Modified monomer and organic modified polysiloxane prepared thereby

A polysiloxane and organosilicon technology, applied in organic chemistry, silicon organic compounds, cosmetic preparations, etc., can solve the problems of unfavorable target product synthesis, many telomerization steps, low degree of polymerization, etc., and achieve a wide range of products , Strong designability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

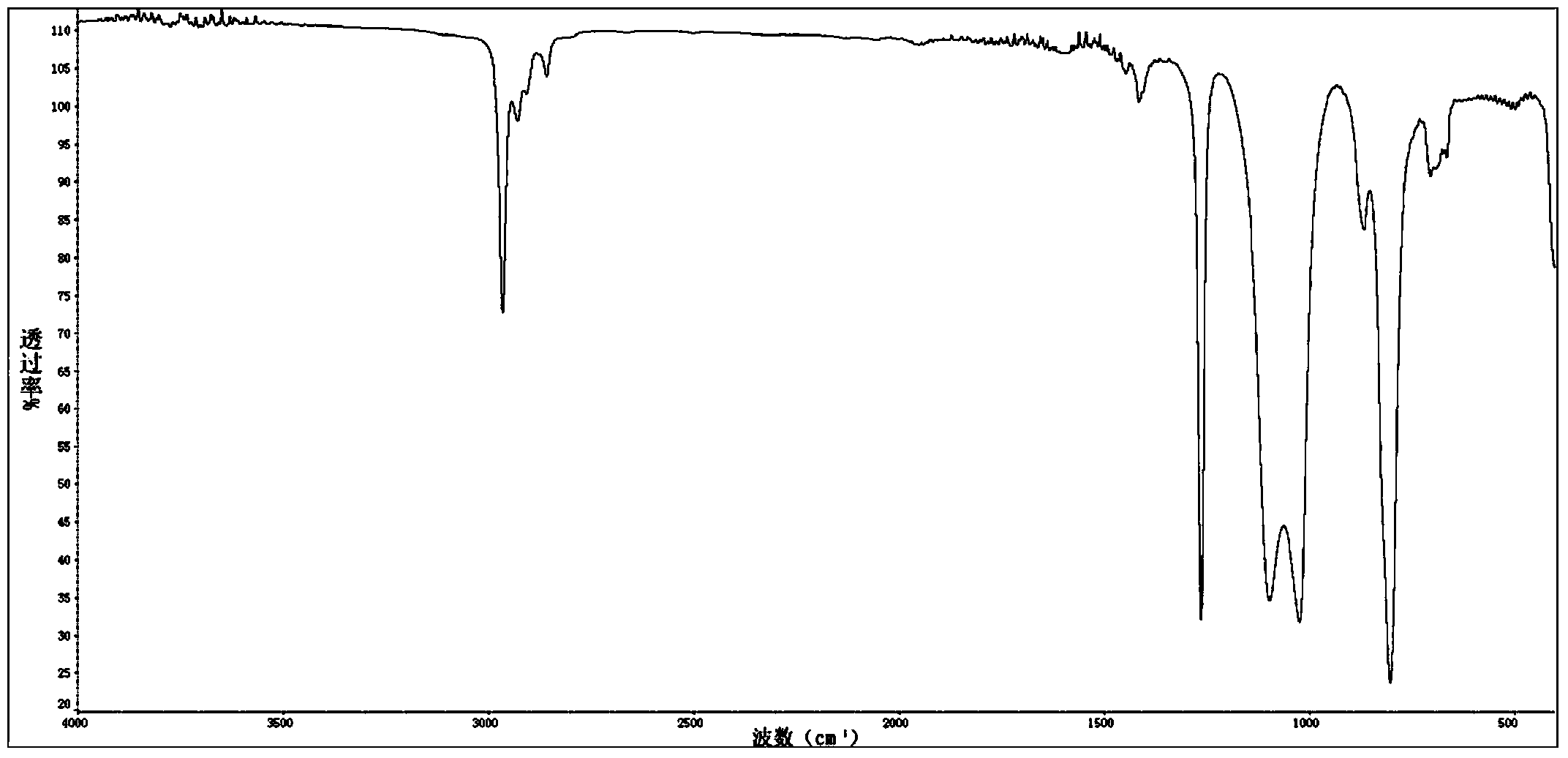

Image

Examples

Embodiment 1

[0055] Take by weighing 162.3g stearyl alcohol and join into 500mL four-necked flask (the four-necked flask is equipped with thermometer, reflux device, stirring device and nitrogen (N 2 ) lead-in device, where the return device is interchangeable with the vacuum device as required), N 2 Add 0.15g of tetramethylammonium hydroxide pentahydrate under the atmosphere, turn on the vacuum pump, control the vacuum at -0.08MPa, slowly raise the temperature to 60°C and melt the material. After the melting is completed, stir and dehydrate for 1 hour. After the dehydration is completed, release the vacuum, N 2 Under the atmosphere, use a reflux device instead, raise the temperature to 65°C, and add 54.2g of tetramethyldihydrodisiloxane dropwise within 1 hour. After the addition, raise the temperature to 70°C, and react for 2 hours. After the reaction, the temperature was raised to 140° C. and kept for 1.5 hours to decompose the catalyst to obtain the modified monomer.

Embodiment 2

[0057] Take by weighing 145.47g palmitic alcohol and join into 500mL four-necked flask (the four-necked flask is equipped with thermometer, reflux device, stirring device and N 2 induction unit, where the return unit is interchangeable with the vacuum unit as required), N 2 Add 0.12g of tetramethylammonium hydroxide pentahydrate under the atmosphere, turn on the vacuum pump, control the vacuum at -0.095MPa, slowly raise the temperature to 55°C and melt the material. After the melting is completed, stir and dehydrate for 1.5h. After the dehydration is completed, release the vacuum, N 2 Under the atmosphere, use a reflux device instead, raise the temperature to 50°C, add 52.7g of tetramethyldihydrodisiloxane dropwise within 2h, and then raise the temperature to 80°C, and react for 1.5h. After the reaction, the temperature was raised to 150° C. and kept for 1 hour to decompose the catalyst to obtain the modified monomer.

Embodiment 3

[0059] Weigh 200g of polyether polyol (hydroxyl value 60mg KOH / g) into a 500mL four-necked flask (the four-necked flask is equipped with a thermometer, reflux device, stirring device and N 2 induction unit, where the return unit is interchangeable with the vacuum unit as required), N 2 Add 0.12g of tetramethylammonium hydroxide pentahydrate under the atmosphere, turn on the vacuum pump, control the vacuum at -0.09MPa, slowly raise the temperature to 50°C and melt the material. After the melting is completed, stir and dehydrate for 2 hours. After the dehydration is completed, release the vacuum, N 2 Under the atmosphere, use a reflux device instead, raise the temperature to 80°C, add 13.2g of 2,4,6,8-tetramethylcyclotetrasiloxane dropwise within 1 hour, and then raise the temperature to 100°C to react 1h. After the reaction, the temperature was raised to 160°C and kept for 0.5h to decompose the catalyst to obtain the modified monomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com