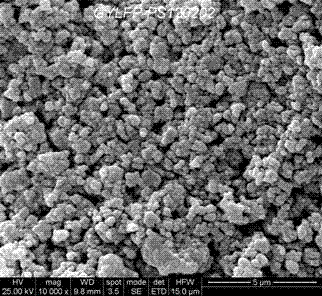

Preparation method for nanoscale lithium iron phosphate

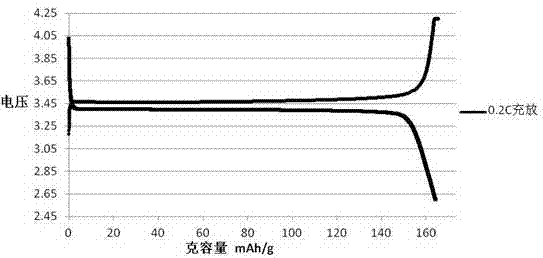

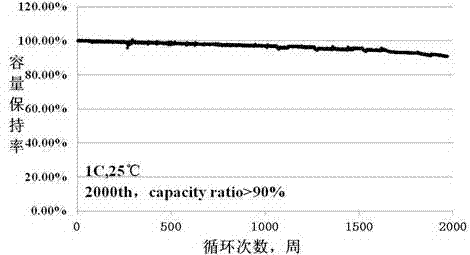

A lithium iron phosphate, nano-scale technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of uneven coating, inability to nano-scale, and insufficient product purity, and achieve higher purity and higher conductivity. , the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Raw material Fe(OH) 3 Synthesis

[0028] Weigh 0.1mol Fe(NO 3 ) 3 Dissolve in 300ml water, stir until completely dissolved to obtain a yellow clear solution, weigh 20g ammonia water dropwise and add it to a beaker to form a reddish brown precipitate. During the precipitation process, use magnetic stirring and vigorously stir to make the precipitation complete. After adding the ammonia water, continue to stir for 5 minutes. Fe(OH) 3 The precipitate was filtered and washed for several times, then transferred to an oven at 105°C for vacuum drying, ready for use.

[0029] 2. Synthesis of lithium iron phosphate precursor

[0030] Add 0.15mol Fe(OH) into a round bottom flask filled with N2 3 And add 0.15mol of H 3 PO 4 In a water bath, the temperature was 70°C for stirring reaction, and the ultrasound was turned on for 1.5 hours. The reaction color changed from red to milky white slurry precipitation. Weigh 2 g of ascorbic acid and add it to the round-bottomed flask, and contin...

Embodiment 2

[0035] 1. Raw material Fe(OH) 3 Synthesis

[0036] Weigh 0.1mol Fe(NO 3 ) 3 Dissolve in 300ml water, stir until completely dissolved to obtain a yellow clear solution, weigh 20g ammonia water dropwise and add it to a beaker to form a reddish brown precipitate. During the precipitation process, use magnetic stirring and vigorously stir to make the precipitation complete. After adding the ammonia water, continue to stir for 5 minutes. Fe(OH) 3 The precipitate was filtered and washed for several times, then transferred to an oven at 105°C for vacuum drying, ready for use.

[0037] 2. Synthesis of lithium iron phosphate precursor

[0038] N in the pass 2 Add 0.15mol Fe(OH) to the round bottom flask 3 And add 0.15mol of H 3 PO 4 In a water bath, the temperature was 70°C for stirring reaction, and the ultrasound was turned on for 1.5 hours. The reaction color changed from red to milky white slurry precipitation. Weigh 2g of hydrazine hydrate and add it to the round-bottomed flask, contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com