trenches 210 .

[0092] Step C. If Figure 4 As shown, the Ta / TaN diffusion barrier layer 205 is deposited by magnetron sputtering.

[0093] Step D. If Figure 5 As shown, an ultra-thin copper seed layer 206 is prepared on the barrier layer, and the specific steps are as follows.

[0094]The precursors for depositing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com