Preparation method for mould cheese

A cheese and mold technology, which is applied in the field of mold cheese preparation, can solve the problems of long maturation period, spicy cheese and other difficult stimulating flavors, and achieve the effect of easy flavor and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

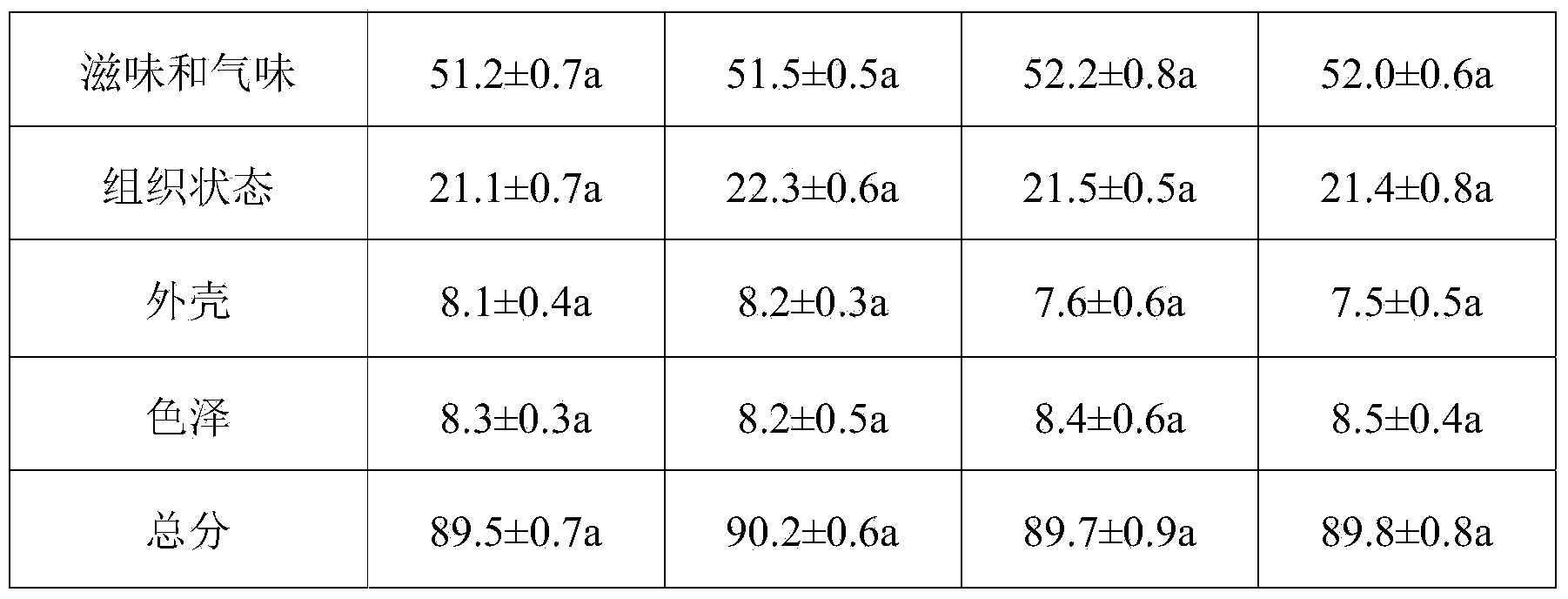

Embodiment 1

[0068] (1) Standardize the qualified raw milk so that the mass ratio of protein to fat is 0.8;

[0069] (2) Pasteurization, the sterilization condition is 72°C / 15s, cooled to 32°C;

[0070] (3) Add Flora Danica starter, acidify and ferment at 10U / 100L, and add Monascus culture solution at the same time (so that the number of Monascus bacteria in the raw milk is 10 7 cfu / L), with the pH dropping to 6.4 as the end point of acidification fermentation;

[0071] (4) Add 0.01% (w / v) of red yeast rice flour and stir thoroughly;

[0072] (5) Add calf rennet, stir for 10 minutes and let stand, curd for 30 minutes and cut the curd into 2cm 3 small pieces, stirred slowly for 15 minutes;

[0073] (6) Discharge 30% whey, when the pH value drops to 5.4, the whey discharge ends, add 2% salt, put into the mold, turn over once at 1h, 5h, 19h, and then stand at 18°C for 12h;

[0074] (7) Take the curd block out of the mold and let it stand for 10 minutes;

[0075] (8) Put 1000g of curd ...

Embodiment 2

[0079] (1) Standardize the qualified raw milk so that the mass ratio of protein to fat is 0.9;

[0080] (2) Pasteurization, the sterilization condition is 68°C / 30s, cooled to 28°C;

[0081] (3) Add MA14 starter, acidify and ferment at 140U / 1000L, and add Monascus culture medium 10 8 cfu / L; when the pH drops to 6.3 as the end point of acidification fermentation;

[0082] (4) Add 0.15% (w / v) of red yeast rice flour and stir thoroughly;

[0083] (5) Add microbial rennet, stir for 5 minutes and let it stand, curd after 25 minutes and cut the curd into 1.8cm 3 small pieces, stirred slowly for 30min;

[0084] (6) Discharge 40% whey, when the pH value drops to 5.6, the whey discharge ends, add 2.5% salt, put into the mold, turn over once at 0.5h, 6h, 22h, and then stand at 18°C for 12h ;

[0085] (7) Take the curd block out of the mold and let it stand for 10 minutes;

[0086] (8) Spread 2mL of Mucorales racemosus spores evenly on the surface of every 250g of curd (wherein, t...

Embodiment 3

[0090] (1) Standardize the qualified raw milk so that the mass ratio of protein to fat is 0.85;

[0091] (2) Pasteurization, the sterilization condition is 72°C / 15s, cooled to 30°C

[0092] (3) Add MA14 starter, carry out acidification fermentation at 200U / 1000L, and add Monascus culture solution at the same time (making the number of Monascus bacteria in the raw milk be 5×10 7 cfu / L); when the pH drops to 6.2 as the end point of acidification fermentation;

[0093] (4) Add 0.08% (w / v) of red yeast rice flour and stir thoroughly;

[0094] (5) Add calf rennet, stir for 5 minutes and let it stand, after curdling for 25 minutes, cut the curd into 2.2cm 3 small pieces, stirred slowly for 25min;

[0095] (6) Drain 50% of the whey, when the pH value drops to 5.4, drain the whey, add 3.0% salt, put it into the mold, turn it over at 0.5h, 5h, and 20h, and then stand it at 18°C 12h;

[0096] (7) Take the curd block out of the mold and let it stand for 10 minutes;

[0097] (8) Spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bacteria | aaaaa | aaaaa |

| Bacteria | aaaaa | aaaaa |

| Bacteria | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com