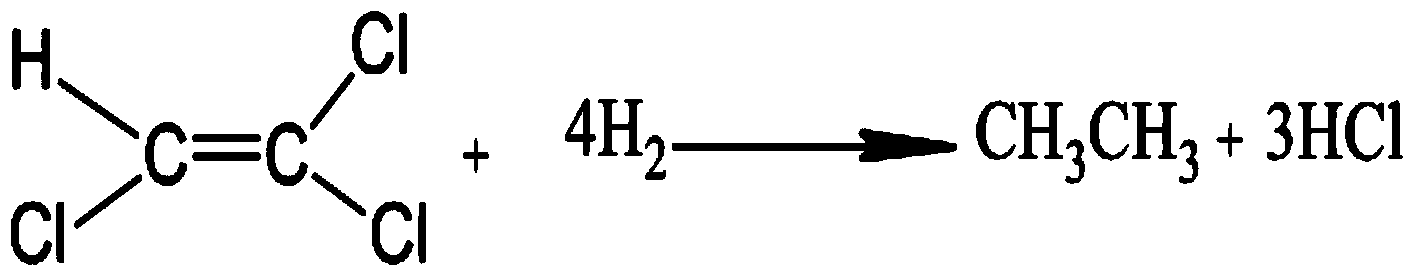

Hydrodechlorination method of trichloro ethylene

A technology of trichlorethylene and hydrodechlorination, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high price and scarce resources, and achieve low cost, technical feasibility, The effect of good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The MoP catalyst was prepared by a temperature-programmed reduction method, and trichlorethylene was hydrodechlorinated by an in-line reaction. The specific method is: according to the atomic ratio of MoP (molybdenum: phosphorus = 1:1), weigh 4.00 g of ammonium molybdate and 3.00 g of diammonium hydrogen phosphate, mix and dissolve in 30 ml of distilled water until the solution is clear, and obtain a molybdenum phosphorus aqueous solution. The solution was evaporated to dryness in a water bath to obtain a molybdenum-phosphorus white mixture powder, which was dried overnight at 120° C. and calcined at 500° C. for 5 hours to obtain a blue precursor. The precursor is ground, pressed into tablets and sieved to obtain 20-40 mesh particles. Take 1ml of the particle and fill it in the middle of the quartz tube, 2 Under the atmosphere, the particles were raised to 300°C in 0.5h, and then at 1°C min -1 The rate was increased to 650°C and kept at this temperature for 2h. Then ...

Embodiment 2

[0026] The difference between this embodiment and Example 1 is that the hydrodechlorination reaction time is 3h, and the H 2 Passing time is identical with reaction time, and others are identical with embodiment 1. The HCl generated by the reaction was collected, and the conversion rate of trichlorethylene was calculated to be 27.17%.

[0027] It can be seen that the conversion rate of trichlorethylene is obviously improved by prolonging the reaction time.

Embodiment 3

[0029] The difference between this example and Example 1 is that the hydrodechlorination reaction temperature is 300° C., and the others are the same as Example 1. The HCl generated by the reaction was collected, and the conversion rate of trichlorethylene was calculated to be 12.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com