Novel purification process for zinc hydrometallurgy solution

A technology of hydrometallurgy and solution purification, which is applied in the direction of photographic process, photographic auxiliary process, and improvement of process efficiency. It can solve the problems of disturbing the adsorption surface area of activated carbon, high processing cost, and large usage, so as to increase investment and recovery. Cost, reduction of impurity content, effect of consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

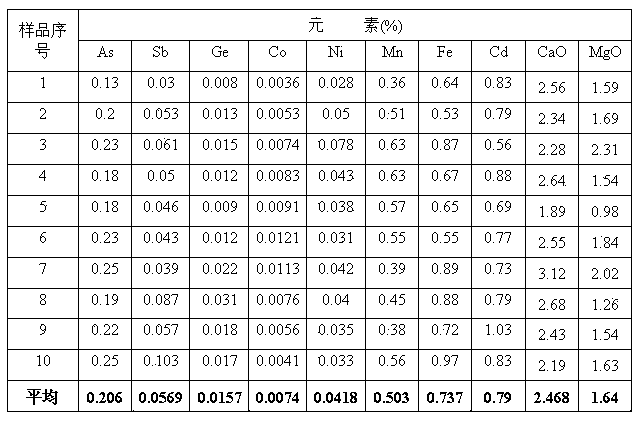

Examples

Embodiment 1

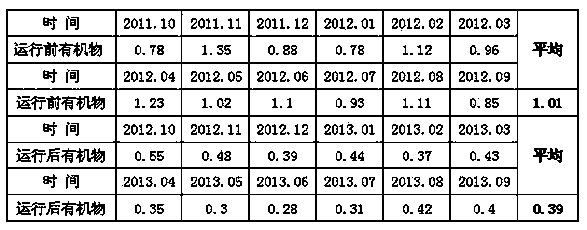

[0020] A zinc smelter has an annual output of 200,000 tons of precipitated zinc. The solution is purified by adding zinc powder and xanthate. Since xanthate itself is an organic substance, it is very difficult to control the organic substance in this plant.

[0021] Adopt novel hydrometallurgy solution purification process of the present invention, process is as follows:

[0022] Step 1: Press filter the purified liquid containing more xanthate in conventional zinc hydrometallurgy, open the filter residue, and send the filtrate to the next purification process;

[0023] Step 2: Add wood-encapsulated powdered activated carbon with a particle size of 10-60 μm to the filtrate produced in the first step to remove impurities. The amount added is calculated according to the volume of the filtrate at a ratio of 0.3-0.5 g / l. The addition method is one-time Adding, the temperature of the filtrate is controlled at 45°C, stirring after adding, the stirring time is 40-50min, the liquid af...

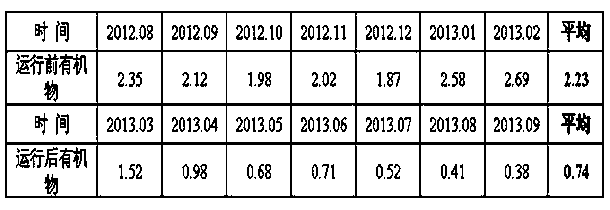

Embodiment 2

[0034] A zinc smelter has an annual output of 100,000 tons of precipitated zinc. The smelting process adopts the direct leaching process with atmospheric pressure and oxygen enrichment. High content, difficult to control.

[0035] Adopt novel hydrometallurgy solution purification process of the present invention, process is as follows:

[0036] Step 1: Press filter the purified liquid containing more residual beneficiation agents in conventional zinc hydrometallurgy, open the filter residue, and send the filtrate to the next purification process;

[0037] Step 2: Add wood-encapsulated powdered activated carbon with a particle size of 10-60 μm to the filtrate produced in the first step to remove impurities. The amount added is calculated according to the volume of the filtrate at a ratio of 0.1-0.5 g / l. The addition method is continuous A small amount is added evenly, the temperature of the filtrate is controlled at 55°C, and continuous stirring is carried out after addition.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com