Thermus and application thereof

A technology for blackening caused by Thermus and water pipes, which is applied in the field of microorganisms for removing sulfur-containing substances, can solve the problems of increasing treatment costs and increasing energy consumption, and achieves the effects of shortening the start-up period, short adaptation period and good treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

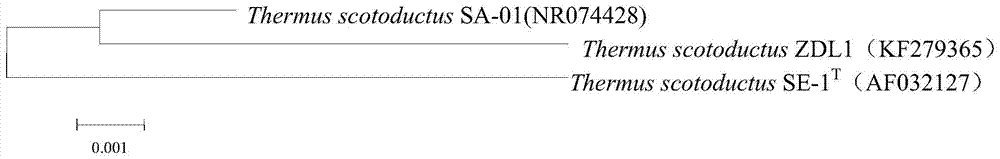

Embodiment 1

[0040] The DNA of the target strain was extracted and purified by the automatic magnetic bead nucleic acid extractor Smart LabAssist-16 and the corresponding environmental sample DNA extraction and purification kit, respectively, and PCR amplification was carried out with bacterial general primers F16S-27 and R16S-1492. The primer sequences were respectively for:

[0041] F16S-27 (5`-AGAGTTTGATCCTGGCTCAG-3`)

[0042] R16S-1492 (5`-CGGTTACCTTGTTACGACTTC-3`)

[0043] The PCR reaction conditions were set as follows: 94°C pre-denaturation for 5 min; followed by 94°C denaturation for 30 sec, 56°C annealing for 30 sec, 72°C extension for 90 sec, and 25 cycles; then 72°C extension for 10 min; and finally 4°C for 10 min. The PCR product was then ligated to the PMD-19T vector, and then transformed into Escherichia coli DH5α competent cells. Spread 50 μl of transformed competent cells on LB medium containing galactoside, isopropyl-β-d-thiogalactoside and ampicillin. After culturing ...

Embodiment 2

[0044] Example 2: Treatment of waste gas with thermus bacterium agent

[0045] Centrifuge the fermented Thermus agrigenans ZDL1 and resuspend the bacterial agent obtained by nutrient solution in a bioreactor, feed the gas containing sulfur and malodorous substances, and purify the sulfur-containing substances in the exhaust gas with Thermus agrigenans ZDL1 Malodorous substances, thermus bacteria agent volume is 1m 3 , the content of ZDL1 of Thermus agrigenus in water pipes was 10 10 CFU / ml (悬浮液) , the total concentration of sulfide is 150ppm, and the gas flow rate is 10m 3 / h, and the purification temperature is 60°C.

[0046] The composition of described nutrient solution is: beef powder 5.0g, KH 2 PO 4 2.0g, KNO 3 2.0g, NH 4 Cl0.5g, MgCl 2 ·6H 2 O0.5g, FeCl 2 ·7H 2 O0.01g, NaHCO 3 1.0g, 1000ml of water, pH 6.5; track and detect the degradation ability of sulfur-containing malodorous substances.

[0047] The present invention adopts gas chromatography to track an...

Embodiment 3

[0049] Example 3: A microbial active filler for removing sulfur-containing substances and purifying medium / high temperature sulfur-containing waste gas

[0050] The porous material is attached with a suspension of Thermus aeruginosa ZDL1;

[0051] The porous material is granular activated carbon;

[0052] The density of the porous material is 0.8kg / m 3 , the porosity is 86%, the particle size is 20mm;

[0053] The Thermus aeruginosa ZDL1 is attached to the granular activated carbon in the form of bacterial suspension;

[0054] The mass ratio of the Thermus aeruginosa ZDL1 bacterial suspension to the granular activated carbon is 100:10;

[0055] The cell concentration of Thermus aeruginosa ZDL1 in the microbial active filler is 5.0×10 6 CFU / g (活性填料) .

[0056] The preparation steps of the microbial active filler are as follows:

[0057] (1) Slope culture: culture and prepare the slant strain of Thermus aeruginosa ZDL1;

[0058] The slant medium consists of: beef powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com