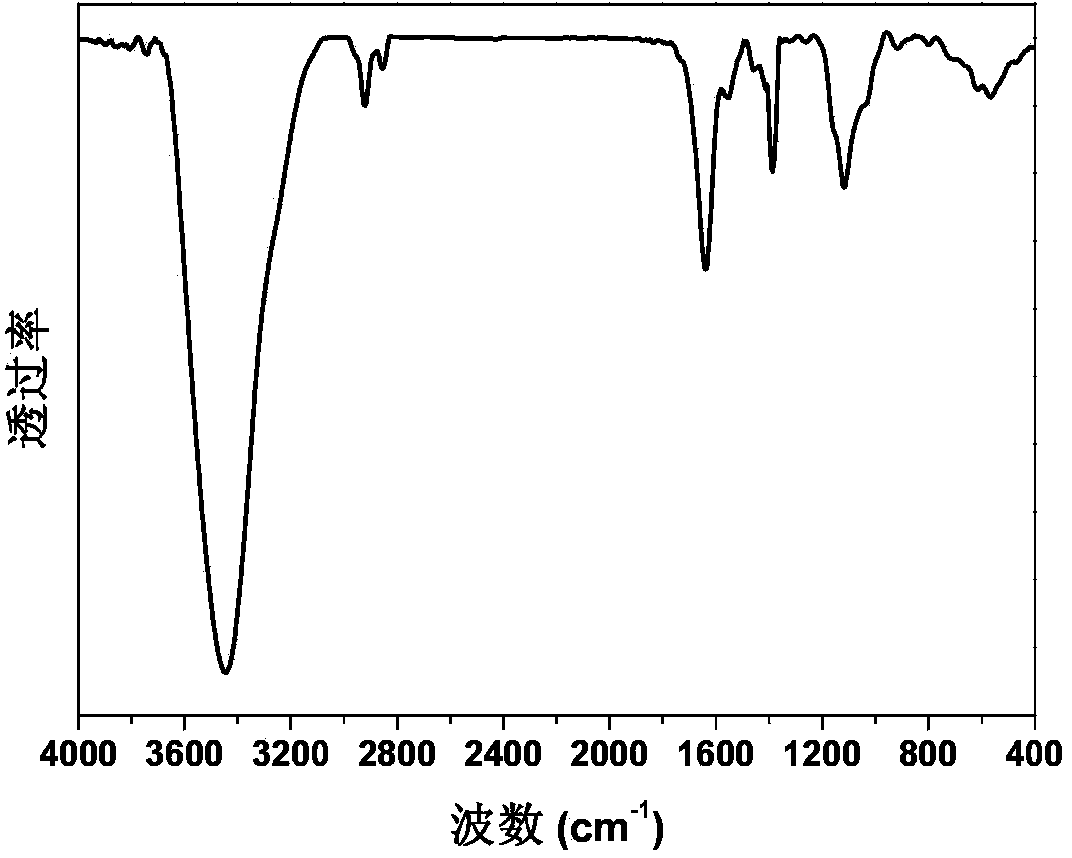

Preparation method of salt-resistant water-absorbent resin with high water absorption rate

A water-absorbent resin and superabsorbent technology, applied in the field of preparation of salt-resistant water-absorbent resin, can solve the problems of complex preparation method of superabsorbent resin, single product function, poor absorption capacity, etc. , the effect of convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a salt-resistant water-absorbing resin with a high water absorption rate, the steps are as follows:

[0038] (1) Measure 50ml of water and add it to a four-neck bottle equipped with a stirrer, nitrogen pipe, vent pipe and thermometer, weigh 10.0g of monomer acrylic acid into the water, stir at room temperature until completely dissolved,

[0039] (2) Weigh 2.5g monomer 2-acrylamido-2-methylpropanesulfonic acid into the system prepared in step (1), stir at room temperature until completely dissolved,

[0040] (3) Add 0.2 g of nano-silica to the system prepared in step (2) and stir at room temperature until completely dissolved; use a pipette to measure 200 μl of N,N′-methylenebis Acrylamide solution was added to the above mixture,

[0041] (4) Use sodium hydroxide to adjust the neutralization degree of the system prepared in step (3) to 80%. Use a pipette to measure 500 μl of ammonium persulfate solution with a concentration of 1mol / L and add it ...

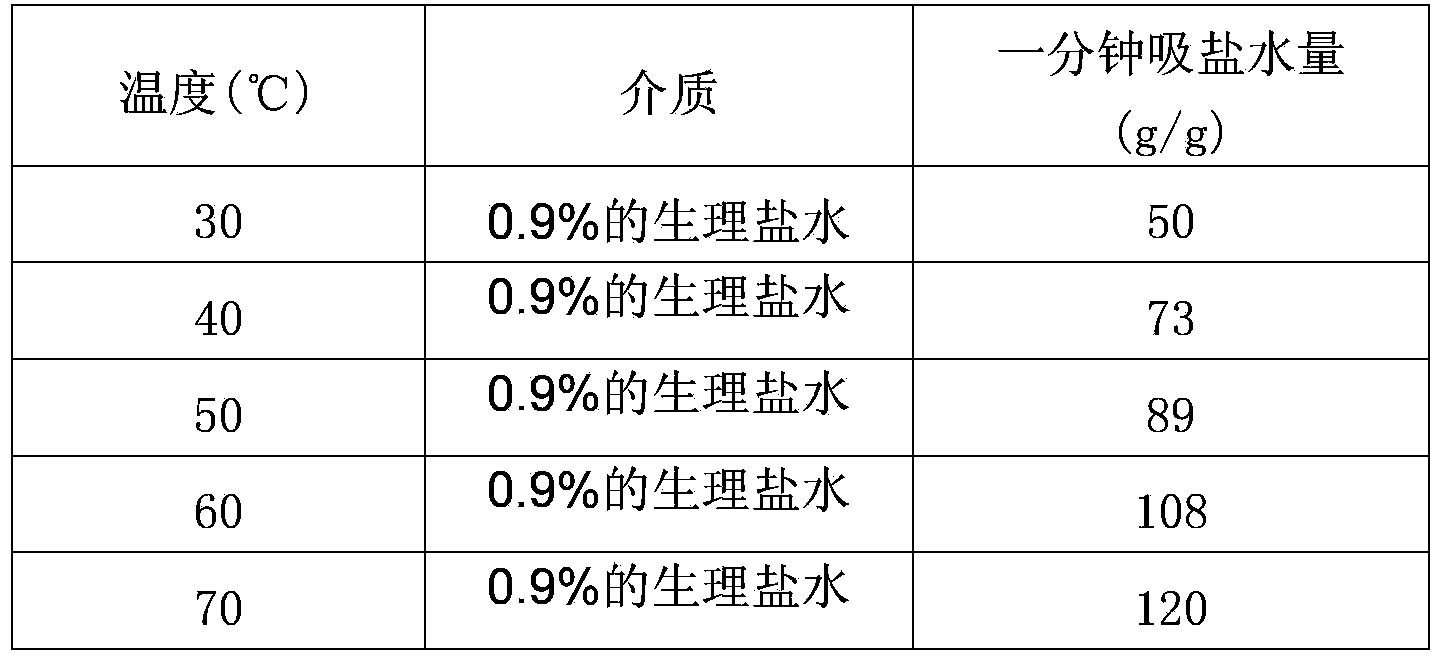

experiment example 1

[0046] The product of Example 1 was tested for its ability to absorb water and salt water for one minute.

[0047] One-minute water absorption test: Weigh 0.2g sample (accurate to 0.005g), put it into a 250-mesh 8×5cm seamless heat-sealed non-woven bag that has been weighed, and place it at the target temperature (30°C, 40°C, 50°C ℃, 60℃, 70℃) in pure water, hang the cloth bag after 60±1 seconds, let it drip freely for 10±1min, and measure the weight. The test results are shown in Table 1 and Table 2.

[0048] Table 1 One-minute water absorption capacity of the water-absorbent resin of Example 1

[0049] temperature(℃)

[0050] It can be seen from Table 1 that the water absorption of the water-absorbing resin of Example 1 in pure water first increases and then decreases with the increase of temperature, and then the water absorption remains stable with the increase of temperature. The water absorption capacity of the water-absorbent resin in one minute can reach up...

Embodiment 2

[0056] A preparation method of a salt-resistant water-absorbing resin with a high water absorption rate, as described in Example 1, the difference is:

[0057] The amount of monomer added, the amount of monomer acrylic acid added is 9.125g, the amount of monomer 2-acrylamido-2-methylpropanesulfonic acid added is 3.125g, and finally 11.9g of salt-resistant water-absorbing compound with high water absorption rate is obtained. resin powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com