High-strength polymer nanoribbons and preparation method thereof

A polymer and nanoribbon technology, applied in the field of high-strength polymer nanoribbon and its preparation, can solve the problems of increased raw material cost, complex process, low strength of nanoribbon, etc., to achieve industrial production, simple preparation process, excellent mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of polymer nanoribbons

[0044] Dissolve 1.06 grams of p-xylene in 100 mL of nitrobenzene, add 13.4 grams of anhydrous aluminum trichloride, stir evenly, add 2.0 grams of dichloromethane, stir and react for 2 hours, and then transfer to a polytetrafluoroethylene reactor. Raise the temperature to 100°C to react for 12 hours, naturally cool, filter, wash with ethanol, and dry to obtain a brown-black spongy powder.

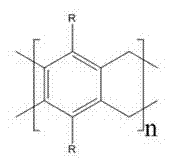

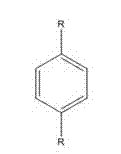

[0045] The chemical equation of this reaction is as follows (other embodiments are similar):

[0046]

[0047] (2) Calculation of nanoribbon strength

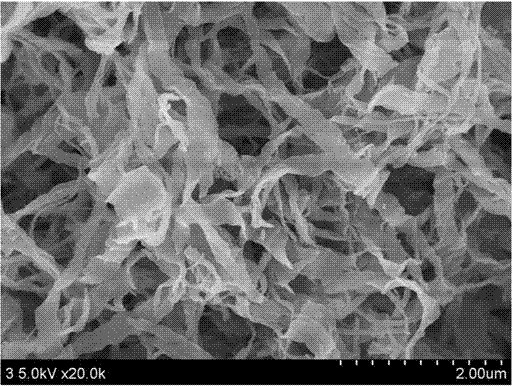

[0048] Using the molecular dynamics method, using MOPAC (2012 version) to simulate the stretching of the above-mentioned ladder molecular chain, the elastic modulus of the molecular chain is calculated to be as high as 550 GPa, figure 1 It is a scanning electron micrograph of the polymer nanobelt obtained in Example 1.

Embodiment 2

[0050] (1) Preparation of polymer nanoribbons

[0051] Dissolve 1.34 grams of p-diethylbenzene in 100 mL of nitrobenzene, add 6.4 grams of boron trifluoride, stir evenly, add 2.0 grams of dichloromethane, stir and react for 2 hours, then transfer to a polytetrafluoroethylene reactor, React at 100°C for 12 hours, filter after natural cooling, wash with ethanol, and dry to obtain a brown-black spongy powder.

[0052] (2) Calculation of nanoribbon strength

[0053] Using the molecular dynamics method and using MOPAC (2012 version) to simulate the stretching of the above-mentioned ladder molecular chain, the elastic modulus of the molecular chain is calculated to be as high as 431 GPa.

Embodiment 3

[0055] (1) Preparation of polymer nanoribbons

[0056] Dissolve 1.10 grams of hydroquinone in 100 mL of water, add 10 grams of concentrated sulfuric acid, stir well, add 2.0 grams of dichloromethane, stir well, then transfer to a polytetrafluoroethylene reactor, react at 190 ° C for 12 hours, after natural cooling Filter, wash with ethanol, and dry to obtain brown-black spongy powder.

[0057] (2) Calculation of nanoribbon strength

[0058] Using the molecular dynamics method and using MOPAC (2012 version) to simulate the stretching of the above-mentioned ladder molecular chain, the elastic modulus of the molecular chain is calculated to be as high as 570 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com